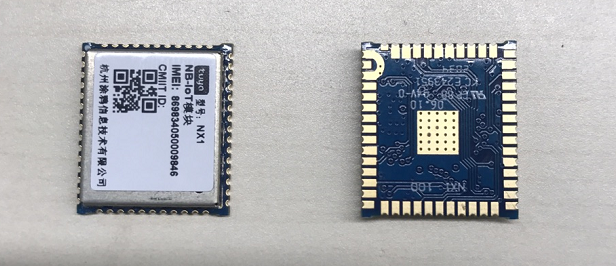

NX1-CT Module Datasheet

Last Updated on : 2024-06-14 03:09:09download

Developed by Tuya, NX1-CT is a low-power embedded LPWA module in the NB-IoT series. It supports the NB-IoT radio communication protocol (3GPP Rel.14). NX1-CT contains a highly integrated Soc XY1100 (which consists of an application processor, a low-power multi-band NB-IoT transceiver, and a PMU) and a few peripherals.

Product overview

NX1-CT is integrated with 152-KB SRAM, 32-MB NOR flash memory, and supports interfaces including UART, I2C, SPI, PWM, 4-channel CSP, UTC, and USIM.

Features

- Embedded low-power 32-bit processor

- Power supply

- Working voltage: 2.2 to 4.2V

- Typical working voltage: 3.3 V

- Peripherals: 18 GPIOs, 3 UARTs, 1 ADC, 1 SPI, and 1 I2C

- SIM: 3V/1.8V SIM card

- NB-IoT network

- Cat NB 1/Cat NB 2

- 3GPP R14 NB-IoT Standards

- B5/B8

- Maximum transmit power: 23 dBm±2 dB

- Receiving sensitivity <- 126 dBm/15 kHz (not retransmission)

- 50Ω characteristic impedance, an antenna provided by the third party

- Data rate:

- Single-tone: 25.5 kbps (downlink) and 16.7 kbps (uplink)

- Multi-tone: 25.5 kbps (downlink) and 62.5 kbps (uplink)

- Network protocol feature: UDP/TCP/CoAP/LWM2M/ PPP*/SSL*/DTLS*/FTP*/ HTTP*/MQTT*/HTTPS*

- Normal working temperature: -35°C to +75°C

- Extended working temperature: -40°C to +85℃

- Storage temperature: -40°C to +125℃

- Upgrade through the main serial interface, FOTA

Applications

- Public utilities: meter reading (water, gas, and electricity), intelligent water affairs (pipe network, leakage and quality inspection), smart fire extinguisher, fire hydrant, etc.

- Smart health: drug traceability, remote medical monitoring, blood pressure meter, blood glucose meter, heart armor monitoring, baby monitor, etc.

- Smart city: smart street lights, smart parking, urban trash can management, public safety alarms, urban environment monitoring (water pollution, noise, air quality PM2.5, etc.)

- Consumers: wearable devices, bicycles, mopeds anti-theft, smart luggage, VIP tracking (children, elderly, pets, and vehicle rental), and payment/POS machines

- Agricultural environment: precision planting (environment parameters: water, temperature, sunshine, biocide, and fertilizer), animal husbandry (health and tracking), aquaculture and food safety traceability

- Logistics warehousing: asset, container tracking, warehouse management, fleet management tracking, and logistics status tracking

- Smart building: access control, smart HVAC, smoke detection, fire detection, and elevator failure/repair

- Manufacturing industry: production, equipment status monitoring, energy facilities, oil and gas monitoring, chemical park monitoring, large-scale rental equipment, and predictive maintenance (home appliances, machinery, etc.)

