TCS600U Series Hardware Design Guidelines

Last Updated on : 2024-06-18 01:56:56download

These guidelines are intended to serve as a reference when you develop with TCS600U modules. It helps you get an overall understanding of the product specifications and assists in developing IoT products and applications.

Background

Glossary

| Abbreviation | Spelled-out |

|---|---|

| ESD | Electrostatic discharge |

| USB | Universal serial bus |

| UART | Universal asynchronous receiver-transmitter |

| SIM | Subscriber identification module |

| SPI | Serial peripheral interface |

| I2C | Inter-integrated circuit |

| I/O | Input/Output |

| GPIO | General-purpose input/output |

| TBD | To be determined |

| RTC | Real time clock |

| ADC | Analog-to-digital converter |

Reference

- TCS600U Datasheet

- TCS600U Hardware Design Guidelines (This documentation)

- TCS600U Schematic Diagram

- TCS600U Open CPU GPIO Configuration

- LTE Cat.1 Serial Protocol

- LTE Cat.1 Open CPU Development

Product overview

TCS600U is an LTE Cat.1 cellular module developed by Tuya Smart. The TCS600U module consists of a highly integrated LTE Cat.1 chip UIS8910DM and peripheral circuits. It has a built-in LTE Cat.1 network communication protocol stack and library functions.

The TCS600U module is built around an Arm Cortex-A5 processor and Cat.1 bis modem and embedded with 64 MB NOR flash and 128 MB PSRAM. It provides a wide array of interfaces including USB, UART, SDIO, SPI, I2C, I2S, and ADC for supporting peripherals such as the display, camera, microphone, speaker, microSD card, and USIM card.

Models

| Model | TCS600U |

|---|---|

| LTE FDD | Band 1, 3, 5, 8 |

| LTE TDD | Band 34, 38, 39, 40, 41 |

| VoLTE | Support |

| GNSS | Not supported |

| Bluetooth Low Energy 4.2 | Not supported |

| Wi-Fi Scan | Not supported |

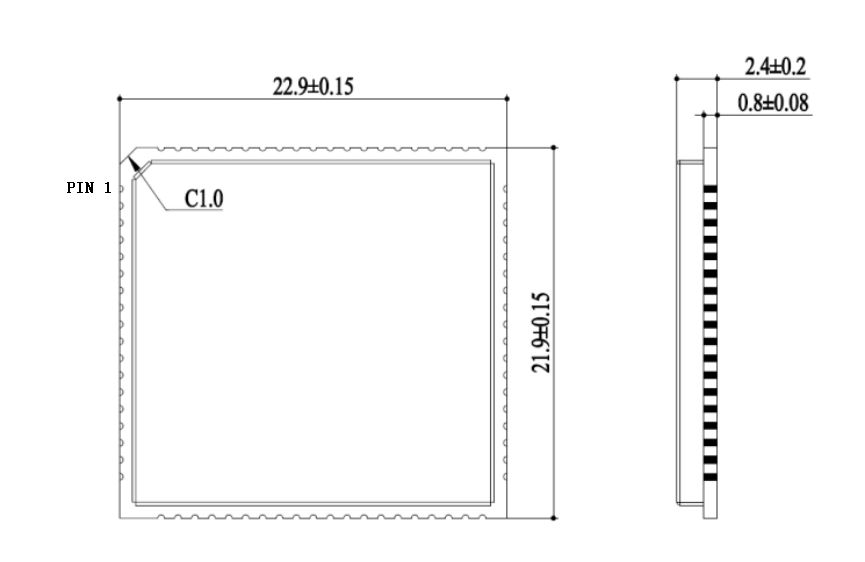

| Dimensions | 21.9 mm × 22.9 mm |

Features

| Features | Description |

|---|---|

| Processor | Arm Cortex-A5 500 MHz microprocessor |

| Voltage |

|

| LTE Cat.1 speed |

|

| Interfaces |

|

| USB |

|

| UART interfaces |

|

| USIM card | 1.8V and 3V supported |

| Display | SPI display in 320 × 240 pixel resolution at 30 fps |

| Camera | Support SPI/MIPI camera, up to 640 × 480 pixel resolution. The I/O interface supports 1.8V only. |

| Audio |

|

| MicroSD card | Support |

| Antenna interface | LTE antenna with 50Ω characteristic impedance. |

| Operating temperature |

|

| Integration solutions |

|

| Software updates | USB update or OTA update |

| Package |

|

- 1 Within the operation temperature range, the module is 3GPP compliant.

- 2 Within the extended temperature range, the module remains the ability to operate properly. Only the values of one or more parameters like output power might exceed the specified tolerances of 3GPP specifications.

Pin configuration and functions

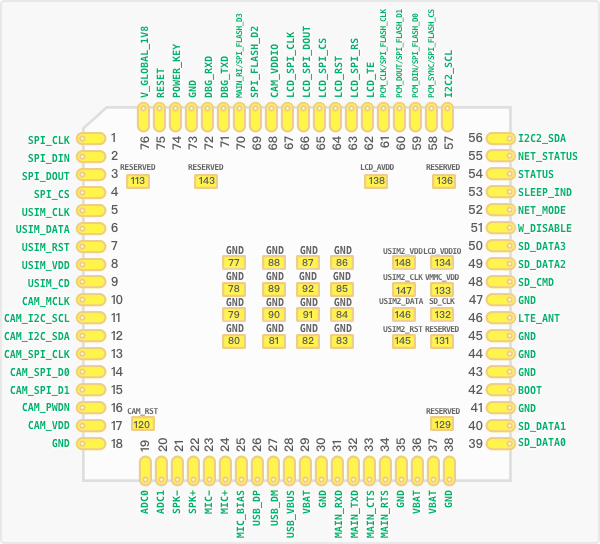

TCS600U is equipped with a total of 106 pins, including 76 LCC pins and 30 LGA pins.

The pinout is as follows:

I/O parameters definition

| Type | Description |

|---|---|

| IO | Input/Output |

| DI | Digital input |

| DO | Digital output |

| PI | Power input |

| PO | Power output |

| AI | Analog input |

| AO | Analog output |

| OD | Open drain output |

Pin description

| Pin No. | Pin name | I/O type | Description |

|---|---|---|---|

| 1 | SPI_CLK | DO | SPI1 clock signal output. It can be used as GPIO93 in OpenCPU mode. |

| 2 | SPI_DIN | DI | SPI1 data input. It can be used as GPIO12 in OpenCPU mode. |

| 3 | SPI_DOUT | DO | SPI1 data output. It can be used as GPIO11 in OpenCPU mode. |

| 4 | SPI_CS | DO | SPI1 chip select signal. It can be used as GPIO10 in OpenCPU mode. |

| 5 | USIM_CLK | DO | USIM card clock signal. |

| 6 | USIM_DATA | IO | USIM card data signal. |

| 7 | USIM_RST | DO | USIM card reset signal. |

| 8 | USIM_VDD | PO | Power supply for USIM card. Either 1.8V or 3.0V is supported by the module automatically. IOMAX = 50 mA. |

| 9 | USIM_CD | DI | USIM card hot-plug detection, which is disabled by default in the software. Pull this pin up to V_GLOBAL_1V8. |

| 10 | CAM_MCLK | DO | Camera MCLK output. |

| 11 | CAM_I2C_SCL | IO | Camera I2C clock signal, which can also be used as a general-purpose I2C interface. |

| 12 | CAM_I2C_SDA | IO | Camera I2C data signal. It can also be used as a general-purpose I2C interface or as GPIO17 in OpenCPU mode. |

| 13 | CAM_SPI_CLK | DI | Camera SPI clock input. |

| 14 | CAM_SPI_D0 | DI | Camera SPI data input 0. |

| 15 | CAM_SPI_D1 | DI | Camera SPI data input 1. |

| 16 | CAM_PWDN | DO | Camera power down. |

| 17 | CAM_VDD | PO | Analog power supply for camera, with voltage ranging from 1.6V to 3.2V, and defaulting to 1.8V. IOMAX = 100 mA. By default, the analog power is down after the module is powered on. |

| 18 | GND | - | Ground |

| 19 | ADC0 | AI | Analog-to-digital converter (ADC). Input voltage: 0 to VBAT Channel: 0 Resolution: 11 Bits |

| 20 | ADC1 | AI | Analog-to-digital converter (ADC). Input voltage: 0 to VBAT Channel: 1 Resolution: 11 Bits |

| 21 | SPK- | AO | Negative audio differential output, with no built-in power amplifier. It can drive a 32Ω receiver. An external power amplifier is required to connect to an 8Ω external speaker. |

| 22 | SPK+ | AO | Positive audio differential output, with no built-in power amplifier. It can drive a 32Ω receiver. An external power amplifier is required to connect to an 8Ω external speaker. |

| 23 | MIC- | AI | Negative microphone input signal. |

| 24 | MIC+ | AI | Positive microphone input signal. |

| 25 | MIC_BIAS | PO | Microphone bias voltage. |

| 26 | USB_DP | IO | Positive USB differential signal, which should have a 90Ω differential impedance. |

| 27 | USB_DM | IO | Negative USB differential signal, which should have a 90Ω differential impedance. |

| 28 | USB_VBUS | DI | Used to detect USB port insertion. Input voltage: 3.3V to 5.25V Vnorm = 5.0V Insertion of a USB device will charge and start up the module. As a result, the module cannot be shut down in this state. |

| 29 | VBAT | PI | Power supply for module. Supply voltage: 3.4V to 4.3V. Nominal voltage: 3.8V. The external power supply should output 2A. It is recommended to add a surge protector. |

| 30 | GND | - | Ground |

| 31 | MAIN_RXD | DI | The UART1 receives data. |

| 32 | MAIN_TXD | DO | The UART1 sends data. |

| 33 | MAIN_CTS | DO | DTE UART1 clear to send, connected to DTE’s CTS. It can be used as GPIO19 in OpenCPU mode. |

| 34 | MAIN_RTS | DI | DTE UART1 request to send, connected to DTE’s RTS. It can be used as GPIO18 in OpenCPU mode. |

| 35 | GND | - | Ground |

| 36 | VBAT | PI | Power supply for module. Supply voltage: 3.4V to 4.3V. Nominal voltage: 3.8V. The external power supply should output 2A. It is recommended to add a surge protector. |

