BTU 模组规格书

更新时间:2026-01-06 06:40:51下载pdf

BTU 是由涂鸦智能开发的一款低功耗嵌入式蓝牙模组。它主要由一个高集成度的蓝牙芯片 TLSR8250 和少量的外围电路构成,内置了蓝牙网络通信协议栈和丰富的库函数。

产品概述

BTU 还包含低功耗的 32 位 MCU、蓝牙 LE5.0/2.4G Radio、4Mbits flash 和 48Kbyte SRAM.

特点

- 内置低功耗 32 位 MCU,可以兼作应用处理器。

- 主频支持 48 MHz

- 工作电压:3.0V-3.6V

- 外设:15×GPIOs、1×UART、2×ADC

- 蓝牙 LE RF 特性

- 兼容蓝牙 LE 4.2/5.0

- TX 发射功率:+10dBm

- RX 接收灵敏度:-94.5dBm@蓝牙 LE 1Mbps

- 内嵌硬件 AES 加密

- 搭配板载 PCB 天线,天线增益 1.1dB

- 工作温度:-40℃ 到 +85℃

应用领域

- 智能楼宇

- 智慧家居/家电

- 智能插座、智慧灯

- 工业无线控制

- 婴儿监控器

- 智能公交

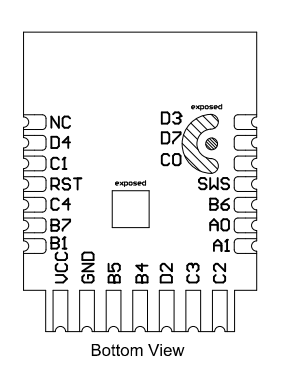

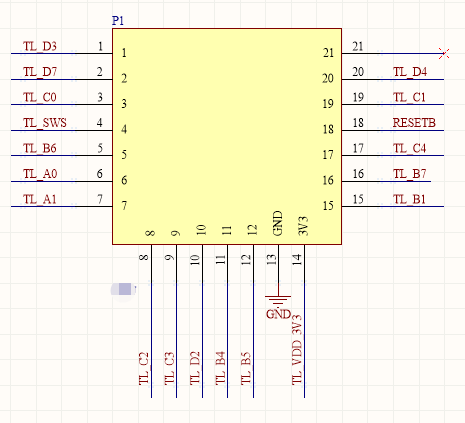

模组接口

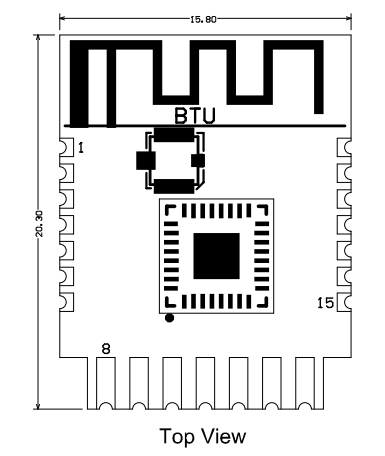

尺寸封装

BTU 共有 3 排引脚,引脚间距为 1.4±0.1mm。

BTU 尺寸大小:20.3±0.35mm (L) × 15.8±0.35mm (W) × 3.0±0.15mm (H)。

引脚定义

| 引脚序号 | 符号 | I/O 类型 | 功能 |

|---|---|---|---|

| 1 | D3 | I/O | 普通 IO 引脚,对应 IC 的 D3(Pin32) |

| 2 | D7 | I/O | 普通 IO 引脚,对应 IC 的 D7(Pin2) |

| 3 | C0 | I/O | 普通 IO 引脚,对应 IC 的 C0(Pin20) |

| 4 | SWS | I/O | 烧录引脚,对应 IC 的 SWS(Pin5) |

| 5 | B6 | I | ADC 引脚,对应 IC 的 B6(Pin16) |

| 6 | A0 | I/O | 普通 IO 引脚,对应 IC 的 A0(Pin3) |

| 7 | A1 | I/O | 普通 IO 引脚,对应 IC 的 A1(Pin4) |

| 8 | C2 | I/O | 支持硬件 PWM,对应 IC 的 C2(Pin22) |

| 9 | C3 | I/O | 支持硬件 PWM,对应 IC 的 C3(Pin23) |

| 10 | D2 | I/O | 支持硬件 PWM,对应 IC 的 D2(Pin31) |

| 11 | B4 | I/O | 支持硬件 PWM,对应 IC 的 B4(Pin14) |

| 12 | B5 | I/O | 支持硬件 PWM,对应 IC 的 B5(Pin15) |

| 13 | GND | P | 电源接地引脚 |

| 14 | VCC | P | 电源引脚(3.3V) |

| 15 | B1 | I/O | Uart_TXD,对应 IC 的 B1(Pin6) |

| 16 | B7 | I/O | Uart_RXD,对应 IC 的 B7(Pin17) |

| 17 | C4 | I/O | ADC 引脚,对应 IC 的 C4(Pin24) |

| 18 | RST | I/O | 复位引脚,低电平有效 |

| 19 | C1 | I/O | 普通 IO 引脚,对应 IC 的 C1(Pin21) |

| 20 | D4 | I/O | 普通 IO 引脚,对应 IC 的 D4(Pin1) |

| 21 | NC | I/O | 空接 |

说明:

P表示电源引脚,I/O 表示输入输出引脚。

电气参数

绝对电气参数

| 参数 | 描述 | 最小值 | 最大值 | 单位 |

|---|---|---|---|---|

| Ts | 存储温度 | -65 | 150 | ℃ |

| VCC | 供电电压 | -0.3 | 3.9 | V |

| 静电释放电压(人体模型) | TAMB-25℃ | - | 2 | KV |

| 静电释放电压(机器模型) | TAMB-25℃ | - | 0.5 | KV |

工作条件

| 参数 | 描述 | 最小值 | 典型值 | 最大值 | 单位 |

|---|---|---|---|---|---|

| Ta | 工作温度 | -40 | - | 85 | ℃ |

| VCC | 工作电压 | 3.0 | 3.3 | 3.6 | V |

| VIL | IO 低电平输入 | VSS | - | VCC*0.3 | V |

| VIH | IO 高电平输入 | VCC*0.7 | - | VCC | V |

| VOL | IO 低电平输出 | VSS | - | VCC*0.1 | V |

| VOH | IO 高电平输出 | VCC*0.9 | - | VCC | V |

工作模式下功耗

| 符号 | 条件 | 最大值(典型值) | 单位 |

|---|---|---|---|

| Itx | 连续发送,11.5dBm输出功率 | 22.6 | mA |

| Irx | 连续接收 | 6.5 | mA |

| IDC | Mesh 联网工作状态下 Average 值 | 6.59 | mA |

| IDC | Mesh 联网工作状态下 Peak 值 | 24.9 | mA |

| Ideepsleep1 | 深度休眠模式(保留16KBRAM) | 1.2 | μA |

| Ideepsleep2 | 深度休眠模式(不保留RAM) | 0.4 | μA |

射频参数

基本射频特性

| 参数项 | 详细说明 |

|---|---|

| 工作频率 | 2.4GHz ISM band |

| 无线标准 | 蓝牙 LE 4.2/5.0 |

| 数据传输速率 | 1 Mbps |

| 天线类型 | 板载 PCB 天线 |

RF 输出功率

| 参数项 | 最小值 | 典型值 | 最大值 | 单位 |

|---|---|---|---|---|

| RF 平均输出功率 | -21 | 10 | 11.5 | dBm |

| 20dB 调制信号带宽(1M) | - | 2500 | - | KHz |

RF 接收灵敏度

| 参数项 | 最小值 | 典型值 | 最大值 | 单位 |

|---|---|---|---|---|

| RX 灵敏度 1Mbps | - | -94.5 | - | dBm |

| 频率偏移误差 1Mbps | -250 | - | +300 | KHz |

| 同信道干扰抑制 | - | - | -10 | dB |

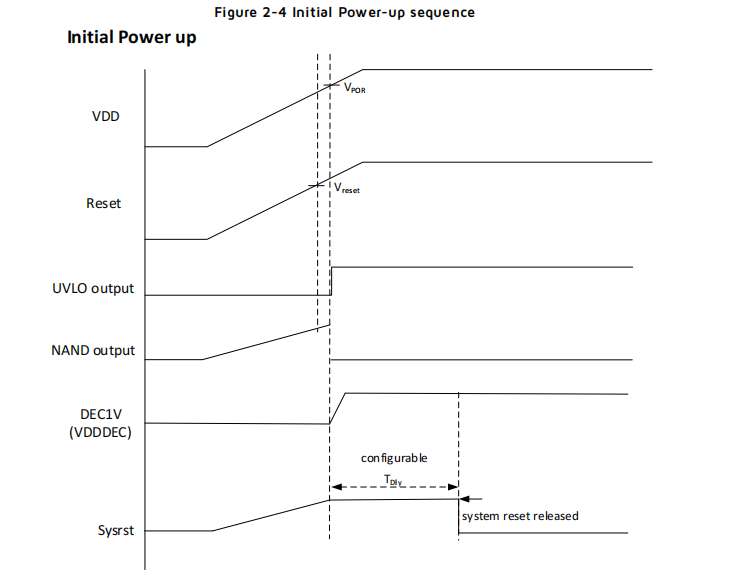

模组上电时序要求

TLSR8250 芯片对上电时序有要求,在上电过程中 RST 引脚达到 1.62V 以后系统开始启动,这时 VDD 需要在 10ms 内达到 1.8V 以上。由于 RST 引脚有 RC 链路,故裸模组在 RST 达到 1.62V 的时候 VDD 已经远超过 1.8。

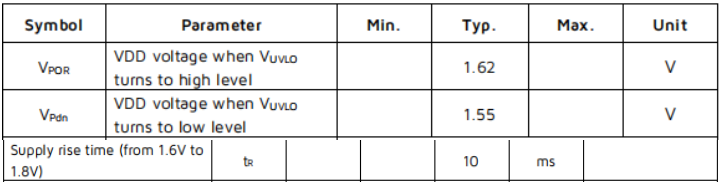

TLSR8250 芯片模组对接的电源驱动如果存在大电容的一些充放电情况下,若模组电压未完全放电到 0.6V 以下,模组再启动的话会有死机风险。要求模组 VDD_3.3V 供电引脚需要接 1K 的假负载,用来快速释放电能。可参考下面的部分电源驱动链路:

天线信息

天线类型

BTU 使用的是板载 PCB 天线,天线增益 1.1dBi。

降低天线干扰

为确保 RF 性能的最优化,建议模组天线部分和其他金属件的距离至少保持 15mm 以上。如果使用环境的天线周边包裹金属材料等,会极大地衰减无线信号,进而恶化射频性能。成品设计时,注意给天线区域预留出足够的空间。