Change history

| Update date | Updated content | Version after update |

|---|---|---|

| 12/18/2020 | This is the first release. | V1.0.0 |

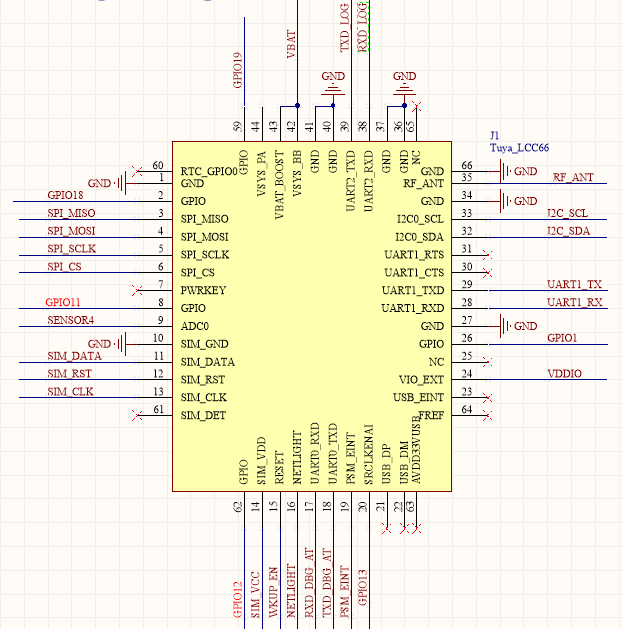

Module interfaces

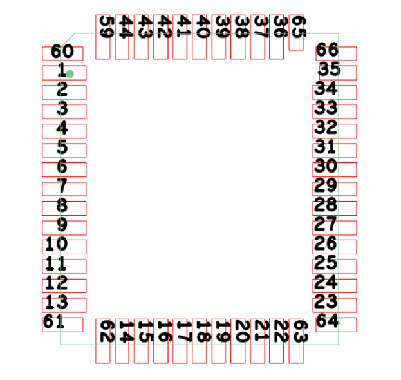

Pin distribution

NX1-CT has 52 LCC pins in total. This chapter illustrates module interfaces and their definitions in detail.

Pin definition

| Pin number | Symbol | I/O type | Function | Remarks |

|---|---|---|---|---|

| 1 | GND | – | GND | – |

| 2 | GPIO 18 | I/O | Correspond to Pin 33 on the internal IC | Common GPIO |

| 3 | SPI_MISO | I | Master input slave output/GPIO 6 | 1.8V, support only the slave mode |

| 4 | SPI_MOSI | O | Master output slave input/GPIO 7 | 1.8V, support only the slave mode |

| 5 | SPI_SCLK | O | Serial clock signal/GPIO 8 | 1.8V, support only the slave mode |

| 6 | SPI_CS | O | Chip select/GPIO 9 | 1.8V, support only the slave mode |

| 7 | NC | - | NC | |

| 8 | GPIO 11 | I/O | Correspond to Pin 40 on the internal IC | Common GPIO, which cannot be pulled high when powered on |

| 9 | ADC | I | A universal analog-to-digital converter Pad_io_Sensor_Test2 | 12-bit AUXADC |

| 10 | SIM_GND | – | A SIM card dedicated place | – |

| 11 | SIM_DATA | – | SIM card data signal | – |

| 12 | SIM_RST | – | SIM card reset signal | – |

| 13 | SIM_CLK | – | SIM card clock signal | – |

| 14 | SIM_VCC | – | SIM card power supply | 1.8/3.0 V |

| 15 | RESET | I | Resetting pin | 1.8V WKUP_EN, when the signal lasts more than 6s at the low level, it is a reset signal. |

| 16 | NETLIGHT | I/O | GPIO 5, which corresponds to Pin 51 on the internal IC | A universal GPIO interface If you need the network indication function, the PIN is recommended |

| 17 | RXD_DBG_AT | I | A main serial interface, which is used for receiving data and works as a programming calibration interface | 1.8 V Please pay attention to level conversion |

| 18 | TXD_DBG_AT | O | A main serial interface, which is used for transmitting data and works as a programming calibration interface | 1.8 V Please pay attention to reference level conversion |