| 37 | VBAT | PI | Power supply for module. Supply voltage: 3.4V to 4.3V. Nominal voltage: 3.8V. The external power supply should output 2A. It is recommended to add a surge protector. |

| 38 | GND | - | Ground |

| 39 | MAIN_DTR/SD_DATA0 | DI/IO | Wake-up control, or SDIO data bit 0. |

| 40 | MAIN_RI/SD_DATA1 | DO/IO | Main UART ring indicator, or SDIO data bit 1. |

| 41 | GND | - | Ground |

| 42 | BOOT | DI | Short this pin to V_GLOBAL_1V8 on startup will make the module enter download mode. Leaving this pin floating will start the module in normal mode. |

| 43 | GND | - | Ground |

| 44 | GND | - | Ground |

| 45 | GND | - | Ground |

| 46 | LTE_ANT | AIO | LTE antenna output, with 50Ω characteristic impedance. |

| 47 | GND | - | Ground |

| 48 | MAIN_DCD*/SD_CMD | DO/IO | Main UART data carrier detect, or SDIO signals. |

| 49 | WAKEUP_IN*/SD_DATA2 | DI/IO | Wake-up control, or SDIO data bit 2. |

| 50 | AP_READY*/SD_DATA3 | DI/IO | Detecting the sleep mode for application processor, or SDIO data bit 3. |

| 51 | W_DISABLE* | DI | Used to force the module into airplane mode. It can be used as GPIO22 in OpenCPU mode. |

| 52 | NET_MODE* | DO | Indicate the registered mobile network standard. |

| 53 | SLEEP_IND* | DO | Indicating the sleep mode, or UART2_TXD. It can be used as GPIO21 in OpenCPU mode. |

| 54 | STATUS* | DO | Indicating the module’s operating status, or UART2_RXD. It can be used as GPIO20 in OpenCPU mode. |

| 55 | NET_STATUS | DO | Indicate the module’s network registration mode, which applies when the module operates in self-processing mode. |

| 56 | I2C2_SDA | IO | I2C2 data signal. It can be used as GPIO15 in OpenCPU mode. |

| 57 | I2C2_SCL | IO | I2C2 clock signal. It can be used as GPIO14 in OpenCPU mode. |

| 58 | PCM_SYNC/SPI_FLASH_CS | DO | PCM data sync, or SPI_FLASH_CS. |

| 59 | PCM_DIN/SPI_FLASH_D0 | DI/IO | PCM data input, or SPI_FLASH_D0. |

| 60 | PCM_DOUT/SPI_FLASH_D1 | DO/IO | PCM data output, or SPI_FLASH_D1. |

| 61 | PCM_CLK/SPI_FLASH_CLK | DO | PCM audio clock signal, or SPI_FLASH_CLK. |

| 62 | LCD_TE | DO | LCD SPI frame sync signal |

| 63 | LCD_SPI_RS | DO | LCD SPI register select signal. |

| 64 | LCD_RST | DO | LCD SPI reset signal |

| 65 | LCD_SPI_CS | DO | LCD SPI chip select signal. |

| 66 | LCD_SPI_DOUT | DO | LCD SPI data signal. |

| 67 | LCD_SPI_CLK | DO | LCD SPI clock signal. |

| 68 | CAM_VDDIO | PO | Digital power supply for camera, with voltage ranging from 1.4V to 2.1V, and defaulting to 1.8V. IOMAX = 100 mA. By default, the digital power is down after the device is powered on. |

| 69 | I2C3_SDA/SPI_FLASH_D2 | IO | I2C3 data signal, or SPI_FLASH_D2. |

| 70 | I2C3_SCL/SPI_FLASH_D3 | IO | I2C3 clock signal, or SPI_FLASH_D3. It can be used as GPIO5 in OpenCPU mode. |

| 71 | DBG_TXD | DO | Debugging interface, used to output AP logs. |

| 72 | DBG_RXD | DI | Debugging interface, used to receive commands. |

| 73 | GND | - | Ground |

| 74 | POWER_KEY | DI | Control module power on/off, with an internal pull-up to VBAT. |

| 75 | RESET | DI | Reset module, active low, with an internal pull-up to VBAT. |

| 76 | V_GLOBAL_1V8 | PO | Provide fixed 1.8V output. IOMAX = 50 mA. This pin is automatically enabled upon startup and cannot be disabled. It can be used as pull-up power for peripherals. |

| 77 to 92 | GND | - | Ground |

| 113 | RESERVED | - | Reserved pin |

| 120 | CAM_RST | DO | Camera reset signal. |

| 129 | RESERVED | - | Reserved pin |

| 131 | RESERVED | - | Reserved pin |

| 132 | SD_CLK | DO | SDIO clock signal. |

| 133 | VMMC_VDD | PO | Power supply for SDIO, defaulting to 3.1V. IOMAX = 150 mA. |

| 134 | LCD_VDDIO | PO | Digital power supply for LCD, defaulting to 1.8V. IOMAX = 200 mA. |

| 136 | RESERVED | - | Reserved pin |

| 138 | LCD_AVDD | PO | Analog power supply for LCD, defaulting to 3.0V. IOMAX = 150 mA. |

| 143 | RESERVED | - | Reserved pin |

| 145 | USIM2_RST | DO | USIM2 reset signal. |

| 146 | USIM2_DATA4 | IO | USIM2 data signal. |

| 147 | USIM2_CLK4 | DO | USIM2 clock signal. |

| 148 | USIM2_VDD4 | PO | Power supply for USIM2 card. Either 1.8V or 3.0V is supported by the module automatically. IOMAX = 50 mA. |

*indicates a feature cannot be implemented with MCU integration, but it can be implemented through GPIO configuration in OpenCPU mode.- 3: With OpenCPU SDK based firmware, you can configure this GPIO pin as you wish.

- 4: Dual SIM is not supported currently. If you require a dual SIM application, contact the product manager for customization.

Power supply

Power and ground pins

TCS600U can be powered by a battery or an external power supply. The ground pin and signal ground pin must be connected to the ground plane on the PCB. Otherwise, the overall performance of the module might be affected.

| Pin No. | Pin name | Description | Min | Typical | Max | Unit |

|---|---|---|---|---|---|---|

| 29, 36, 37 | VBAT | Module power input. | 3.4 | 3.8 | 4.3 | V |

| 18, 30, 35, 38, 41, 43, 44, 45, 47, 73, 77 to 92 | GND | GND | - | - | - | - |

Power supply requirements

-

The supply voltage of the TCS600U module ranges from 3.4V to 4.3V, with a peak current of 2A.

- If the difference between the input and output voltage is small, you can use a low-dropout (LDO) regulator to maintain the required system voltage.

- If the difference between the input and output voltage is large, you can use a DC-to-DC converter to regulate the output voltage.

-

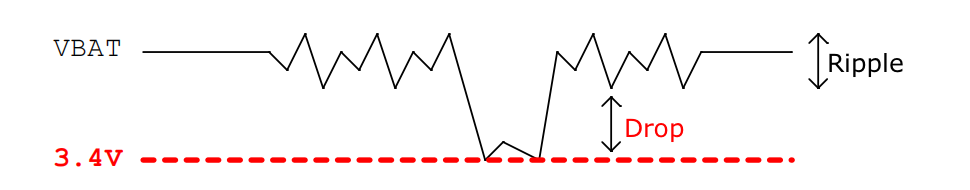

Voltage drop: When the module is working, make sure its input voltage will never drop below 3.4V and the ripple voltage is less than 300 mV.

-

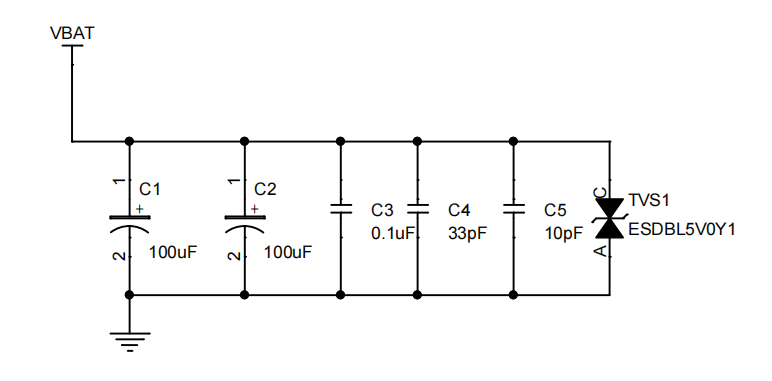

Voltage regulator and filter capacitor:

- Capacitors used for the voltage regulation circuit of a power supply: 100 μF × 2 (equivalent series resistance = 0.7Ω)

- Filter capacitors: 0.1 μF, 33 pF, and 10 pF

-

Electrostatic discharge protection: Add a TVS diode near the

VBATinput pin to improve surge voltage withstand capability. -

In principle, star routing topology is required. The longer the

VBATtrace is, the wider it should be. -

If the module is powered by a battery, you can enable low voltage (less than 3.38V) shutdown, with consideration of the power of other components on the backplane. Otherwise, the module might not be powered on due to battery over-discharge.

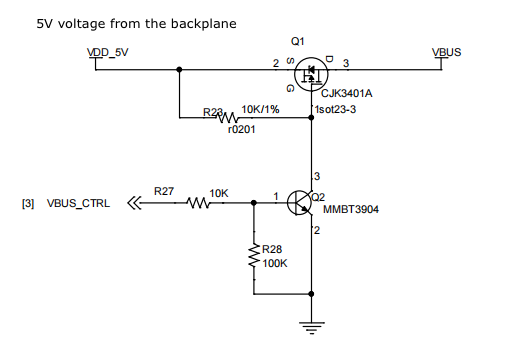

-

A reference circuit is illustrated in the following figure.

