Solution Introduction

Last Updated on : 2024-06-21 03:56:26download

This topic introduces non-IPC pet feeders.

Solution overview

According to relevant data, in 2019, the number of pet dogs and cats in cities and towns across the country reached 99.15 million, an increase of 8.4%, and the scale of the consumer market reached 202.4 billion yuan, an increase of 18.5% over 2018, showing a sustained and substantial growth overall. The main force of pet owners are young people aged 25 to 38, mostly urban white-collar workers. After satisfying the basic diet of pets, they pay more attention to the scientific feeding and healthy diet of pets.

Tuya provides the leading global Developer Platform that enables consumers, manufacturers, brands, OEMs, and retail chains to develop one-stop AIoT solutions. For pet feeder products, three solutions including hardware access, cloud services, and App software development are currently available to meet consumers’ higher demands for scientific feeding and a healthy diet of pet feeder products.

As one of the most frequently-used solutions to connect to the Tuya Developer Platform, the MCU connection solution is mainly used to enable products with MCU to be smart. It is mainly used to IoT-enable the pet feeder products with MCU master control. It can be connected to the serial port protocol of the Tuya module directly to realize networking. Customers only need to pay attention to the function research and development of the product itself, and the smart part of the network uses the public version of the solution. The specific communication schematic diagram of the MCU solution is as follows:

Document introduction

-

The embedded unit enables the product pairing to upload the data to the cloud, and receives cloud instructions.

-

The IoT module is applied for the ordinary MCU-type feeder and serial communication mode.

-

Wi-Fi SDK development is divided into two solutions: Tuya Standard Module SDK and self-developed module SDK.

-

-

The Tuya Cloud Platform is a globally deployed Developer Platform that connects all devices and apps.

-

The app unit provides various apps for you to remotely control the pet feeder.

-

The all-in-one app is suitable for product quick docking, providing the OEM version with a custom logo.

-

The custom app is suitable for custom products to meet the personalized customization needs of each product.

-

The app SDK is suitable for self-developed apps.

-

-

Voice assistant unit: Third-parties voice assistants including Google Assistant and Amazon Alexa are supported.

-

The operation and maintenance management platform is a platform for you to comprehensively manage product OTA, operation status, active status, and more.

Solution details

Non-IPC pet feeders currently mainly include three types of pet feeders, namely ordinary food box pet feeders, catapult feeding pet feeders, and rotating food box pet feeders.

-

Ordinary feeder box:

There is a food box at the bottom of this type of pet feeder. After the food is put in, the food will be delivered from the food bucket to the food box for pets to eat. Generally, this kind of pet feeder is mainly used for regular feeding, manual feeding, and checking the food. Barrel surplus grain, fault alarm, check feeding record, and other functions.

-

Ejection feeder:

This type of feeder ejects food through an ejection port and can eject one or more grains at a time. It can be combined with voice control equipment to have a stronger interaction with pets.

-

Rotary feeder box:

This type of pet feeder is similar to ordinary food boxes. The difference is that you can match the food ingredients by yourself, instead of the same food every time, all the owner has to do is to configure the food match of the day, and then put it in For food boxes, the device will automatically rotate to open the serving size according to the timing.

Key Features

- Feeding plan:

-

Synchronize to the local device of the device, even if the device is offline, it can still feed and deliver food normally. The feeding plan supports up to 10 feeding plans.

-

RAW format convention: implement local timing according to “period + time + number of servings + switch”, as follows:

- The first 7 bits represent Monday to Sunday, binary to hexadecimal, occupying one byte, 0 means not set, 1 means set, such as 0000001, means Sunday is effective and converted to hexadecimal is 01;

- The time is in the format of hours and minutes, occupying 2 bytes, minutes and hours, from decimal to hexadecimal, such as 18:50, to hexadecimal to 1232;

- The number of servings occupies 1 byte, converts a decimal to hexadecimal, such as 12, converts to hexadecimal to be 0c;

- The switch occupies 1 byte.

00: Disabled.01: Enabled. - In the above example, the result issued by the app terminal time is 0112320c01, which means that on Sunday, 18:50, 12 servings are fed, and it is turned on.

-

- Fast feeding: Fast feeding function. Click to send feeding.

- Manual feeding: Manually select the number of feeding portions.

- Feeding status: The feeding status of the device, including standby, feeding, and feeding completion, etc., supports custom feeding status.

- Unit conversion: Used to switch food units.

- Slow feeding: Enable the switch and turn on the device to perform slow feeding.

- Food disbursement calibration: Click on the disbursement calibration switch and the device will automatically execute it. After the execution is completed, it will automatically close.

- Remaining food calibration: Click to release the surplus grain calibration switch, and it will be executed automatically on the device side. After the execution is completed, it will be closed automatically.

- Restore to factory settings: Restore the device to factory settings.

- Feed disbursement calibration status: Report the disbursement calibration status.

- Battery power: When the device is powered off, it will automatically switch to battery mode, supporting the display of battery power.

- Charging status: charging status display, charging or fully charged.