| 19 | PSM_EINT | I | Wakeup pin | 3.3V WKUP_EN, when the signal lasts more than 100us and less than 6s at the low level, it is the wakeup signal. |

| 20 | GPIO 13 | I/O | Correspond to Pin 39 on the internal IC | Common GPIO |

| 21 | NC | – | NC | – |

| 22 | NC | – | NC | – |

| 23 | NC | – | NC | – |

| 24 | VIO18_EXT | O | 1.8V output power supply (no output in PSM mode) | Vmin=1.62V,Vnorm=1.8V |

| 25 | NC | – | NC | – |

| 26 | GPIO 1 | I/O | Correspond to Pin 3 on the internal IC | Common GPIO |

| 27 | GND | – | GND | – |

| 28 | UART1_RXD | I | A default universal docking user serial interface, which is used for receiving data | 1.8V Please pay attention to reference level conversion |

| 29 | UART1_TXD | O | A default universal docking user serial interface, which is used for transmitting data | 1.8V Please pay attention to reference level conversion |

| 30 | NC | – | NC | – |

| 31 | NC | – | NC | – |

| 32 | I2C_SDA | I/O | I2C0_data/GPIO3 | A default I2C interface |

| 33 | I2C_SCL | O | I2C0_clock/GPIO2 | A default I2C interface |

| 34 | GND | – | GND | – |

| 35 | RF_ANT | – | RF_antenna | 50Ω characteristic impedance |

| 36, 37 | GND | – | GND | – |

| 38 | RXD_LOG | I | Receive data | By default, it is a log serial interface. 1.8V Please pay attention to the reference level conversion |

| 39 | TXD_LOG | O | Transmit data | By default, it is a log serial interface. 1.8V Please pay attention to the reference level conversion |

| 40, 41 | GND | – | GND | – |

| 42, 43 | VBATT | I | Input power | V=2.2 to 4.2V, V-norm=3.3V |

| 44 | NC | – | NC | – |

| 59 | GPIO 19 | I/O | Correspond to Pin 32 on the internal IC | Common GPIO |

| 60 | NC | – | NC | – |

| 61 | NC | – | NC | – |

| 62 | GPIO 11 | I/O | Correspond to Pin 41 on the internal IC | Common GPIO, which cannot be pulled high when powered on |

| 63 | NC | – | NC | – |

| 64 | NC | – | NC | – |

| 65 | GPIO 10 | I/O | Correspond to Pin 43 on the internal IC | Common GPIO, which cannot be pulled high when powered on |

| 66 | GND | – | GND | – |

Note: “*” indicates “still under development” and “currently not supported”.

Electrical parameters

Absolute electrical parameters

| Parameter | Description | Minimum value | Maximum value | Unit |

|---|---|---|---|---|

| Ts | Storage temperature | -40 | 125 | ℃ |

| VBAT | Power supply voltage | 2.2 | 4.2 | V |

| Contact discharge | VBAT, GND | -5 | +5 | KV |

| Contact discharge | Antenna interface | -5 | +5 | KV |

| Contact discharge | Other interfaces | -0.5 | +0.5 | KV |

| Air discharge | VBAT, GND | -10 | +10 | KV |

| Air discharge | Antenna interface | -10 | +10 | KV |

| Air discharge | Other interfaces | -1 | +1 | KV |

Normal working conditions

| Parameter | Description | Minimum value | Typical value | Maximum value | Unit |

|---|---|---|---|---|---|

| Ta | Working temperature | -40 | 25 | 85 | ℃ |

| VBAT | Power supply voltage | 2.2 | 3.3 | 4.2 | V |

| VIL | I/O low level input | -0.3 | - | 0.3 | V |

| VIH | I/O high level input | VDDIO-0.3 | - | VDDIO+0.3 | V |

| VOL | I/O low level output | -0.3 | - | 0.3 | V |

| VOH | I/O high level output | VDDIO-0.3 | - | VDDIO+0.3 | V |

| Imax | I/O drive current | - | 30 | - | mA |

TX and RX power consumption

| Working Mode | Description | Average Value | Peak Value (Typical Value) | Unit |