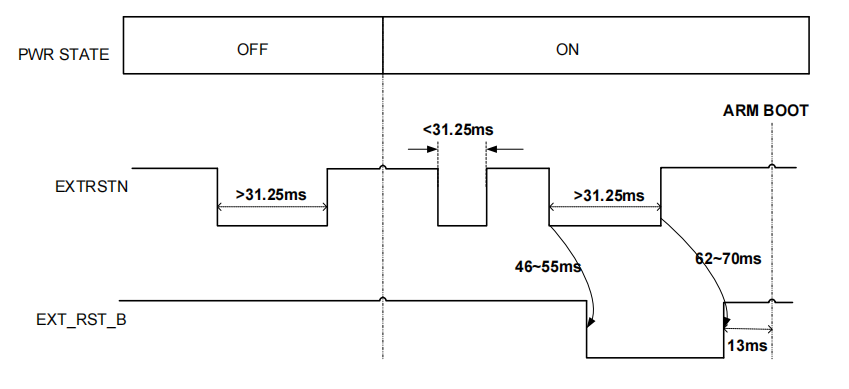

Power on/off and reset

Pin description

| Pin No. | Pin name | Description |

|---|---|---|

| 74 | POWER_KEY | Control module power on/off, with an internal pull-up to VBAT. |

| 75 | RESET | Reset module, active low, with an internal pull-up to VBAT. |

Applications

-

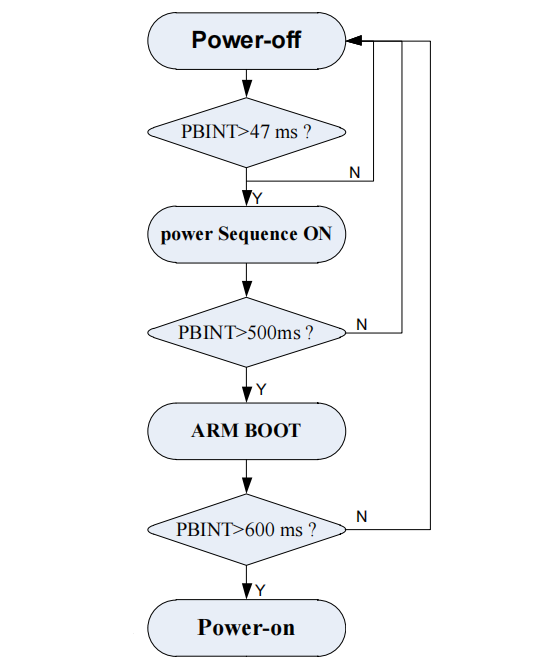

Power on: Pull down

POWER_KEYfor at least 1.5 seconds. The module will start up. If theVBATvoltage exceeds the startup voltage of 3.3V, the module will continue booting until the process is completed. Otherwise, the module will shut down. After the module starts up,POWER_KEYcan be released. You can detect the voltage onV_GLOBAL_1V8to determine whether startup is completed.

-

Auto power-on: If you want the module to be powered on whenever a power source is connected and do not need the shutdown feature, you can pull down

POWER_KEYto ground. -

Reset: The module will be reset after the

RESETpin is driven to a low level for at least 35 ms and then pulled up or left floating.

-

Power off: In power-on state, pull down

POWER_KEYfor at least 1.5 seconds, and the module will shut down. -

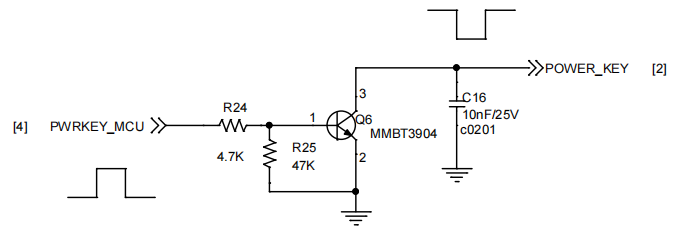

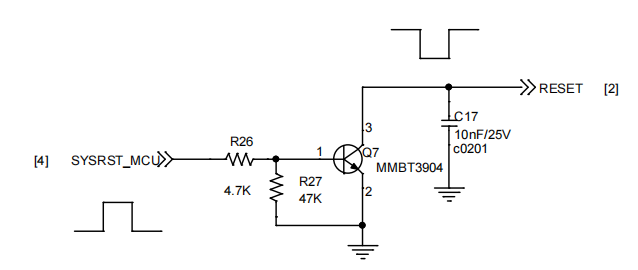

An open collector is recommended to control the module’s pin, as shown in the following schematics.

-

Power-on circuit

-

Reset circuit

-

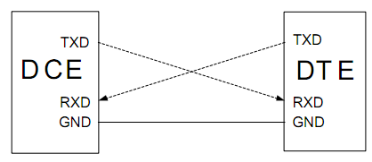

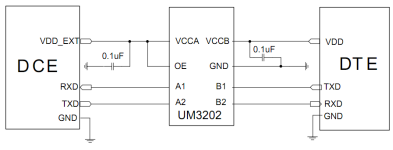

UART

Pin description

The module provides four UART interfaces:

-

UART 1: used to interface with your MCU through AT commands or Tuya’s serial communication protocol. The baud rate is 115200 bps by default.

-

UART 2: used to connect to peripheral devices.

-

Debug interface: used to receive debugging commands and output AP logs. It is recommended to reserve test points during the development stage.

-

ZSP interface: used to output CP logs.

Pin No. Pin name Description 32 MAIN_TXD UART 1 receives data. Auto-baud mode can detect 9600 bps and 115200 bps. 31 MAIN_RXD UART 1 sends data. Auto-baud mode can detect 9600 bps and 115200 bps. 33 MAIN_CTS DTE UART 1 clear to send. 34 MAIN_RTS DTE UART 1 request to send. 54 SLEEP_IND Reused as UART2_TXDto send data.53 STATUS Reused as UART2_RXDto receive data.71 DBG_TXD Debugging interface, used to output AP logs. 72 DBG_RXD Debugging interface, used to receive commands. 51 W_DISABLE Reused as ZSP_UART_TXDto output CP logs.

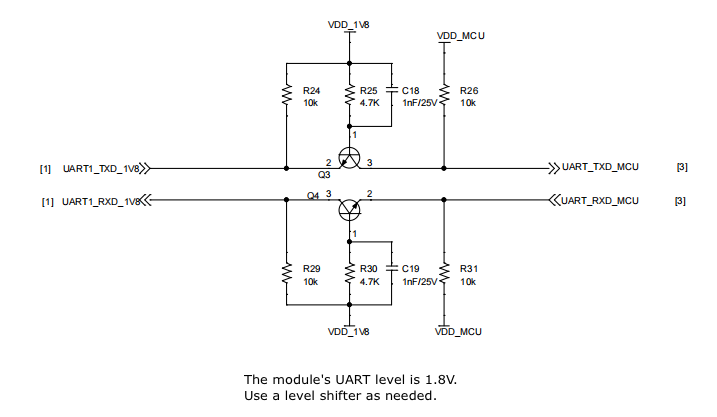

Applications

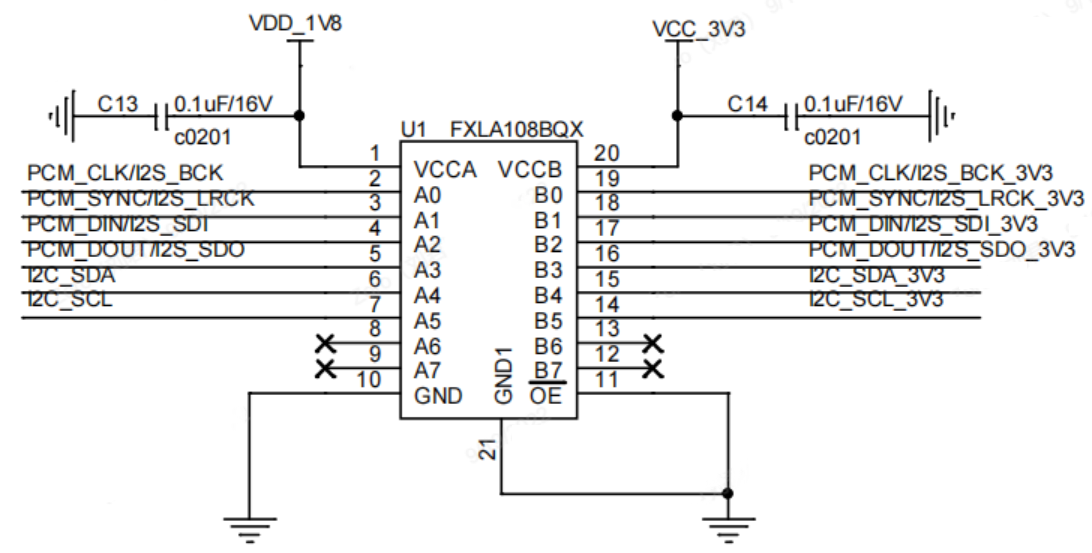

The module provides 1.8V UART interfaces. A level translator should be used if the application is equipped with a 3.3V or 5V UART interface.

Alternatively, use a triode to translate voltage levels.

See the circuit diagram above for how UART 1 and UART 2 are connected.

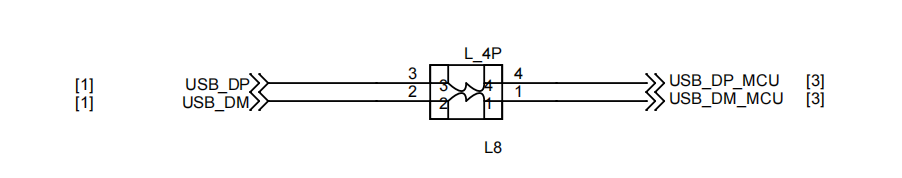

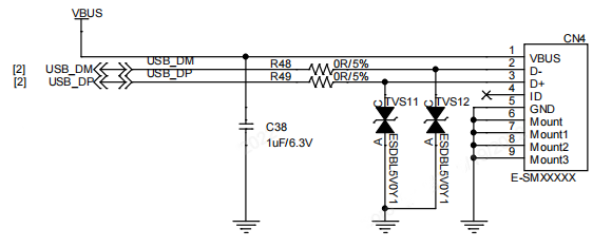

USB

Pin description

The USB interface conforms to USB 2.0 specifications with a maximum data transfer speed of 480 Mbps and can be used to download code to the module and send AT commands.

For all your projects, it is strongly recommended to reserve a USB port for program download and debugging.

| Pin No. | Pin name | Description |

|---|---|---|

| 28 | USB_VBUS | Used to detect USB port insertion. Input voltage: 3.3V to 5.25V Vnorm = 5.0V Insertion of a USB device will charge and start up the module. As a result, the module cannot be turned off in this state. |

| 26 | USB_DP | USB high-speed differential transceiver (positive). It can be used to download code to the module. |

| 27 | USB_DM | USB high-speed differential transceiver (negative). It can be used to download code to the module. |

| 42 | USBBOOT | Pulling up this pin to V_GLOBAL_1V8 before power-on will enable the module to enter USB download mode. |

Applications

-

MCU solutions

-

Micro-USB cable

Circuit design

-

Pull up

USBBOOTtoVDD_EXTto make the module enter USB download mode. -

Route the USB signal traces as parallel differential pairs with equal lengths.

