TS24-LC5 模组规格书

更新时间:2025-04-16 12:57:44下载pdf

TS24-LC5 是由涂鸦智能开发的一款 Matter over Thread 模组。它由一颗高集成度的无线射频处理器芯片 EFR32MG24 和少量外围器件构成,内置了 802.15.4 PHY/MAC Thread 网络协议栈和丰富的库函数。

产品概述

TS24-LC5 内嵌低功耗的 32 位 ARM Cortex-M33 内核,1536 KByte 闪存程序存储器,192KB RAM 数据存储器和丰富的外设资源,集成了所有的 Thread MAC 以及 TCP/IP 协议的函数库。用户可以基于这些开发满足自己需求的嵌入式 Thread 产品。

特性

- 内置低功耗 32 位 CPU,ARM Cortex-M33 处理器,带有 DSP 指令和浮点单元可以兼作应用处理器

- 主频支持 78 MHz

- 宽工作电压:2.0 V–3.8 V

- 外设:3×GPIOs

- Thread 连通性

- 支持 802.15.4 MAC/PHY

- 工作信道 11 - 26@2.400-2.483GHz,空口速率 250Kbps

- 最大 +19dBm 的输出功率

- 35μA/MHz 运行时功耗,5μA 休眠电流

- 外接单极子天线,天线增益 2.1dBi

- 工作温度:-40℃ 到 105℃

- 支持硬件加密,支持 AES 128/256

应用领域

- 智能楼宇

- 智慧家居、家电

- 智能插座、智慧灯

- 工业无线控制

- 婴儿监控器

- 网络摄像头

- 智能公交

更新说明

| 更新日期 | 更新内容 | 更新后版本 |

|---|---|---|

| 2022-09-09 | 新建规格书文档 | V1.0.0 |

模组接口

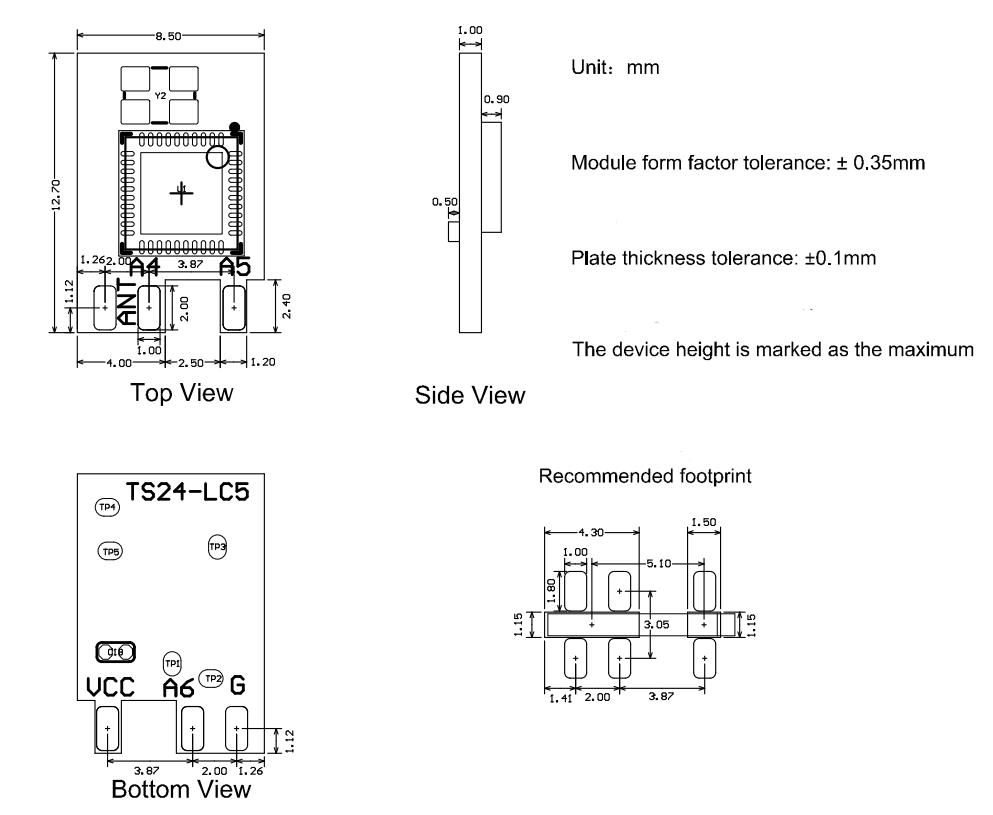

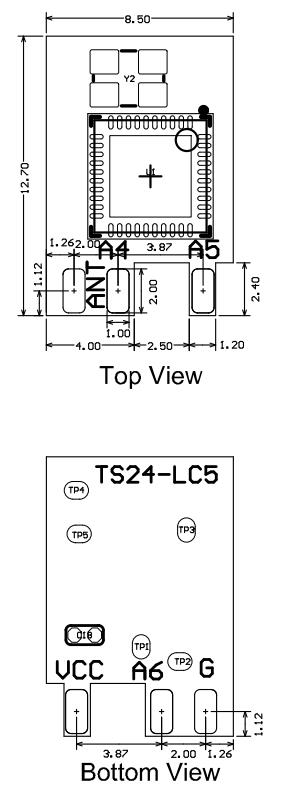

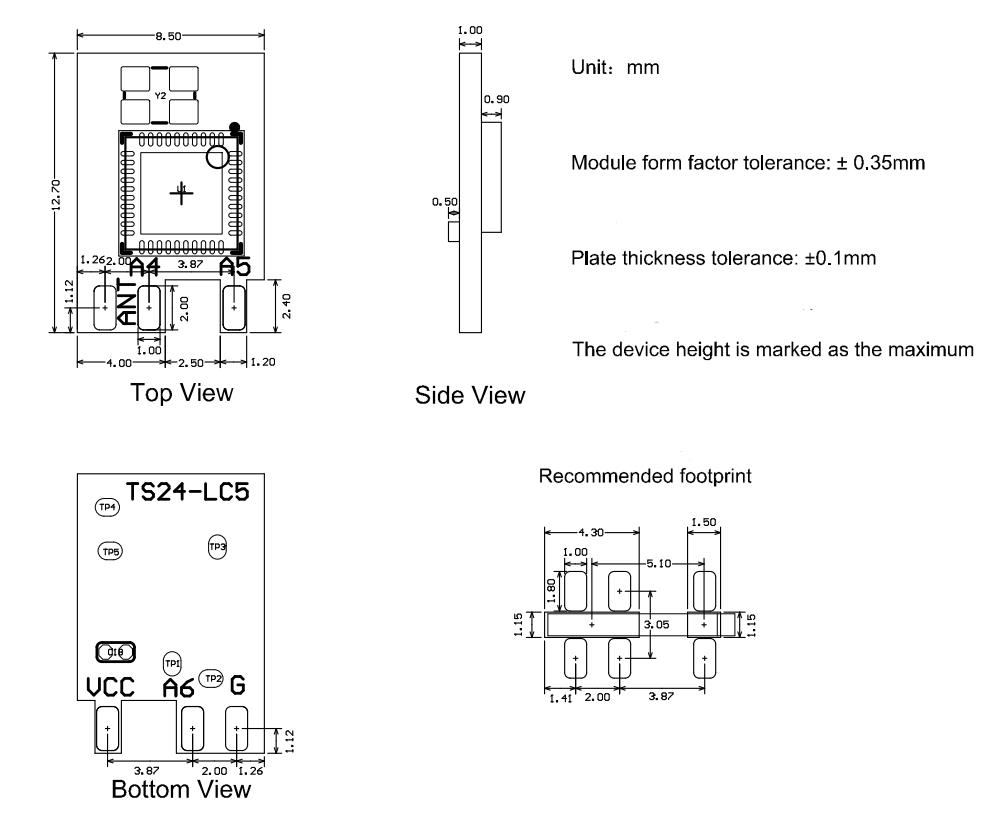

尺寸封装

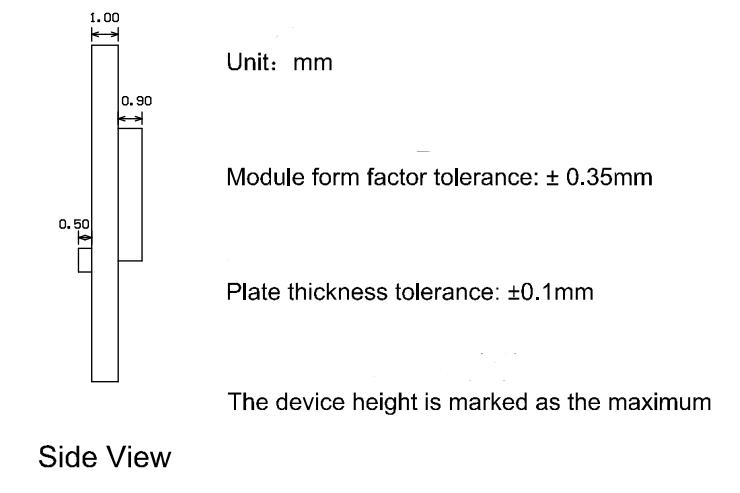

-

TS24-LC5 共有 2 排引脚。

-

TS24-LC5 尺寸大小:12.7±0.3mm (W)×8.5±0.3mm (L) ×2.3±0.15mm (H)。

TS24-LC5 尺寸如下图所示:

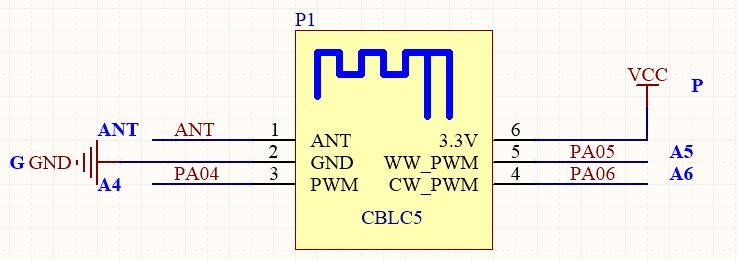

引脚定义

| 引脚序号 | 符号 | IO 类型 | 功能 |

|---|---|---|---|

| 1 | ANT | I/O | 射频口,此焊盘用于焊接天线 |

| 2 | GND | P | 模组的参考地,需保证接地良好。 |

| 3 | PA04 | I/O | 支持硬件 PWM,对应 IC 的 PA04(Pin25) |

| 4 | PA06 | I/O | 支持硬件 PWM,对应 IC 的 PA06(Pin27) |

| 5 | PA05 | I/O | 支持硬件 PWM,对应 IC 的 PA05(Pin26) |

| 6 | VCC | P | 模组的电源供电引脚(典型供电电压:3.3V) |

- P 表示电源引脚,I/O 表示输入输出引脚。

测试点定义

| 引脚序号 | 符号 | IO类型 | 功能 |

|---|---|---|---|

| TP1 | SWDIO | I/O | JLINK SWDIO 烧录管脚。 |

| TP2 | SWCLK | I/O | JLINK SWCLK 烧录管脚。 |

| TP3 | RST | I | 低电平时模组被复位住,正常状态下高电平。 |

| TP4 | TX | I/O | TX,串口发射,对应 IC PD03(pin37)。 |

| TP5 | RX | I/O | RX,串口接收,对应 IC PD02(pin38)。 |

说明:测试引脚不推荐使用。

电气参数

绝对电气参数

| 参数 | 描述 | 最小值 | 最大值 | 单位 |

|---|---|---|---|---|

| Ts | 存储温度 | -50 | 150 | ℃ |

| VBAT | 供电电压 | 2.0 | 3.8 | V |

| 静电释放电压(人体模型) | TAMB-25℃ | - | 2 | KV |

| 静电释放电压(机器模型) | TAMB-25℃ | - | 0.5 | KV |

正常工作条件

| 参数 | 描述 | 最小值 | 典型值 | 最大值 | 单位 |

|---|---|---|---|---|---|

| Ta | 工作温度 | -40 | - | 105 | ℃ |

| VCC | 工作电压 | 2.0 | 3.3 | 3.8 | V |

| VIL | IO 低电平输入 | - | - | IOVDD*0.3 | V |

| VIH | IO 高电平输入 | IOVDD*0.7 | - | - | V |

| VOL | IO 低电平输出 | - | - | IOVDD*0.2 | V |

| VOH | IO 高电平输出 | IOVDD*0.8 | - | - | V |

连续发射和接收时功耗

| 工作状态 | 模式 | 速率 | 发射功率/接收 | 平均值 | 峰值(典型值) | 单位 |

|---|---|---|---|---|---|---|

| 发射 | - | 250Kbps | +19dBm | 178 | 180 | mA |

| 发射 | - | 250Kbps | +10dBm | 59 | 60 | mA |

| 发射 | - | 250Kbps | +0dBm | 24 | 25 | mA |

