PIR Human Sensor

Last Updated on : 2024-06-24 06:02:37download

This topic describes the information about the hardware design for PIR sensors in the application of human sensors.

Overview

The PIR sensor is a pyroelectric infrared sensor that detects changes in infrared rays. It can be used to detect the human body.

Working principle

The human body temperature is generally constant at 37°C, emitting infrared rays with a specific wavelength of about 10 μm. The infrared rays pass through the Fresnel lens and focus on the infrared induction source (pyroelectric component) inside the PIR sensor. The induction source will subject to charge imbalance, and the charge will be released outward. After amplification by the circuit, the level signals will change.

Advantages

With no radiation, low power consumption, and low price.

Disadvantages

- Susceptible to various heat sources and light sources.

- Passive infrared penetration is poor. The infrared radiation of the human body is easily blocked and difficult to be received by the probe.

- Susceptible to radio frequency (RF) radiation.

- When the ambient temperature is close to the human body temperature, the detection sensitivity is significantly reduced, sometimes causing a transient failure.

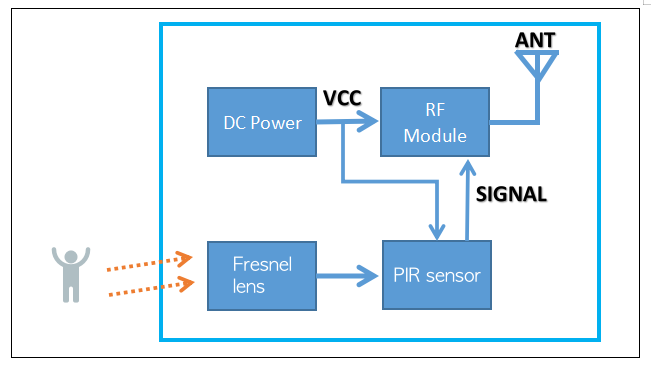

The diagram of the human sensor solution

Fresnel lens

Fresnel lenses are mostly made of polyolefin materials. One side of the lens surface is smooth, and the other side is engraved with concentric circles from small to large.

The texture of the lens is designed according to the requirements of relative sensitivity and receiving angle by using the interference and diffraction of light. It has two functions:

- Focusing is to refract the pyro-infrared signal on the PIR sensor.

- The detection area is divided into a number of bright and dark areas, so that the moving objects entering the detection area can send a changing pyro-infrared signal to the PIR sensor in the form of temperature changes.

The human sensor is mainly used to detect the human body, and its probe aims to detect human body radiation. The internal pyroelectric components need to be very sensitive to infrared radiation with a wavelength of about 10 μm. The addition of a Fresnel lens can effectively concentrate the infrared rays in the detection space on the surface of the pyroelectric component and improve the reliability of detection.

Things to note

- The lens is made of a soft material (polyethylene). A load or impact applied to the lens will cause deformation, resulting in poor operation and performance degradation. Avoid the load or impact.

- Every Fresnel lens has a fixed focal length. Install it with caution since improperly adjusted focal length will decrease the sensitivity of the sensor.

- The color of the lens can inhibit some environmental interference. According to empirical values, ivory white and dark green have better anti-white light and anti-hot wind effects. The principle is that the metal atoms and molecules of inorganic salts in these pigments can absorb the white light of 6,500 lux to prevent the white light from entering the probe.

- The thickness of the lens has little effect on anti-white light and anti-hot wind effects, but it affects the sensitivity. The smaller the thickness is, the higher the light transmittance will be, and the more sensitive the device will be.

- When you select a lens, first determine the application scenario, height, inclination, and more. Then, determine the size, focal length, and shape of the optical area that can be provided. Lastly, determine the sensing angle requirements, distance requirements, and more.

- When the lens is used with a PIR sensor, the sensing distance parameter must be derated. For example, when the designed sensing distance of the PIR sensor is d, the sensing distance parameter of the lens must be 1.2*d.

- The surface texture of the lens can be classified into isobathymetric type and equidistant type. The isobathymetric texture is more conducive to the flatness of the flat lens. The equidistant texture can be divided by thickness; if it is too thin, the light loss will be huge.

- Lenses can be divided into three types: horizontal curtain type, vertical curtain type, and spherical type.

- The horizontal curtain lens has a large sensing angle, which can avoid interference from upper and lower infrared rays. Therefore, it is suitable for wall mounting.

- The vertical curtain lens has a small sensing angle, which can avoid interference from the left and right infrared rays. Therefore, it is suitable for wall mounting.

- The spherical lens is suitable for ceiling mounting and is used for large-area detection.

- Since the lens directly affects the performance of the sensor, it is recommended to find a professional Fresnel lens design manufacturer in the early ID design stage.