-

The trace impedance of the USB differential pair should be 90Ω.

-

Do not route signal traces under the power supply, RF signal traces, and other sensitive signal traces. It is important to route the USB differential traces in the inner layer with ground shielding on not only the upper and lower layers but also the right and left sides.

-

Connect a common mode choke between the MCU and module in series to improve EMI suppression.

-

VBUSis used to detect the presence of the USB bus. If the USB port on your MCU does not support the suspend mode, you can disconnectVBUSto make the module enter sleep mode.

-

Considering connection to micro-USB devices, place the TVS diode as close to the USB port as possible with a parasitic capacitance of less than 2 pF.

Download and debug

-

When the MCU communicates with the module through the USB port, it is recommended to use zero-ohm resistors to reserve a test point or micro-USB port for firmware updates and debugging. Zero-ohm resistors should be adopted with a pad-sharing design.

-

Before the module starts up, pull up

USB_BOOTtoV_GLOBAL_1V8to start the module in download mode. -

It is recommended to reserve

USB_BOOTandV_GLOBAL_1V8as test points for downloading and debugging. -

After the module enters the download mode, the port will be displayed in the Device Manager on your computer.

USIM card

Pin description

The module provides two SIM card interfaces:

| Pin No. | Pin name | Description |

|---|---|---|

| 5 | USIM_CLK | USIM card clock signal. |

| 6 | USIM_DATA | USIM card data signal. |

| 7 | USIM_RST | USIM card reset signal. |

| 8 | USIM_VDD | Power supply for USIM card. Either 1.8V or 3.0V is supported by the module automatically. |

| 9 | USIM_CD | USIM card insertion detection. If it is unused, pull it up to VDD_EXT. |

| 145 | USIM2_RST* | USIM2 reset signal. It can be used as GPIO31 in OpenCPU mode. |

| 146 | USIM2_DATA* | USIM2 data signal. It can be used as GPIO30 in OpenCPU mode. |

| 147 | USIM2_CLK* | USIM2 clock signal. It can be used as GPIO29 in OpenCPU mode. |

| 148 | USIM2_VDD* | Power supply for USIM2 card. Either 1.8V or 3.0V is supported by the module automatically. IOMAX = 50 mA. |

*: Currently, the OpenCPU SDK does not support USIM2 card. You can use related pins as GPIO.

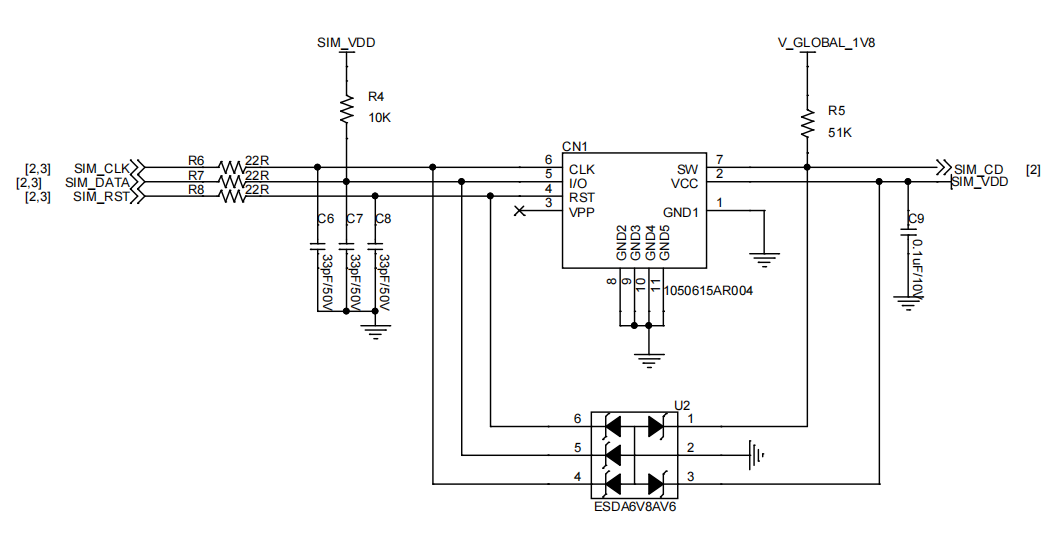

Applications

Circuit design

- Place the USIM card connector near the module. Keep the trace length as less than 200 mm as possible.

- Place a 100 nF filter capacitor between

USIM_VDDand GND, close to the card connector. - Place a 10 to 20K pull-up resistor on the

USIM_DATAto reduce EMI. - Place the RF bypass capacitors (33 pF) close to the USIM card connector on all signal traces (

USIM_DATA,USIM_RST, andUSIM_CLK) to reduce RF interference. - Keep the USIM card signal traces away from

RFandVBATtraces. To avoid crosstalk betweenUSIM_CLKandUSIM_DATA, keep them away from each other. - In order to offer good ESD protection, it is recommended to add a TVS diode array with a parasitic capacitance of less than 15 pF. The ESD protection device should be placed as close to the SIM card connector as possible, and make sure the SIM card signal lines go through the ESD protection device first and then to the module.

- For the design of USIM card hot-plug, the

USIM_CDis shorted to the ground when no card is inserted. When a card is inserted,USIM_CDfloats and is pulled up byV_GLOBAL_1V8. If you do not use hot-plug USIM card connectors, keepUSIM_CDfloating.

SD card

Pin description

The module provides one SD 2.0 interface. GPIO pins are reused to enable access to memory cards compliant with SD 2.0 and SDIO 1.1 standards.

| Pin No. | Pin name | I/O type | Power supply domain | Description |

|---|---|---|---|---|

| 132 | SD_CLK | DO | SD card SDIO clock signal. | |

| 48 | MAIN_DCD/SD_CMD | IO | VMMC | SD card SDIO command signal. |

| 39 | MAIN_DTR/SD_DATA0 | IO | VMMC | SD card SDIO data bit 0. |

| 40 | MAIN_RI/SD_DATA1 | IO | VMMC | SD card SDIO data bit 1. |

| 49 | WAKEUP_IN/SD_DATA2 | IO | VMMC | SD card SDIO data bit 2. |

| 50 | AP_READY/SD_DATA3 | IO | VMMC | SD card SDIO data bit 3. |

| 133 | VMMC_VDD | PO | SD card SDIO bus pull-up power. |

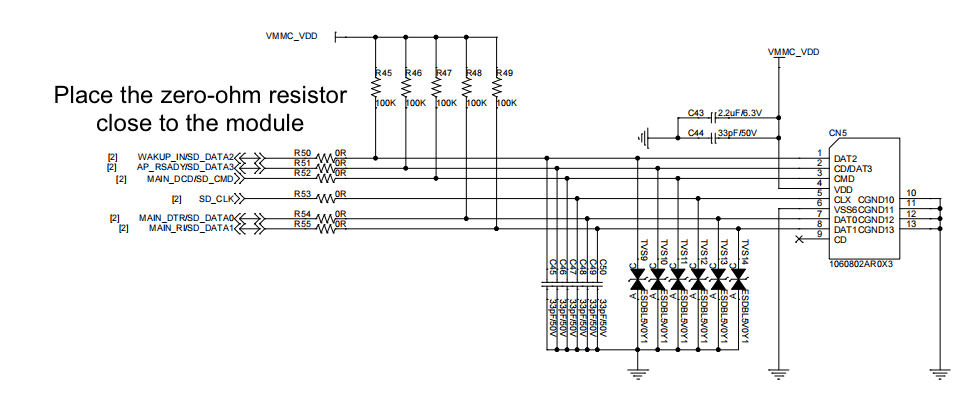

Applications

Circuit design

- The maximum output current of

VMMC_VDDis 150 mA. If the current consumption of the SD card exceeds 150 mA, an external power supply is needed. - Connect a 22Ω resistor between the

SD_CLKand SD signal trace in series to reduce RF interference. - Reserve a pad for 33 pF capacitor on the signal trace to reduce RF interference.

- Reserve a pad for a pull-up resistor (100 kΩ is recommended) on the SD signal trace for increasing the stability of the bus line.

VMMC_VDDis the pull-up power supply. SD_CLKneeds ground shielding. Surround SD signal traces with total grounding to prevent any possible crosstalk and noise coupling from other signal sources.- It is recommended to keep the same trace length for

SD_CLK,SD_DATA[0:3], andSD_CMD, with a length difference of less than 1 mm. The total length should not exceed 50 mm. - In order to offer good ESD protection, it is recommended to add a TVS diode array with a parasitic capacitance of less than 15 pF. The ESD protection device should be placed as close to the SIM card connector as possible, and make sure the SIM card signal lines go through the ESD protection device first and then to the module.

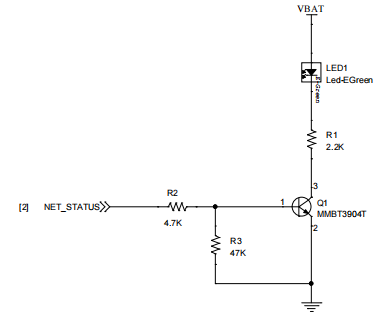

Network status indication

Description of the NET_STATUS interface.

| Pin No. | Pin name | Description |

|---|---|---|

| 52 | NET_MODE* | The mobile network standard. |

| 55 | NET_STATUS | Indicate the network status, which applies when the module operates in self-processing mode. |

*: TCS600U only supports LTE mode, so there is no need to differentiate between network modes. NET_MODE can be used as a GPIO.

Applications

SPI interface

Pin description

| Pin No. | Pin name | I/O type | Power supply domain | Description |

|---|---|---|---|---|

| 1 | SPI_CLK | DO | V_PAD_1V8_RTC | SPI1 clock signal output |

| 2 | SPI_DIN | DI | V_PAD_1V8_RTC | SPI1 data input |

| 3 | SPI_DOUT | DO | V_PAD_1V8_RTC | SPI1 data output |

| 4 | SPI_CS | DO | V_PAD_1V8_RTC | SPI1 chip select signal |

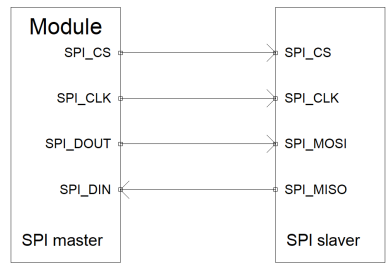

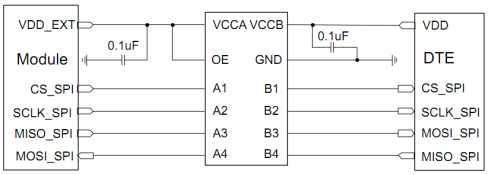

Applications

The SPI on TCS600U only supports the controller mode.