|---|---|---|---|---|

| PSM | Deep Sleep | 1.5 | 2.5 | μA |

| Idle | @DRX=1.28S | 374 | / | μA |

| Idle | @DRX=2.56S | 303 | / | μA |

| Single-tone carrier frequency of 15KHz | B5@23 dBm | 181 | 359 | mA |

| Single-tone carrier frequency of 15KHz | B8@23 dBm | 186 | 346 | mA |

| Single-tone carrier frequency of 3.75KHz | B5@23 dBm | 264 | 363 | mA |

| Single-tone carrier frequency of 3.75KHz | B8@23 dBm | 268 | 353 | mA |

RF parameters

Basic RF features

| Parameter | Description |

|---|---|

| Working frequency | Band 5: 824 to 849 MHz; 869 to 894 MHz, Band 8: 880 to 915 MHz; 925 to 960 MHz |

| NB-IoT standards | 3GPP 36.521 |

| 6.2.2F UE maximum output power for category NB1 | |

| 6.2.3F maximum power reduction (MPR) for category NB1 | |

| 6.2.5F configured UE transmitted output power for UE category NB1 | |

| 6.3.2F minimum output power for category NB1 | |

| 6.3.3F transmit off power for category NB1 | |

| 6.3.4 F1 on/off time mask for category NB1 | |

| 6.3.4.F2 NPRACH time mask for category NB1 | |

| 6.3.5F.2 power control relative power tolerance for category NB1 | |

| 6.3.5F.1 power control absolute power tolerance for category NB1 | |

| 6.5.1F frequency error for category NB1 | |

| 6.5.2.1F.1 error vector magnitude (EVM) for category NB1 | |

| 6.5.2.2F carrier leakage for category NB1 | |

| 6.5.2.3F in-band emissions for non-allocated RB for category NB1 | |

| 6.6.1F occupied bandwidth for category NB1 | |

| 6.6.2.1F spectrum emission Mask for category NB1 | |

| 6.6.2.3F adjacent channel leakage power ratio for category NB1 | |

| 7.3F.1 reference sensitivity level without repetitions for category NB1 | |

| 7.4F maximum input level for category NB1 | |

| Data transmission rate | Single-tone: 25.5 kbps (downlink), 16.7 kbps (uplink) Multi-tone: 25.5 kbps (downlink), 62.5kbps (uplink) |

| Antenna type | Antenna provided by the third party (external antenna, FPC antenna, etc.) |

TX performance

TX performance

| Frequency band | Minimum value | Maximum value | Unit |

|---|---|---|---|

| B5 | <-39 | 23 dBm±2 dB | dBm |

| B8 | <-39 | 23 dBm±2 dB | dBm |

RX performance

RX sensitivity

| Frequency band | Typical value | Unit |

|---|---|---|

| Band5 | -126 dBm/15 KHz | dBm |

| Band8 | -126 dBm/15 KHz | dBm |

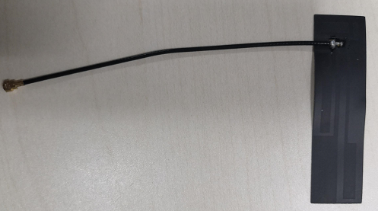

Antenna information

Antenna type

The module does not have its own onboard PCB antenna, and the third party needs to provide an antenna. The antenna can be an external rod antenna, a spring antenna, an IPEX- FPC antenna, a PCB board antenna, etc. The antenna forms include monopole antenna, PIFA antenna, IFA antenna, loop antenna, etc.

Antenna interference reduction

To ensure the optimal NB-IoT performance, it is recommended that the antenna be at least 10mm away from other metal parts.