- Feeding cover status: report the status of the feeding cover, and the APP can display the opening status of the feeding cover.

- Fault alarm: Display default alarm infirmation.

- Feeding results report: Report the feeding results for data statistics.

- Food bucket surplus: Report the remaining percentage of grain bucket surplus.

- Remaining food weight: Report the remaining grain weight and support unit switching.

- Times of voice play: Set the play times, voice call pets to come and eat before each feeding.

- Night light: Night light/indicator switch.

- Switch: It can represent a switch or an automatic ejection switch, which is mainly used for ejection equipment.

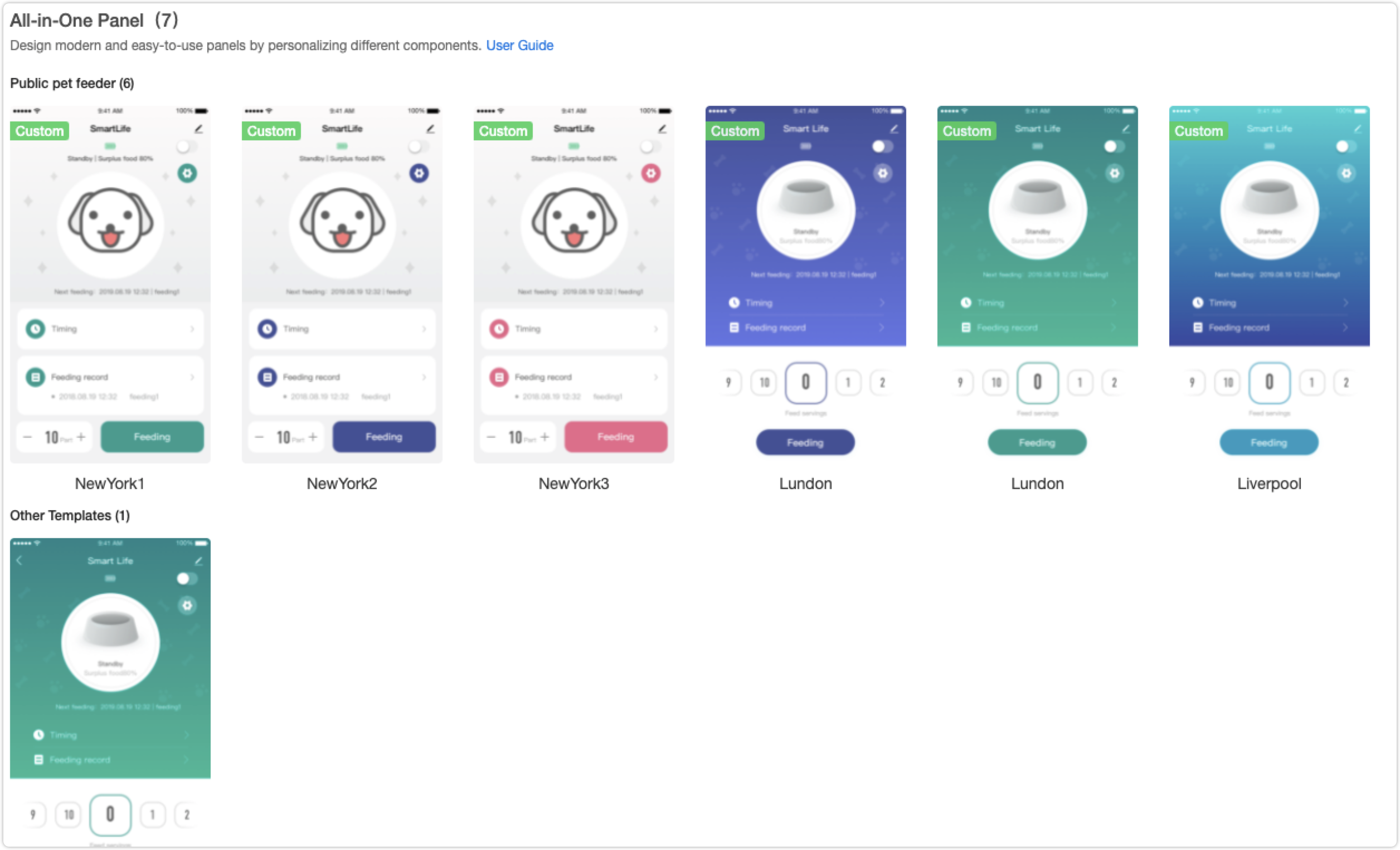

Panel introduction

The pet feeder currently has 2 control panels to choose from, the detailed UI is as follows:

Voice Solution

The voice unit supports the integration with the voice assistants such as Amazon Alexa and Google Assistant.

Module selection

For MCU-type baseboards, WR3 type IoT modules can be provided.

- For more information, see the WBR3 Module Datasheet.

Applied product

Support the access of common food box-type pet feeders, ejection type pet feeders, and rotating food box type pet feeders.

Is this page helpful?

YesFeedbackIs this page helpful?

YesFeedback