The voltage of the SPI interface is 1.8V. Therefore, a level translator between the module and MCU should be used if the system voltage of the MCU is 3.3V.

A reference circuit is illustrated in the following figure.

I2C bus

Pin description

The module provides three I2C interfaces.

| Pin No. | Pin name | I/O type | Power supply domain | Description |

|---|---|---|---|---|

| 11 | CAM_I2C_SCL | IO | V_PAD_1V8 | Camera I2C clock signal |

| 12 | CAM_I2C_SDA | IO | V_PAD_1V8 | Camera I2C data signal |

| 56 | I2C2_SDA | IO | V_PAD_1V8 | I2C2 data signal |

| 57 | I2C2_SCL | IO | V_PAD_1V8 | I2C2 clock signal |

| 69 | I2C3_SDA | IO | V_PAD_1V8 | I2C3 data signal |

| 70 | I2C3_SCL | IO | V_PAD_1V8 | I2C3 clock signal |

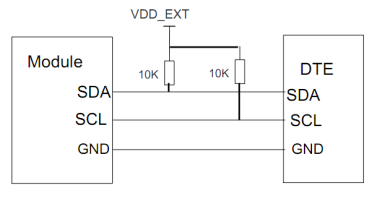

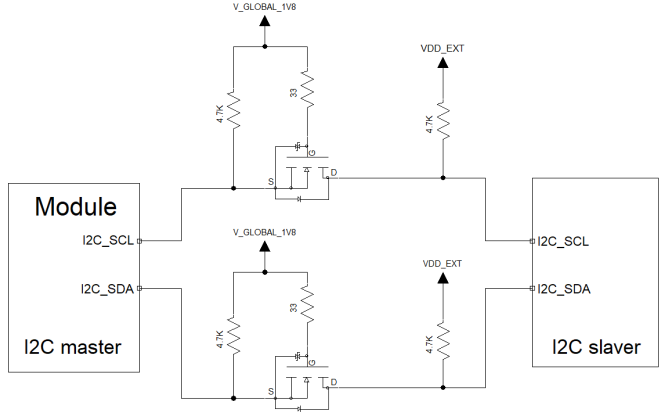

I2C is a simple serial communication bus protocol that uses just two bus wires, a serial data wire (SDA) and a serial clock wire (SCL). I2C is integrated into many ICs and allows devices to communicate directly with each other. Each device is recognized by a unique address to differentiate from other devices on the same I2C bus and can operate either as a transmitter or a receiver depending on its function.

Applications

The I2C bus must be pulled up to V_GLOBAL_1V8.

The voltage of the I2C bus is 1.8V. To connect to a 3.3V or 5V I2C device, a level translator is required.

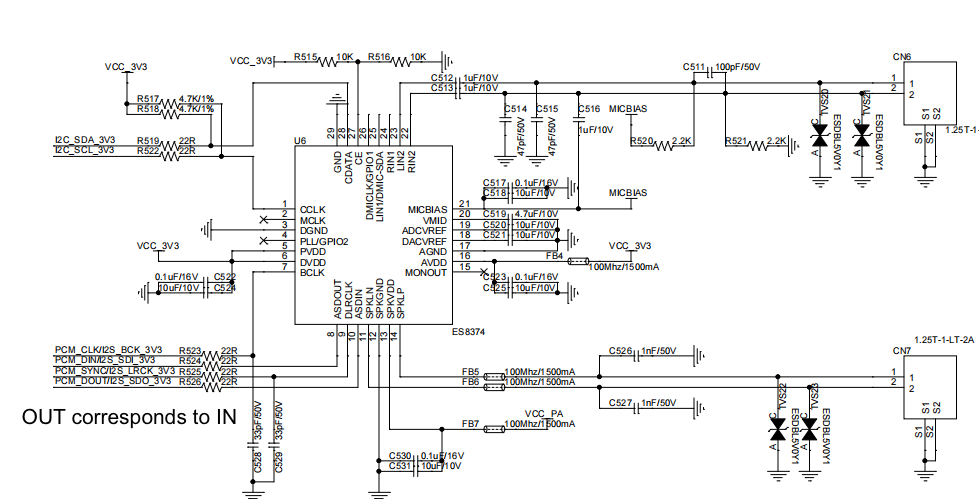

PCM interface

The module provides a digital PCM interface. In OpenCPU mode, you can use an external codec by reusing the PCM and SPI flash pins.

Pin description

| Pin No. | Pin name | I/O type | Power supply domain | Description |

|---|---|---|---|---|

| 58 | PCM_SYNC/SPI_FLASH_CS | DO | V_PAD_1V8 | PCM audio sync |

| 59 | PCM_DIN/SPI_FLASH_D0 | DI | V_PAD_1V8 | PCM audio input |

| 60 | PCM_DOUT/SPI_FLASH_D1 | DO | V_PAD_1V8 | PCM audio output |

| 61 | PCM_CLK/SPI_FLASH_CLK | DO | V_PAD_1V8 | PCM audio clock signal |

Applications

The PCM and I2C are 1.8V. If the codec chip is 3.3V, a level converter is required.

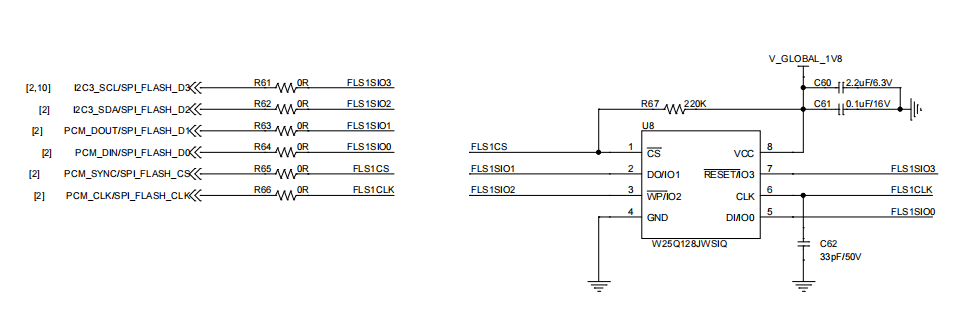

SPI flash

The module has a built-in 64 MB NOR flash. If it is not sufficient for your applications, you can add an external SPI flash. This interface can be reused as PCM.

Pin description

| Pin No. | Pin name | I/O type | Power supply domain | Description |

|---|---|---|---|---|

| 61 | PCM_CLK/SPI_FLASH_CLK | DO | V_PAD_1V8 | Flash SPI clock signal |

| 58 | PCM_SYNC/SPI_FLASH_CS | DO | V_PAD_1V8 | Flash SPI chip select signal |

| 59 | PCM_DIN/SPI_FLASH_D0 | IO | V_PAD_1V8 | Flash SPI data bit 0 |

| 60 | PCM_DOUT/SPI_FLASH_D1 | IO | V_PAD_1V8 | Flash SPI data bit 1 |

| 69 | I2C3_SDA/SPI_FLASH_D2 | IO | V_PAD_1V8 | Flash SPI data bit 2 |

| 70 | I2C3_SCL/SPI_FLASH_D3 | IO | V_PAD_1V8 | Flash SPI data bit 3 |

Applications

For more information about the supported flash models, see the embedded development documentation.

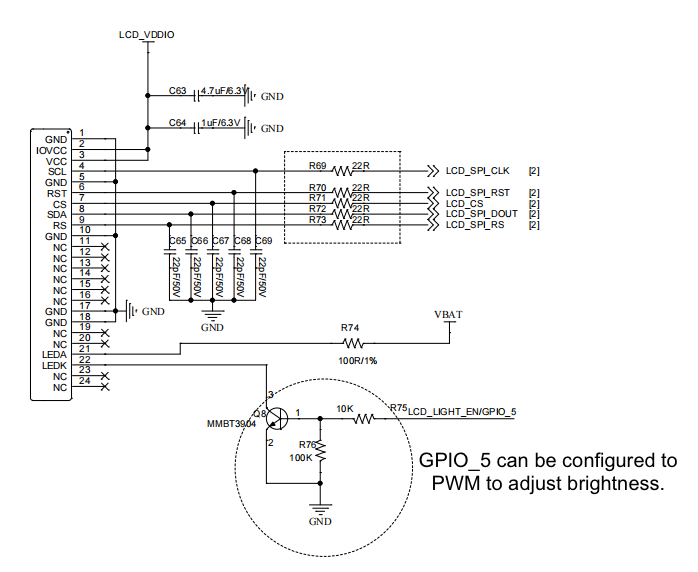

LCD SPI

The module provides a dedicated SPI to drive an LCD.

- The maximum resolution for SPI display can be 320 × 240 pixels at 30 fps.

- Built-in image processing.

- Supported formats: YUV 4:2:0, YUV 4:2:2, RGB 565, and ARGB 8888.

- Currently, only support 4-wire, 8-bit, 1-channel LCD.

- Support 1.8V/2.8V LCD.

Pin description

| Pin No. | Pin name | I/O type | Power supply domain | Description |

|---|---|---|---|---|

| 62 | LCD_TE | DO | V_LCD | LCD SPI frame sync signal |

| 63 | LCD_SPI_RS | DO | V_LCD | LCD SPI register select |

| 64 | LCD_RST | DO | V_LCD | LCD SPI reset signal |

| 65 | LCD_SPI_CS | DO | V_LCD | LCD SPI chip select signal |

| 66 | LCD_SPI_DOUT | DO | V_LCD | LCD SPI data signal |

| 67 | LCD_SPI_CLK | DO | V_LCD | LCD SPI clock signal |

| 134 | LCD_VDDIO | PO | Digital power supply for LCD, defaulting to 1.8V. IOMAX = 200 mA. |

|

| 138 | LCD_AVDD | PO | Analog power supply for LCD, defaulting to 3.0V. IOMAX = 150 mA. |

Applications

Circuit design

- Reserve a resistor-capacitor circuit to reduce RF interference.