Packaging information and production instructions

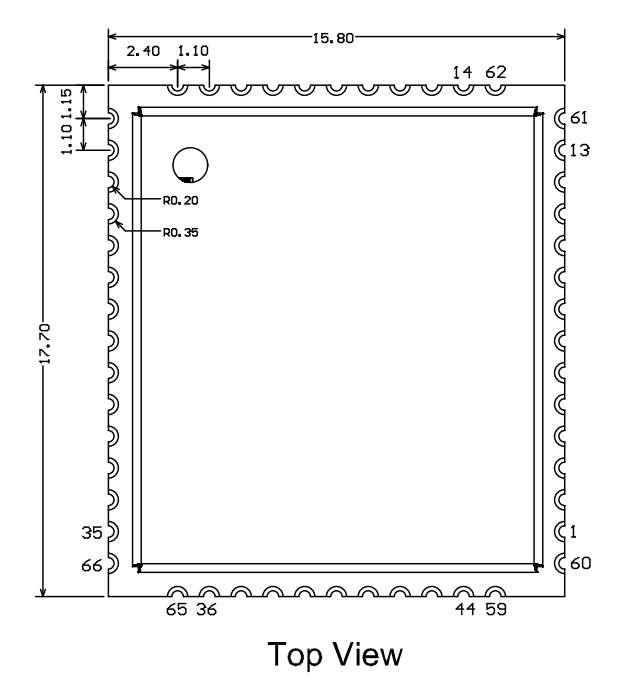

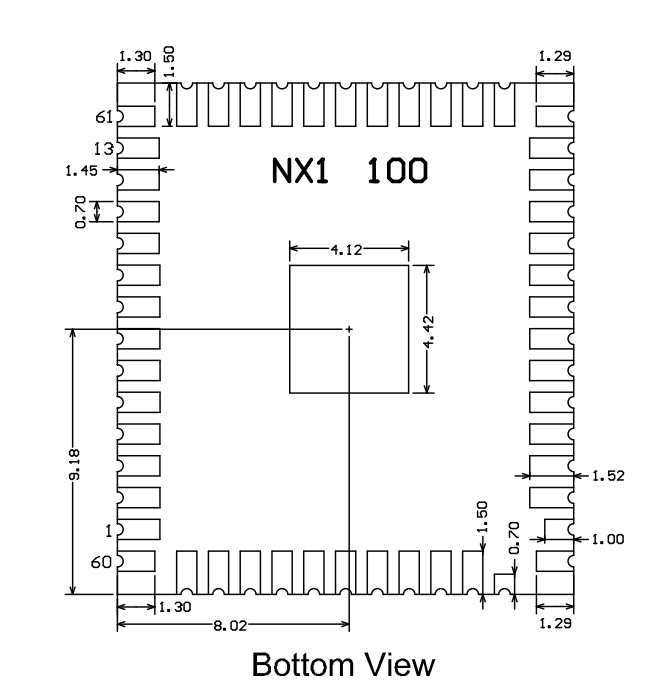

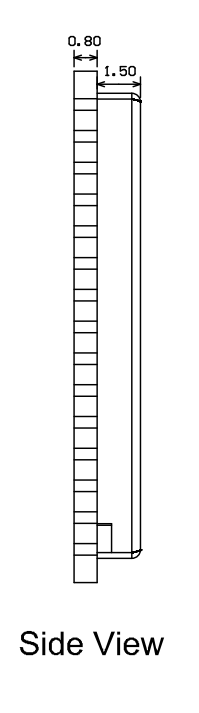

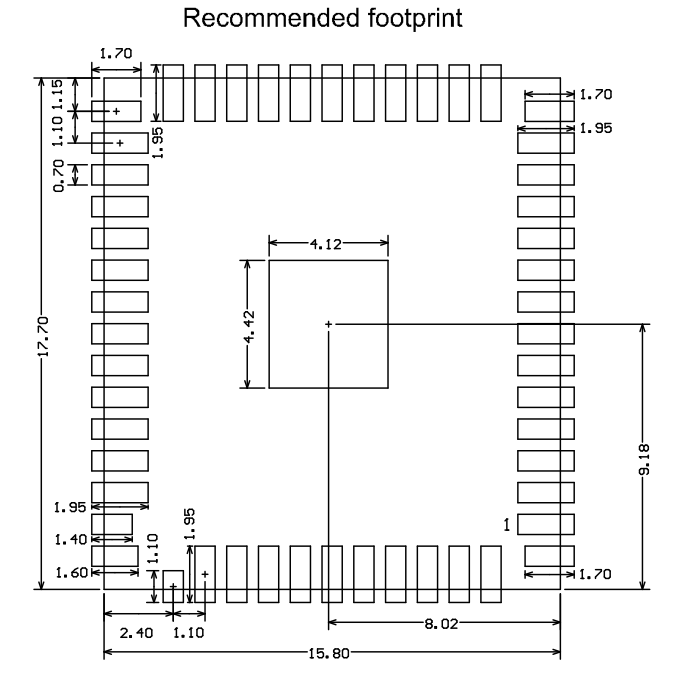

Mechanical dimensions

NX1 has 52 LCC encapsulation pins.

The dimensions of NX1 are 17.7±0.35 mm (L)×15.8±0.35 mm (W) ×2.4±0.15 mm (H), which are shown as belows:

Side view

The schematic diagram of footprint

PCB footprint diagram-SMT

Top/bottom/side view

Note: The length and width tolerance is ±0.35 mm, the height tolerance is ±0.15 mm, and