| 接收 | - | 250Kbps | 连续接收 | 10.5 | 12.7 | mA |

工作电流

| 工作模式 | 工作状态,Ta=25℃ | 平均值 | 最大值(典型值) | 单位 |

|---|---|---|---|---|

| 快连配网状态 | 模组处于快连配网状态 | 10.3 | 16.5 | mA |

| 网络连接状态 | 模组处于联网空闲状态 | 10.4 | 42 | mA |

| 网络连接状态 | 模组处于联网工作状态 | 12.1 | 42 | mA |

| 深度睡眠模式 | 深度睡眠模式,保留 64KB Flash | 5 | - | μA |

射频参数

基本射频特性

| 参数项 | 详细说明 |

|---|---|

| 工作频率 | 2.405~2.480GHz |

| Zigbee 标准 | IEEE 802.15.4 |

| 数据传输速率 | 250Kbps |

| 天线类型 | 外接单极子天线,天线增益 2.1dBi |

发射性能

TX 连续发送性能

| 参数项 | 最小值 | 典型值 | 最大值 | 单位 |

|---|---|---|---|---|

| 输出功率(250Kbps) | -30 | 15 | 19 | dBm |

| 输出功率调节步进 | - | 0.5 | 1 | dBm |

| 输出频谱临道抑制度 | - | -31 | - | dBc |

| 频率误差 | -15 | - | 15 | ppm |

接收性能

RX 灵敏度

| 参数项 | 最小值 | 典型值 | 最大值 | 单位 |

|---|---|---|---|---|

| PER<8%,RX 灵敏度(250Kbps) | -104 | -104 | -103 | dBm |

天线信息

天线类型

外置天线,采用焊接方式焊接在模组 ANT 焊盘上。

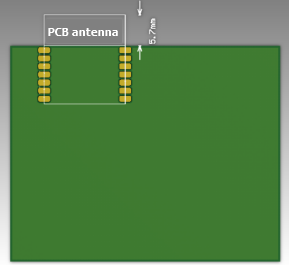

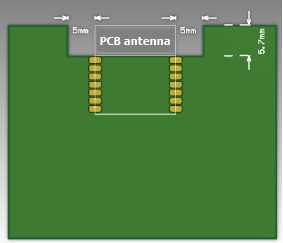

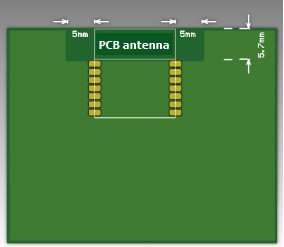

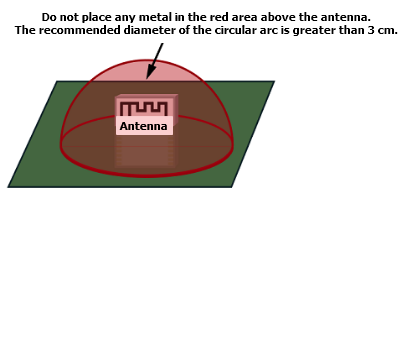

降低天线干扰

在 Thread 模组上使用单极子天线时,为确保射频辐射性能的最优化,建议模组天线部分和其他金属件距离至少在 15mm 以上。

用户 PCB 板载天线区域勿走线甚至覆铜,以免影响天线性能。

封装信息及生产指导

机械尺寸

PCB 尺寸大小:12.7±0.3mm (W)×8.5±0.3mm (L) ×2.3±0.15mm (H)。

侧视图

原理图封装

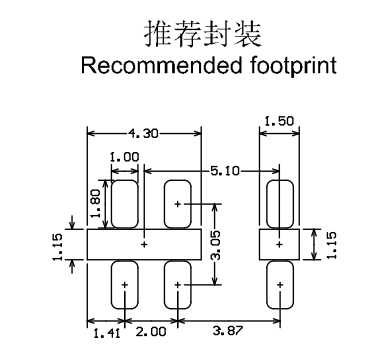

推荐封装

生产指南

-

涂鸦出厂的直插式模组建议优先使用波峰焊接设备焊接,在无法使用波峰焊接设备焊接时才使用手工焊接,拆开包装后建议在 24 小时内完成焊接,否则需放置在湿度不超过 10%RH 的干燥柜内,或重新进行真空包装并记录暴露时间,总暴露时间不超过 168 小时。

-

焊接所需设备和材料:

- 波峰焊设备

- 波峰焊接治具

- 恒温烙铁

- 锡条、锡丝、助焊剂

- 炉温测试仪

-

烘烤所需仪器或设备:

- 柜式烘烤箱

- 防静电耐高温托盘

- 防静电耐高温手套

-

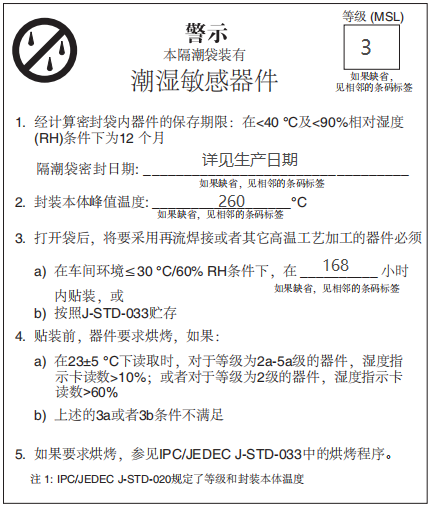

涂鸦出厂的模组当出现可能受潮的情况下需要进行烘烤:

- 拆封前发现真空包装袋破损。

- 拆封后发现包装袋内没有湿度指示卡。

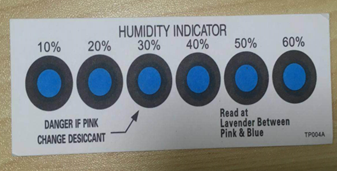

- 拆封后如果湿度指示卡读取到 10% 及以上色环变为粉色。

- 拆封后总暴露时间超过 168 小时。

- 从首次密封包装之日起超过 12 个月。

-

烘烤参数如下:

- 烘烤温度:卷盘包装 40℃,小于等于 5%RH。托盘包装 125℃,小于等于 5%RH(耐高温托盘非吸塑盒拖盘)。

- 烘烤时间:卷盘包装 168 小时,托盘包装 12 小时。

- 报警温度设定:卷盘包装 50℃,托盘包装 135℃。

- 自然条件下冷却到 36℃ 以下后,即可进行生产。

- 若烘烤后暴露时间大于 168 小时没有使用完,请再次进行烘烤。

- 如果暴露时间超过 168 小时未经过烘烤,不建议使用波峰焊接工艺焊接此批次模组,因模组为 3 级湿敏器件超过允许的暴露时间很可能受潮,进行高温焊接时可能导致器件失效或焊接不良。

-

在整个生产过程中请对模组进行静电放电(ESD)保护。

-

为了确保产品的良好品质,生产时需重点关注助焊剂的喷涂量、波峰高度、波峰焊锡缸内的锡渣和铜含量是否超标,波峰焊接治具开窗和治具厚度是否合适以及波峰焊接炉温曲线的合理性。

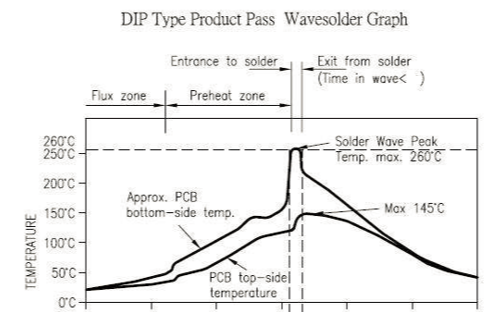

推荐炉温曲线和温度建议

请参考波峰焊接炉温建议进行炉温设定,峰值温度 260℃±5℃,波峰焊接温度曲线如下图所示:

焊接温度建议:

| 波峰焊接炉温曲线建议 | 手工焊接温度建议 | ||

|---|---|---|---|

| 预热温度 | 80-130℃ | 焊接温度 | 360℃±20℃ |

| 预热时间 | 75-100S | 焊接时间 | 小于 3S/点 |

| 波峰接触时间 | 3-5S | NA | NA |

| 锡缸温度 | 260±5℃ | NA | NA |

| 升温斜率 | ≤2℃/S | NA | NA |

| 降温斜率 | ≤6℃/S | NA | NA |

储存条件

涂鸦出厂的模组存储条件如下:

-

防潮袋真空包装储存在温度 <40℃、湿度 <90%RH 的环境中。

-

干燥包装的产品,保质期为从包装密封之日起 12 个月的时间。

-

密封包装内装有湿度指示卡:

模组 MOQ 与包装信息

| 产品型号 | MOQ(pcs) | 出货包装方式 | 每个卷盘存放模组数 | 每箱包装卷盘数 |

|---|---|---|---|---|

| TS24-LC5 | 6000 | 载带卷盘 | 1500 | 4 |

该内容对您有帮助吗?

是意见反馈该内容对您有帮助吗?

是意见反馈