VBATis the positive power supply of the LCD backlight. Power design is based on the requirements of the LCD.- The brightness of the backlight is adjusted by PWM duty cycle.

- The R74 resistor is adjusted based on the turn-on current flowing through the LCD backlight.

Camera SPI

The module provides a camera SPI input interface for scanning QR code and taking photos. Video shooting is not supported.

- The maximum resolution can be 640 × 480 pixels.

- Supported formats: YUV 422, Y 420, RAW 8, and RAW 10.

- Integrated with GC0310 driver.

Pin description

| Pin No. | Pin name | I/O type | Power supply domain | Description |

|---|---|---|---|---|

| 10 | CAM_MCLK | DO | V_PAD_1V8 | Camera MCLK output. |

| 11 | CAM_I2C_SCL | DO | V_PAD_1V8 | Camera I2C clock signal |

| 12 | CAM_I2C_SDA | IO | V_PAD_1V8 | Camera I2C data signal |

| 13 | CAM_SPI_CLK | DI | V_PAD_1V8 | Camera SPI clock input. |

| 14 | CAM_SPI_D0 | DI | V_PAD_1V8 | Camera SPI data input 0. |

| 15 | CAM_SPI_D1 | DI | V_PAD_1V8 | Camera SPI data input 1. |

| 16 | CAM_PWDN | DO | V_PAD_1V8 | Camera shutdown signal. |

| 120 | CAM_RST | DO | V_PAD_1V8 | Camera reset signal. |

| 17 | CAM_VDD | PO | Analog power supply for camera, with voltage ranging from 1.6V to 3.2V, and defaulting to 1.8V. IOMAX = 100 mA. By default, the analog power is down after the module is powered on. |

|

| 68 | CAM_VDDIO | PO | Digital power supply for camera, with voltage ranging from 1.4V to 2.1V, and defaulting to 1.8V. IOMAX = 100 mA. By default, the digital power is down after the device is powered on. |

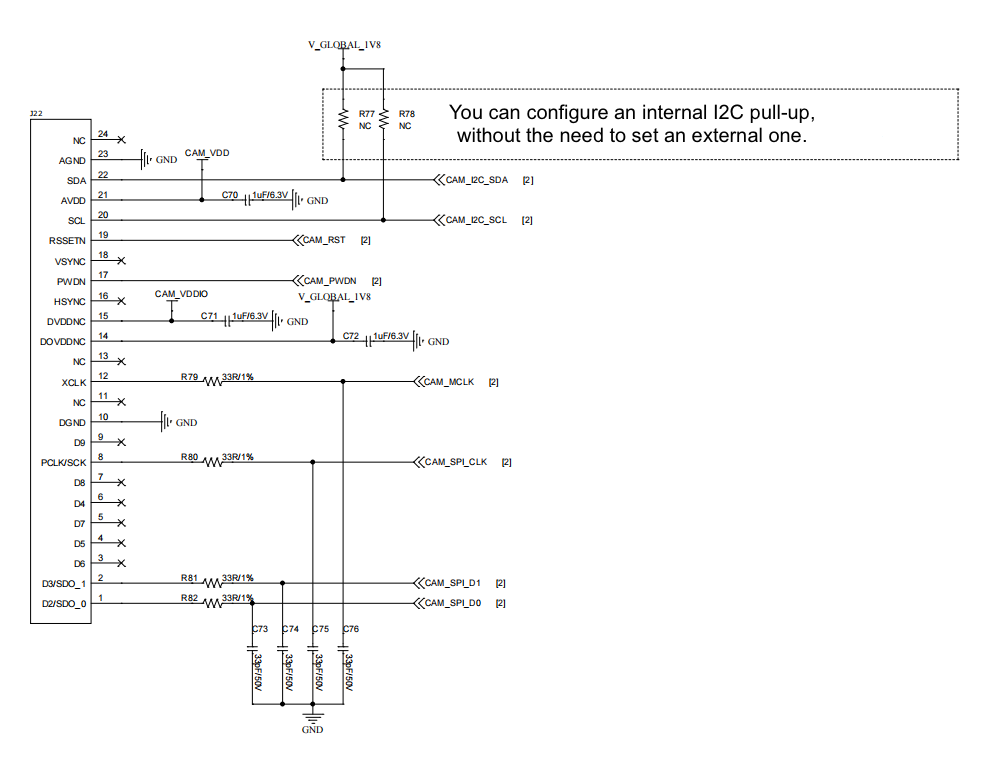

Applications

Circuit design

-

Connect a 33Ω resistor and a 33 pF capacitor in series on the CAM signal trace to reduce RF interference.

-

Place the filter capacitor on

AVDD,DVDD, andDOVDDclose to the connector. -

Keep camera signal traces away from

RFandVBATtraces. This is especially crucial for clock and signal traces. -

Surround the clock and signal traces with ground to reduce RF interference.

-

Surround the analog power supply

CAM_VDDwith ground.CAM_VDDpowers the analog signals of the camera.

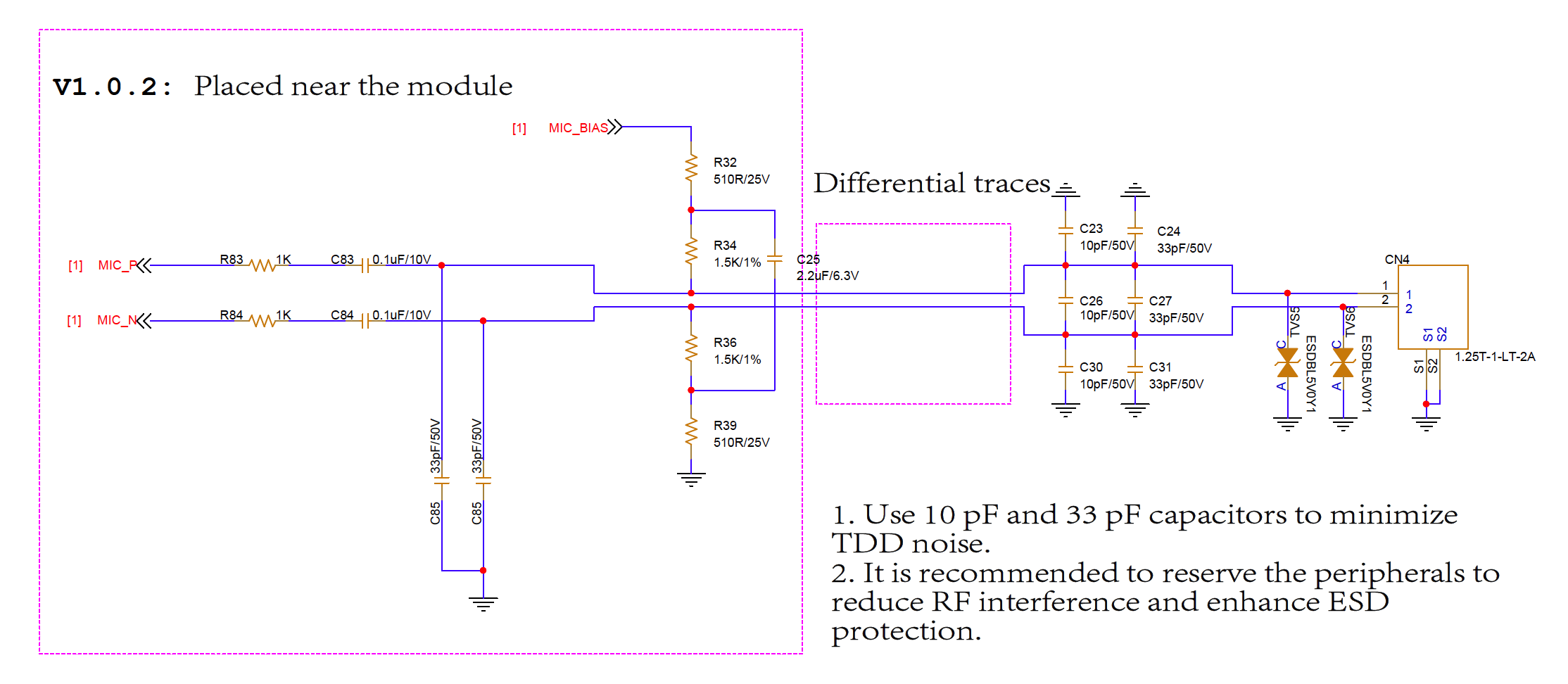

Microphone

The module provides an analog audio input interface.

Pin description

| Pin No. | Pin name | I/O type | Description |

|---|---|---|---|

| 23 | MIC- | AI | Negative microphone input signal. |

| 24 | MIC+ | AI | Positive microphone input signal. |

| 25 | MIC_BIAS | PO | Microphone bias voltage. |

Applications

Circuit design

-

Route the

MIC+andMIC-signal traces as parallel differential pairs with equal lengths. -

Place 33 pF and 10 pF filter capacitors near the microphone to reduce EMI.

-

Place a TVS protector near the microphone to provide immunity to electrostatic discharge (ESD) and voltage surges.