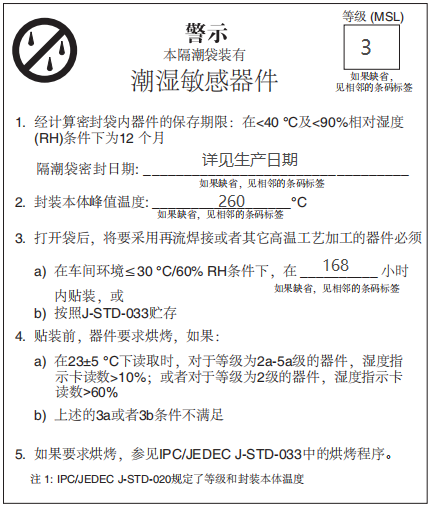

封装信息及生产指导

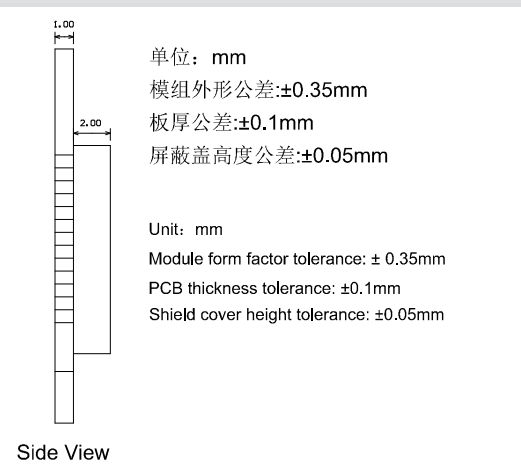

机械尺寸

PCB 尺寸大小:20.3±0.35mm (L) × 15.8±0.35mm (W) × 1.0±0.1mm (H)。

侧视图

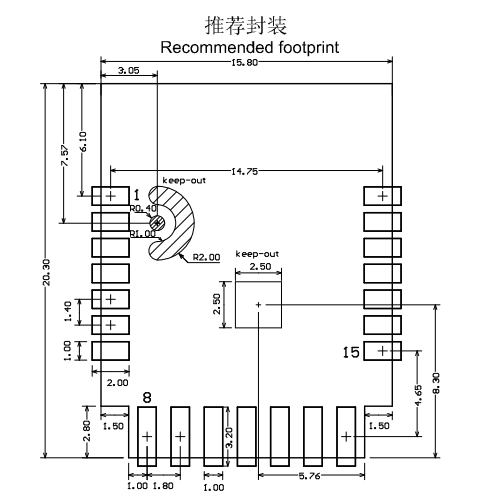

原理图封装

PCB 封装图-SMT

上图中 keep-out 示意区域,不需要上锡,不要走线。

生产指南

-

涂鸦出厂的可贴可插封装模组根据客户底板设计方案选择组装方式,底板设计为贴片封装时使用 SMT 贴片制程进行生产,如果底板设计为插件封装时使用波峰焊制程进行生产。模组产品拆开包装后建议在 24 小时内完成焊接,否则需放置在湿度不超过 10%RH 的干燥柜内,或重新进行真空包装并记录暴露时间,总暴露时间不超过 168 小时。

- (SMT 制程)SMT 贴片所需仪器或设备:

- 贴片机

- SPI

- 回流焊

- 炉温测试仪

- AOI

- (波峰焊制程)波峰焊所需的仪器或设备:

- 波峰焊设备

- 波峰焊接治具

- 恒温烙铁

- 锡条、锡丝、助焊剂

- 炉温测试仪

- 烘烤所需仪器或设备:

- 柜式烘烤箱

- 防静电耐高温托盘

- 防静电耐高温手套

- (SMT 制程)SMT 贴片所需仪器或设备:

-

涂鸦出厂的模组存储条件如下:

-

防潮袋必须储存在温度 <40℃、湿度 <90%RH 的环境中。

-

干燥包装的产品,保质期为从包装密封之日起 12 个月的时间。

-