The design of the PIR sensor

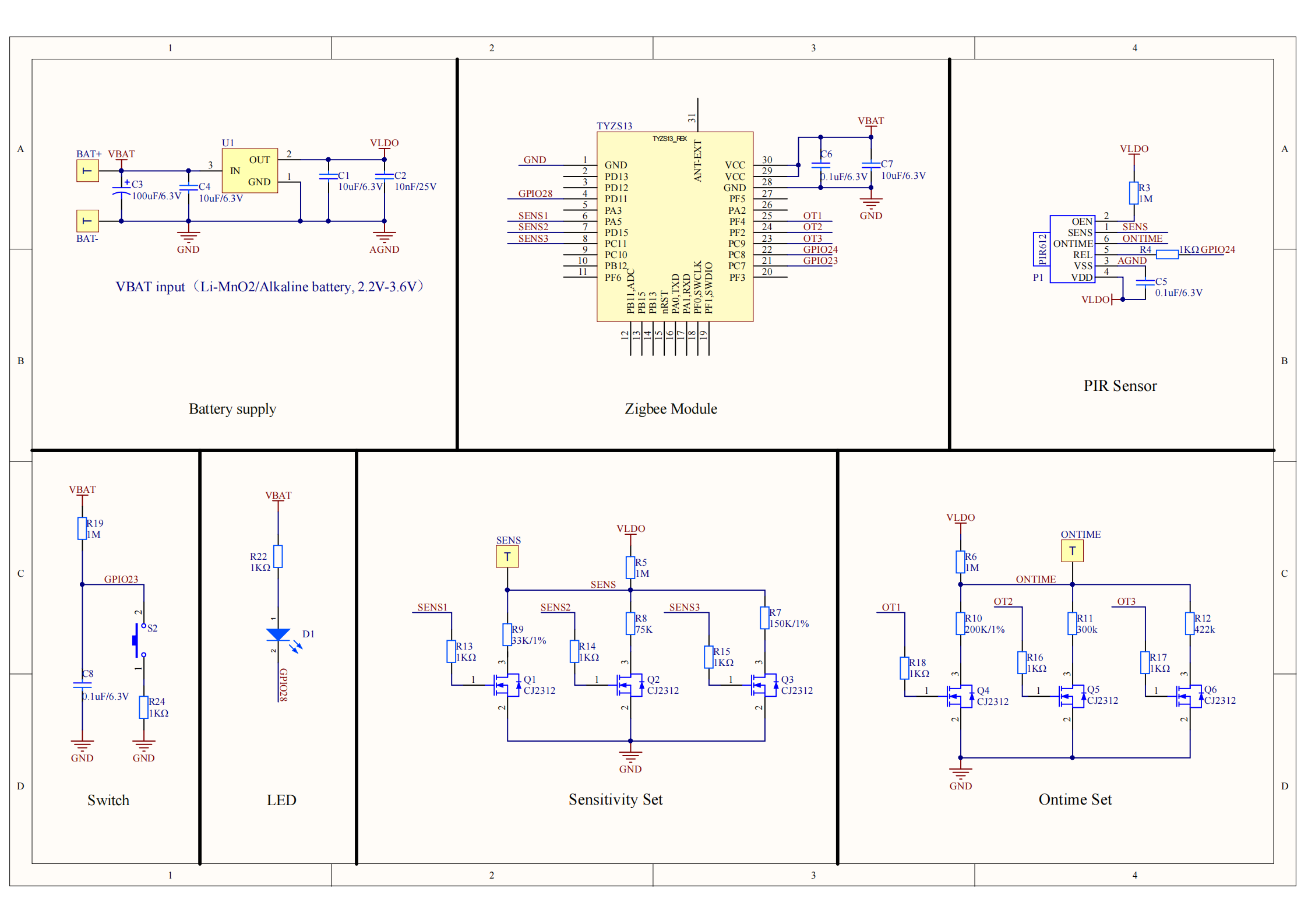

The schematic diagram above is a typical application diagram of the PIR human sensor based on Zigbee wireless communication. The solution supports battery power supply, sensor sensitivity setting, and trigger duration setting.

Things to note for designing

- For the PIR human sensor developed based on the network module, at least one button and one indicator must be reserved for modifying and indicating the network status of the sensor.

- If a PCB antenna is used for the wireless module, the PCB area of the PCB antenna needs to be hollowed out to ensure antenna performance.

- When designing the PCB, keep the antenna of the module as far away as possible from the body of the sensor to prevent radio frequency radiation from affecting the normal operation of the sensor.

- The wiring between the PIR sensor and other components must be as short as possible. Avoid wiring under the wires on the double-sided or multi-layer board, especially high-current wirings.

- The circuit of the sensing part of the PIR sensor should be isolated and have a separate ground terminal, and can be connected to the ground through a 0R resistor.

- The power pin of the PIR sensor needs to be connected to the ground with a 100 nF capacitor, and the capacitor must be placed close to the power pin.

- The detection of the PIR sensor is directional, and the sensitivity is the highest when moving horizontally along the long side. Pay attention to the placement direction of the sensor when designing the PCB.

Things to note for debugging

- When cleaning the board, avoid cleaning the PIR sensor. Otherwise, the cleaning fluid invades the interior and may cause performance degradation.

- When hand-soldering the PIR sensor, keep the temperature of the electric soldering iron below 350°C and finish soldering in three seconds. Over-time soldering may cause performance degradation.

- If static electricity beyond the range of ±200V is applied, the sensor might be damaged. Therefore, be careful during operation and avoid touching the terminals directly with your hands.

- Due to the working principle and attributes of the PIR sensor, the PIR sensor is susceptible to temperature and airflow. The probe needs to be used with a Fresnel lens and adapted in structure.

- When there is dirt on the sensor window, the detection performance will be affected.

- Every Fresnel lens has a fixed focal length. Install it with caution since improperly adjusted focal length will decrease the sensitivity of the sensor.

Is this page helpful?

YesFeedbackIs this page helpful?

YesFeedback