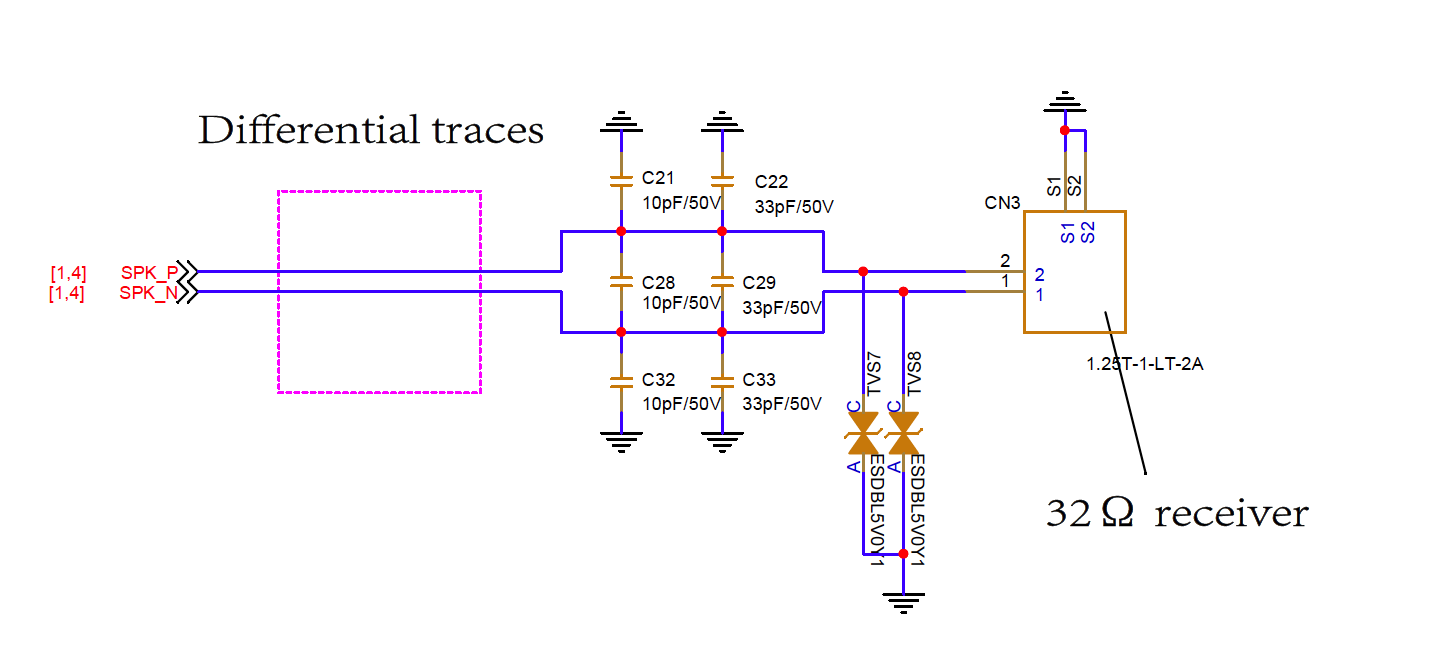

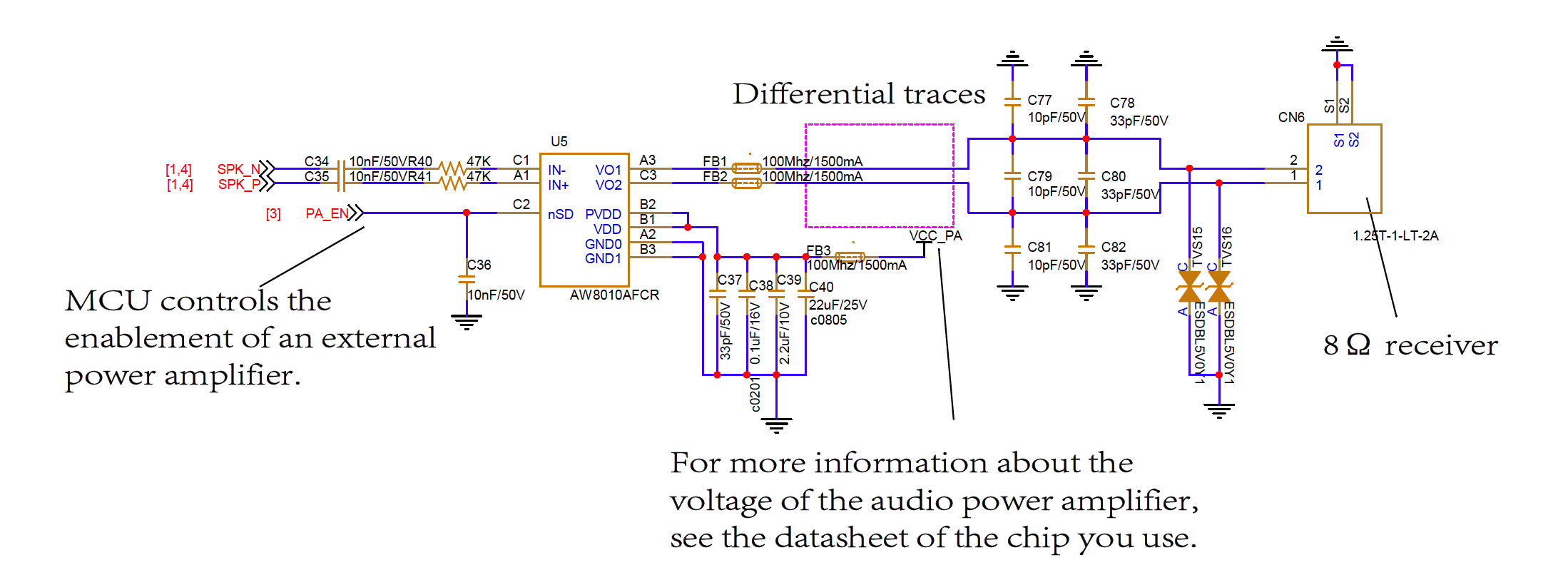

Speaker

The module provides an analog audio output interface.

Pin description

| Pin No. | Pin name | I/O type | Description |

|---|---|---|---|

| 21 | SPK- | AI | Negative audio differential output, with no built-in power amplifier. It can drive a 32Ω receiver. An external power amplifier is required to connect to an 8Ω external speaker. |

| 22 | SPK+ | AI | Positive audio differential output, with no built-in power amplifier. It can drive a 32Ω receiver. An external power amplifier is required to connect to an 8Ω external speaker. |

Applications

The audio output directly drives a 32Ω receiver, without a built-in power amplifier.

The reference circuit for adding a power amplifier.

Circuit design

-

Route the

SPK+andSPK-signal traces as parallel differential pairs with equal lengths. -

Place 33 pF and 10 pF filter capacitors near the microphone to reduce EMI.

-

Place a TVS protector near the speaker to provide immunity to electrostatic discharge (ESD) and voltage surges.

ADC

The module provides two ADC input interfaces.

Pin description

| Pin No. | Pin name | I/O type | Description |

|---|---|---|---|

| 19 | ADC0 | AI | Analog-to-digital converter (ADC). Input voltage: 0 to VBAT Channel: 0 Resolution: 11 Bits |

| 20 | ADC1 | AI | Analog-to-digital converter (ADC). Input voltage: 0 to VBAT Channel: 0 Resolution: 11 Bits |

ADC performance

| Parameter | Condition | Min Value | Typical value | Max value | Unit |

|---|---|---|---|---|---|

| Resolution | - | - | 11 | - | Bit |

| Input voltage range | Input scale ratio = 1:1 | 0 | - | 1.25 | V |

| Input scale ratio = 1.92:1 | 0 | - | 2.4 | V | |

| Input scale ratio = 1.92:1 | 0 | - | 2.4 | V | |

| Input scale ratio = 2.56:1 | 0 | - | 3.2 | V | |

| Input scale ratio = 4:1 | 0 | VBAT | 5 | V | |

| Precision | Input scale ratio = 1:1 | - | 10 | - | mV |

|

- | 20 | - | mV | |

| Conversion time | - | - | 50 | - | µs |

Circuit design

- The ADC interface should not accept an input voltage without a power supply from

VBAT. - The input voltage limit for the ADC is 5V.

- The default scale of the ADC is 0 to

VBAT. If the input voltage exceedsVBAT, it can cause unacceptable errors in ADC measurements. - You can set the scale in the software to adjust ADC measurement accuracy.

MAIN_RI and MAIN_DTR

Pin description

| Pin No. | Pin name | I/O type | Description |

|---|---|---|---|

| 39 | MAIN_DTR | DI | Wake up control. |

| 40 | MAIN_RI | DO | UART1 ring indicator. |

MAIN_RI

In AT mode or MCU integration mode, when the module sends packets through the main UART or USB port, MAIN_RI indicates the status.

| State | MAIN_RI signal |

|---|---|

| IDLE | High level. |

| AT mode | When an unsolicited result code (URC) is returned, MAIN_RI is pulled down and kept low for 120 ms and then returned high. |

| MCU integration | When an unsolicited result code (URC) is returned, MAIN_RI is pulled down and kept low for 60 ms and then returned high. You can use the serial communication command to set the low-level hold time between 10 ms and 10s. |

MAIN_DTR

When the module is in sleep mode, MAIN_DTR can be used to wake up the module.