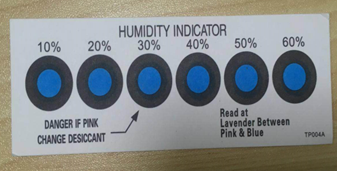

密封包装内装有湿度指示卡:

-

-

涂鸦出厂的模组当出现可能受潮的情况下需要进行烘烤:

- 拆封前发现真空包装袋破损。

- 拆封后发现包装袋内没有湿度指示卡。

- 拆封后如果湿度指示卡读取到 10% 及以上色环变为粉色。

- 拆封后总暴露时间超过 168 小时。

- 从首次密封包装之日起超过 12 个月。

-

烘烤参数如下:

- 烘烤温度:卷盘包装 40℃,小于等于 5%RH。托盘包装 125℃,小于等于 5%RH(耐高温托盘非吸塑盒拖盘)。

- 烘烤时间:卷盘包装 168 小时,托盘包装 12 小时。

- 报警温度设定:卷盘包装 50℃,托盘包装 135℃。

- 自然条件下冷却到 36℃ 以下后,即可进行生产。

- 若烘烤后暴露时间大于 168 小时没有使用完,请再次进行烘烤。

- 如果暴露时间超过 168 小时未经过烘烤,不建议使用波峰焊接工艺焊接此批次模组,因模组为 3 级湿敏器件超过允许的暴露时间很可能受潮,进行高温焊接时可能导致器件失效或焊接不良。

-

在整个生产过程中,请对模组进行静电放电(ESD)保护。

-

为了确保产品合格率,建议使用 SPI 和 AOI 测试设备来监控锡膏印刷和贴装品质。

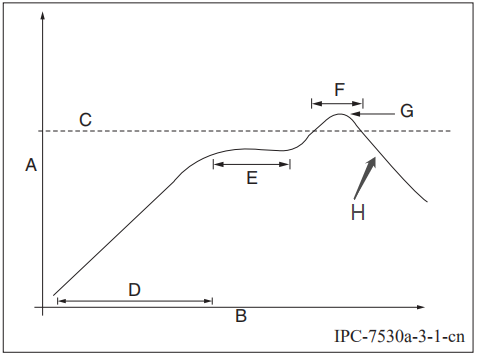

推荐炉温曲线

请根据制程选择相应的焊接方式,SMT 参考回流焊接炉温曲线推荐,波峰焊制程参考波峰焊接炉温曲线推荐。设定炉温与实测炉温有一定差距,本文所示温度均为实测温度。

方式一:SMT 制程(SMT 回流焊接推荐炉温曲线)

请参考回流焊炉温曲线要求进行炉温设定,回流焊温度曲线如下图所示:

-

A:温度轴

-

B:时间轴

-

C:合金液相线温度区间为 217-220℃

-

D:升温斜率为 1-3℃/S

-

E:恒温时间为 60-120S,恒温温度区间为 150-200℃

-

F:液相线以上时间为 50-70S

-

G:峰值温度为 235-245℃

-

H:降温斜率为 1-4℃/S

注意:以上推荐曲线以 SAC305 合金焊膏为例。其他合金焊膏请按焊膏规格书推荐炉温曲线设置。

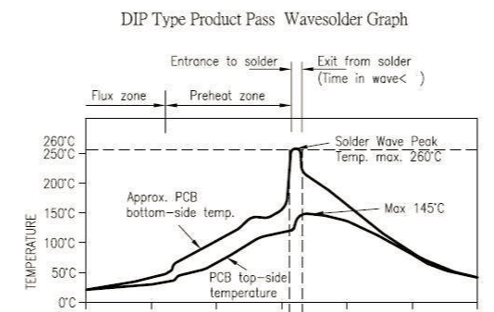

方式二:波峰焊制程(波峰焊接炉温曲线)

请参考波峰焊接炉温建议进行炉温设定,峰值温度 260℃±5℃,波峰焊接温度曲线如下图所示:

| 波峰焊接炉温曲线建议 | 手工补焊温度建议 | ||

|---|---|---|---|

| 预热温度 | 80-130℃ | 焊接温度 | 360℃±20℃ |

| 预热时间 | 75-100S | 焊接时间 | 小于 3S/点 |

| 波峰接触时间 | 3-5S | NA | NA |

| 锡缸温度 | 260±5℃ | NA | NA |

| 升温斜率 | ≤2℃/S | NA | NA |

| 降温斜率 | ≤6℃/S | NA | NA |

储存条件

模组 MOQ 与包装信息

| 产品型号 | MOQ(pcs) | 出货包装方式 | 每个卷盘存放模组数 | 每箱包装卷盘数 |

|---|---|---|---|---|

| BTU | 4400 | 载带卷盘 | 1100 | 4 |

附录:声明

FCC Caution: Any changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate this device.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Note: This device has been tested and found to comply with the limits for a Class B digital device, according to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This device generates, uses, and can radiate radio frequency energy and, if not installed and used following the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this device does cause harmful interference to radio or television reception, which can be determined by turning the device off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the device and receiver.

- Connect the device to an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Radiation Exposure Statement

This device complies with FCC radiation exposure limits set forth for an uncontrolled rolled environment. This device should be installed and operated with a minimum distance of 20cm between the radiator and your body.

Important Note

This radio module must not be installed to co-locate and operate simultaneously with other radios in the host system except following FCC multi-transmitter product procedures. Additional testing and device authorization may be required to operate simultaneously with other radios.

The availability of some specific channels and/or operational frequency bands are country dependent and are firmware programmed at the factory to match the intended destination. The firmware setting is not accessible by the end-user.

The host product manufacturer is responsible for compliance with any other FCC rules that apply to the host not covered by the modular transmitter grant of certification. The final host product still requires Part 15 Subpart B compliance testing with the modular transmitter installed.

The end-user manual shall include all required regulatory information/warnings as shown in this manual, including “This product must be installed and operated with a minimum distance of 20 cm between the radiator and user body”.

This device has got an FCC ID: 2ANDL-BTU. The end product must be labeled in a visible area with the following: “Contains Transmitter Module FCC ID: 2ANDL-BTU”.

This device is intended only for OEM integrators under the following conditions:

The antenna must be installed such that 20cm is maintained between the antenna and users, and the transmitter module may not be co-located with any other transmitter or antenna.

As long as the 2 conditions above are met, further transmitter tests will not be required. However, the OEM integrator is still responsible for testing their end-product for any additional compliance requirements required with this module installed.

Declaration of Conformity European Notice

Hereby, Hangzhou Tuya Information Technology Co., Ltd declares that this module product is in compliance with essential requirements and other relevant provisions of Directive 2014/53/EU,2011/65/EU. A copy of the Declaration of conformity can be found at https://www.tuya.com.

This product must not be disposed of as normal household waste, in accordance with the EU directive for waste electrical and electronic equipment (WEEE-2012/19/EU). Instead, it should be disposed of by returning it to the point of sale, or to a municipal recycling collection point.

The device could be used with a separation distance of 20cm from the human body.

该内容对您有帮助吗?

是意见反馈该内容对您有帮助吗?

是意见反馈