the PCB thickness tolerance is ±0.1 mm. If you have any special requirements on dimensions, specify them clearly in the datasheet after communication.

Production instructions

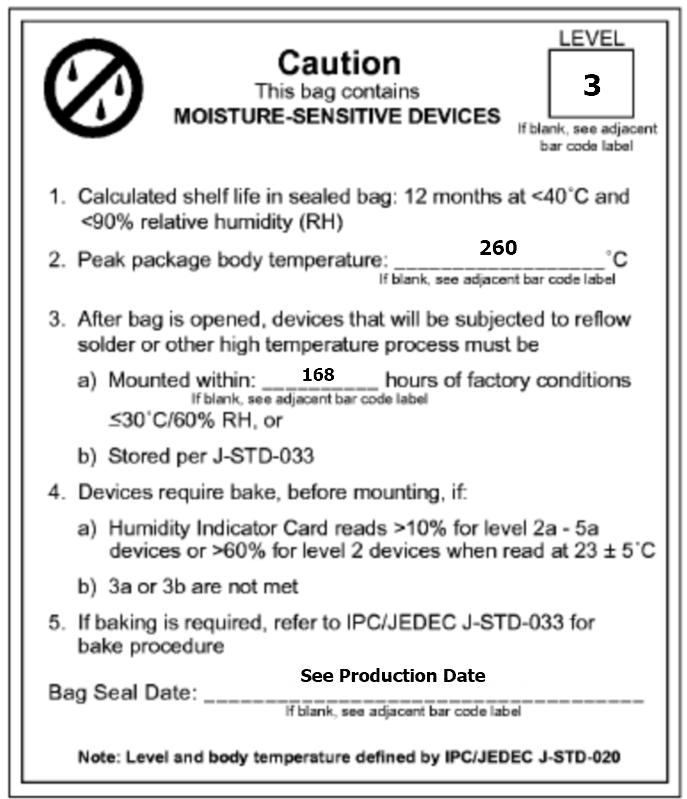

- The Tuya SMT module should be mounted by the SMT device. After being unpacked, it should be soldered within 24 hours. Otherwise, it should be put into the drying cupboard where the RH is not greater than 10%; or it needs to be packaged under vacuum again and the exposure time needs to be recorded (the total exposure time cannot exceed 168 hours).