| State | MAIN_RI signal |

|---|---|

| Sleep | High level. Pull-down does not put the module to sleep. |

| WAKEUP | The host pulls down MAIN_DTR to wake up the module. |

Antenna interface

Pin description

| Pin No. | Pin name | Description |

|---|---|---|

| 46 | LTE_ANT | LTE Antenna |

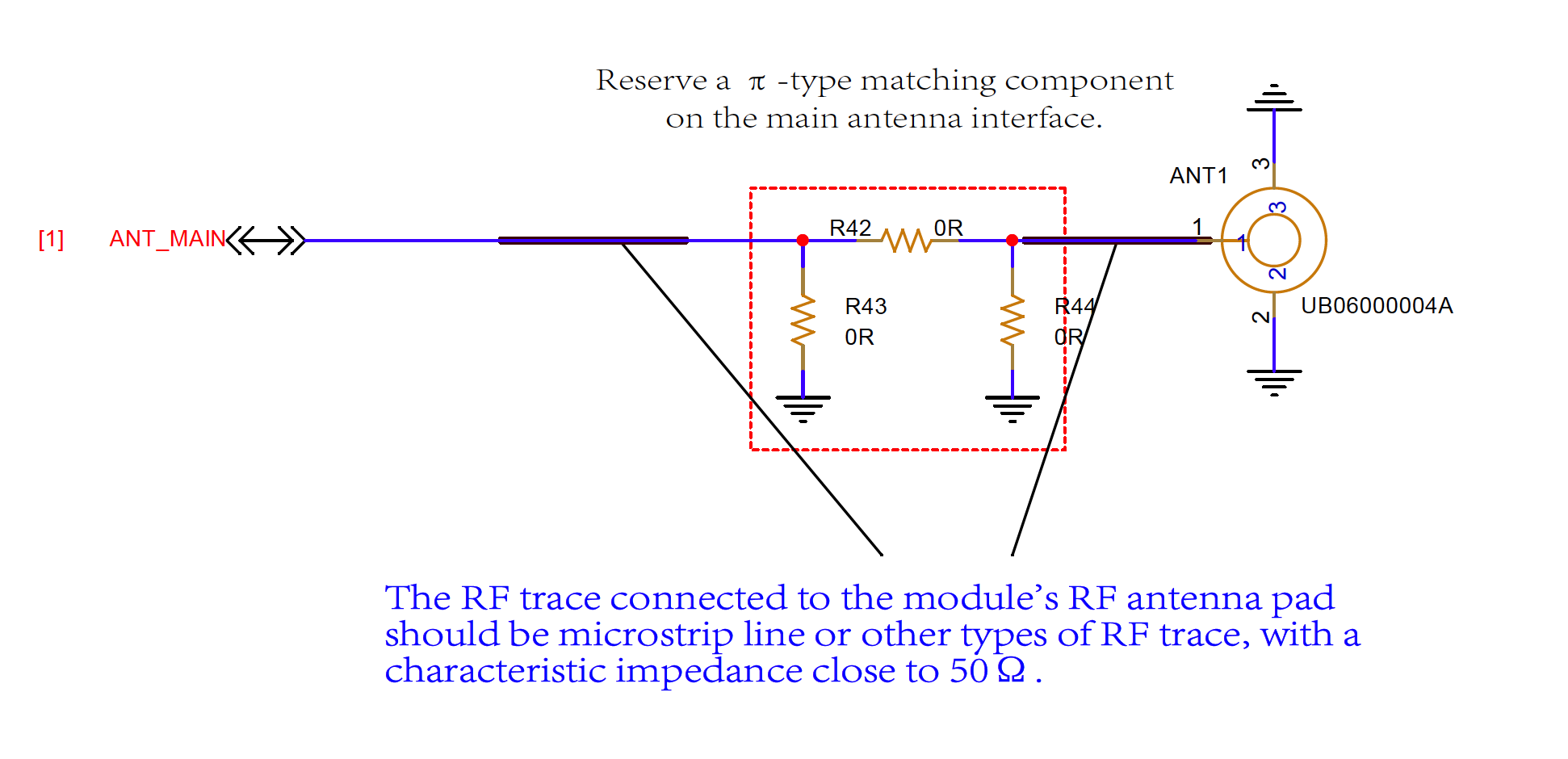

Antenna matching circuit

In order to achieve better RF performance, it is recommended to place the π-type matching components as close to the antenna as possible.

By default, the capacitors (C1/C2) are not mounted and a 0Ω resistor is mounted on L1.

LTE antenna:

RF layout

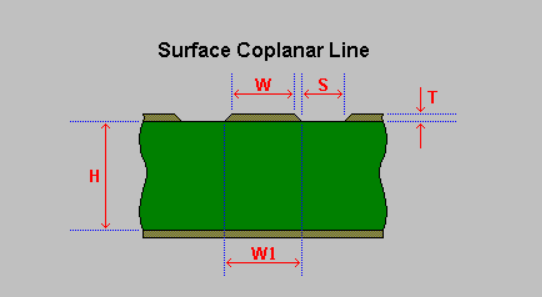

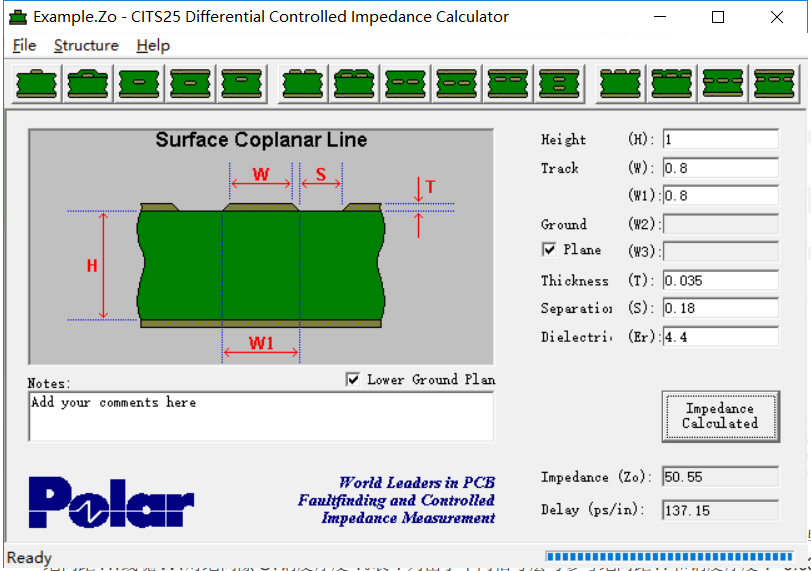

For MCU PCB, the characteristic impedance of all RF traces should be controlled as 50Ω. A microstrip line is used for impedance control.

Microstrip line design on PCB

Principles in RF layout design:

- The distance between the RF pins and the RF connector should be as short as possible. All the right angle traces should be changed to 135° or curved ones.

- The reference ground of RF traces should be complete. Add some ground vias around RF traces. The distance between the ground vias and RF traces should be no less than two times the width of RF signal traces.

- The GND pins are adjacent to RF pins and should be fully connected to the ground.

- There should be a distance between the pad connected to the signal pin and the ground plane.

- Use an impedance simulation tool to control the characteristic impedance of RF traces as 50Ω.

- If you use an external antenna, add a TVS diode to prevent ESD damage. The TVS diode’s junction capacitance (Cj in pF) should be less than 0.5 pF.

The following figure provides parameters used for impedance control. You can adjust the trace width properly to get the trace impedance closer to 50Ω.

Antenna design requirements

- The antenna should be kept away from components that are more likely to generate EMI, such as power source and data line.

- To maximize the RF performance, the distance between the antenna and the PCB or mental materials should be at least 15 mm.

- Make sure that the enclosure surrounding the antenna is not metal materials. Otherwise, the radiation performance might be degraded. It is recommended to hollow out the breakout board around the antenna area.

Antenna types

This module does not come with an antenna, so an external antenna is required. You can choose one from the external rubber antenna, helical antenna, FPC antenna with IPEX connector, and PCB antenna. The antenna type can be monopole, planar inverted-F antenna (PIFA), inverted-F antenna (IFA), loop, and more.

The following figure shows the common antennas.

-

Rubber antenna

-

FPC antenna with IPEX connector

-

Built-in FPC antenna

Reliability design

EMC and ESD suppression design guide

Electromagnetic compatibility (EMC) is one of the essential considerations in designing for signal integrity and power integrity.

- When you design the peripheral circuit, have two times the width of the trace when routing signals close to each other to minimize noise coupling and generation.

- Place decoupling capacitors close to voltage pins. Keep the high-frequency and high-speed circuits and sensitive circuits away from the edge of the PCB. To reduce crosstalk between signals, increase the spacing between the traces. Provide shielding for components that emit RFI and EMI waves to protect sensitive signals from interference.

Design considerations for ESD circuit protection.

- Place ESD protection devices close to the critical signal I/Os, such as the SIM card, USB port, and TF card.

- In PCB layout and design, make sure the metal shielding enclosure is fully connected to the ground.

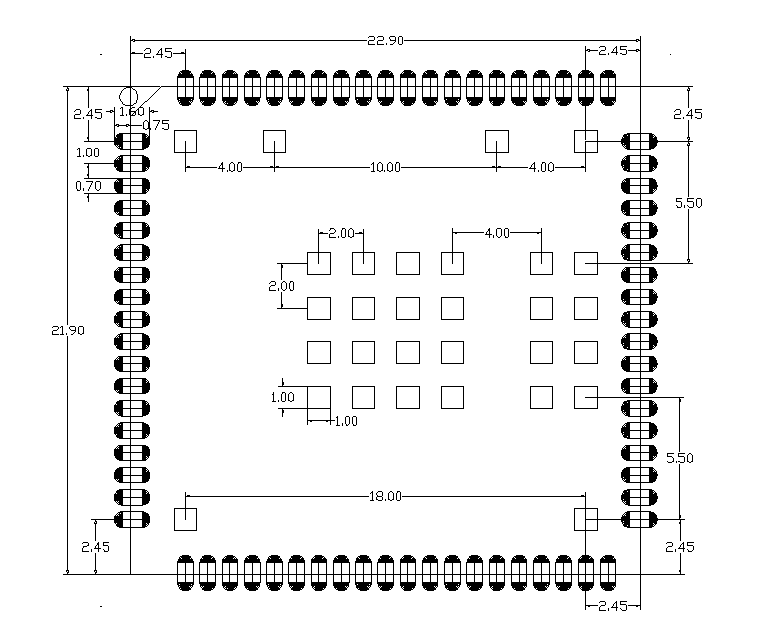

PCB pad design

It is recommended to design the 64 pads placed in the middle of the PCB as per the dimensions specified in the structure diagram. Extend the 80 pads around the PCB to the module for over 0.3 mm and the other three sides of the pads for 0.05 mm.

Thermal design

The module generates heat when it works or might be affected by high-temperature components. The module design ensures good heat dissipation. When connecting the module to the PCB, connect the thermal pad to the ground properly to ensure thermal conduction and balance and better electrical performance.

-

Place the module away from the power supply and high-speed signals and protect the traces of sources of EMI.

-

Place the antenna and the coaxial cable that is used to connect the antenna and network interface controller (NIC) away from these sources of EMI.

-

Place the module away from components that generate a large amount of heat such as the CPU. Otherwise, the RF performance might be degraded.

Packing and manufacturing

Mechanical dimensions

TCS600U is equipped with a total of 106 pins, including 76 LCC pins and 30 LGA pins.

The dimensions are 21.9 mm±0.35 (W) × 22.9 mm±0.35 (L) × 2.4 mm±0.15 (H), as shown below. The PCB thickness is 0.8 mm±0.1 mm.

The tolerances for dimensions of length and width, height, and PCB thickness are ±0.35 mm, ±0.15 mm, and ±0.1 mm respectively.

SMT package

Stencil opening design

- Stencil thickness: The stencil thickness of the area for the module should be partly stepped up to 0.18 mm–0.2 mm.

- LCC pins: The stencil openings are shrunk inward by 0.1 mm, and moved outward by 1 mm along the direction of length. Along the width direction, the stencil openings are shrunk inward by 0.16 mm (each side by 0.08 mm) with a length of 1.4 mm (module’s lead length, avoiding solder beads), and are moved outward by 0.2 mm (each side by 0.1 mm) with a length of 2 mm (exposed on the areas outside of the bottom of the module leads must get increased tinning).

- LGA pins: The total opening area of the stencil should be 60% of the pad. If it exceeds 60%, you can set a pitch of 0.3 mm.

Is this page helpful?

YesFeedbackIs this page helpful?

YesFeedback