- SMT devices:

- Mounter

- SPI

- Reflow soldering machine

- Thermal profiler

- Automated optical inspection (AOI) equipment

- Baking devices:

- Cabinet oven

- Anti-electrostatic and heat-resistant trays

- Anti-electrostatic and heat-resistant gloves

- SMT devices:

- Storage conditions for a delivered module:

-

The moisture-proof bag must be placed in an environment where the temperature is below 40°C and the relative humidity is lower than 90%.

-

The shelf life of a dry-packaged product is 12 months from the date when the product is packaged and sealed.

-

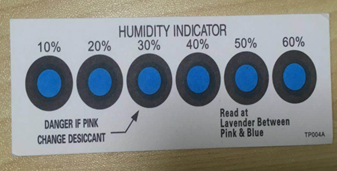

There is a humidity indicator card (HIC) in the packaging bag.

-

- The module needs to be baked in the following cases:

- The packaging bag is damaged before unpacking.

- There is no HIC in the packaging bag.

- After unpacking, circles of 10% and above on the HIC become pink.

- The total exposure time has lasted for over 168 hours since unpacking.

- More than 12 months have passed since the sealing of the bag.

- Baking settings:

- Temperature: 60°C and ≤ 5% RH for reel package and 125°C and ≤5% RH for tray package (please use the heat-resistant tray rather than plastic container)

- Time: 48 hours for reel package and 12 hours for tray package

- Alarm temperature: 65°C for reel package and 135°C for tray package

- Production-ready temperature after natural cooling: < 36°C

- Re-baking situation: If a module remains unused for over 168 hours after being baked, it needs to be baked again.

- If a batch of modules is not baked within 168 hours, do not use the reflow soldering to solder them. Because these modules are Level-3 moisture-sensitive devices, they are very likely to get damp when exposed beyond the allowable time. In this case, if they are soldered at high temperatures, it may result in device failure or poor soldering.

- In the whole production process, take electrostatic discharge (ESD) protective measures.

- To guarantee the passing rate, it is recommended that you use the SPI and AOI to monitor the quality of solder paste printing and mounting.

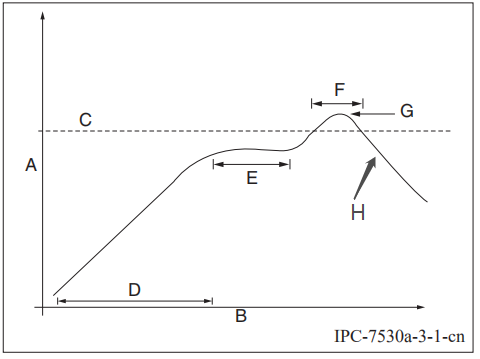

Recommended oven temperature curve

Set oven temperatures according to the following temperature curve of reflow soldering. The peak temperature is 245°C.

-

A: Temperature axis

-

B: Time axis

-

C: Liquidus temperature: 217 to 220°C

-

D: Ramp-up slope: 1 to 3°C/s

-

E: Duration of constant temperature: 60 to 120s; the range of constant temperature: 150 to 200°C

-

F: Duration above the liquidus: 50 to 70s

-

G: Peak temperature: 235 to 245°C

-

H: Ramp-down slope: 1 to 4°C/s

Note: The above curve is just an example of the solder paste SAC305. For more details about other solder pastes, please refer to Recommended oven temperature curve in the solder paste specifications.

Storage conditions

MOQ and packaging information

| Product number | MOQ (pcs) | Shipping packaging method | The number of modules per reel | The number of reels per carton |

|---|---|---|---|---|

| NX1-CT | 5600 | Tape reel | 1400 | 4 |

Is this page helpful?

YesFeedbackIs this page helpful?

YesFeedback