TCS600E Module Datasheet

Last Updated on : 2024-06-14 18:43:16download

TCS600E is an LTE Cat.1 cellular module. This module consists of a highly integrated LTE Cat.1 chip and peripheral circuits. It has a built-in LTE Cat.1 network communication protocol stack and a rich set of library functions.

Overview

The TCS600E module is built around an Arm Cortex-M3 processor and Cat.1 bis modem and embedded with a NOR flash of 4 MB and a PSRAM of more than 1 MB. It communicates over 4G LTE-TDD/FDD and provides a wide array of interfaces including USB, UART, I2C, I2S, ADC, and USIM card.

Features

- Built-in Arm Cortex-M3 application processor with 204 MHz CPU frequency

- Supply voltage range:

- Operating voltage range: 3.3V to 4.3V

- Typical operating voltage: 3.8V

- SIM card: 1.8V and 3V supported

- LTE Cat.1 features:

- Frequency bands

- LTE-FDD: bands 1, 3, 5, and 8

- LTE-TDD: bands 34, 38, 39, 40, and 41

- Data transmission rate

- LTE-FDD: Maximum download speed of 10 Mbit/s, and maximum upload speed of 5 Mbit/s

- LTE-TDD: Maximum download speed of 8.2 Mbit/s, and maximum upload speed of 3.4 Mbit/s

- Transmit power: 23 dBm ± 2 dBm

- Receiving sensitivity: less than -99 dBm

- 50Ω antenna impedance, with an external antenna required

- Frequency bands

- Interfaces:

- 1 USB 2.0 interface

- 3 UART interfaces

- 2 I2C interfaces*

- 1 I2S interface*

- 1 SPI display interface*

- 1 SPI camera interface*

- 2 ADC interfaces

- Operating temperature range: -30°C to +75°C 1

- Extended temperature range: -40°C to +85°C 2

- Update firmware over the air.

- *: The module currently only supports data transmission through AT commands, while other features are unavailable. 1: Within the operating temperature range, the module is 3GPP compliant.

- 2: Within the extended temperature range, the module is able to work properly. Only the values of one or several RF parameters might exceed the specified tolerances of 3GPP specifications.

Scope of applications

- Public utilities: smart metering (water, gas, and electricity), smart water management (pipe network, leakage, and quality inspection), smart fire extinguisher, and smart fire hydrant.

- Smart health: medication tracker, remote patient monitoring, blood pressure monitor, blood glucose meter, health-tracking wearables, and baby monitor.

- Smart city: smart street lighting, smart parking, smart waste bin, public security alarm, and environment monitoring (water pollution, noise, air quality PM2.5, and more).

- Consumer electronics: wearable, bicycle, GPS tracker (children, the elderly, pets, and car rental), smart suitcase, and POS machine.

- Agriculture and environment: precision planting (environmental parameters: water, temperature, light, medicine, fertilizer), livestock farming (health and tracking), aquaculture, and food quality monitoring.

- Logistics and warehousing: asset and container tracking, warehouse management, fleet tracking, and courier tracking.

- Smart buildings: access control, smart heating, ventilation, and air conditioning (HVAC), smoke detector, fire alarm, and elevator repair and maintenance.

- Manufacturing: equipment monitoring, energy monitoring, chemicals plants monitoring, large rental equipment, and predictive maintenance (home appliance and machinery).

Module interfaces

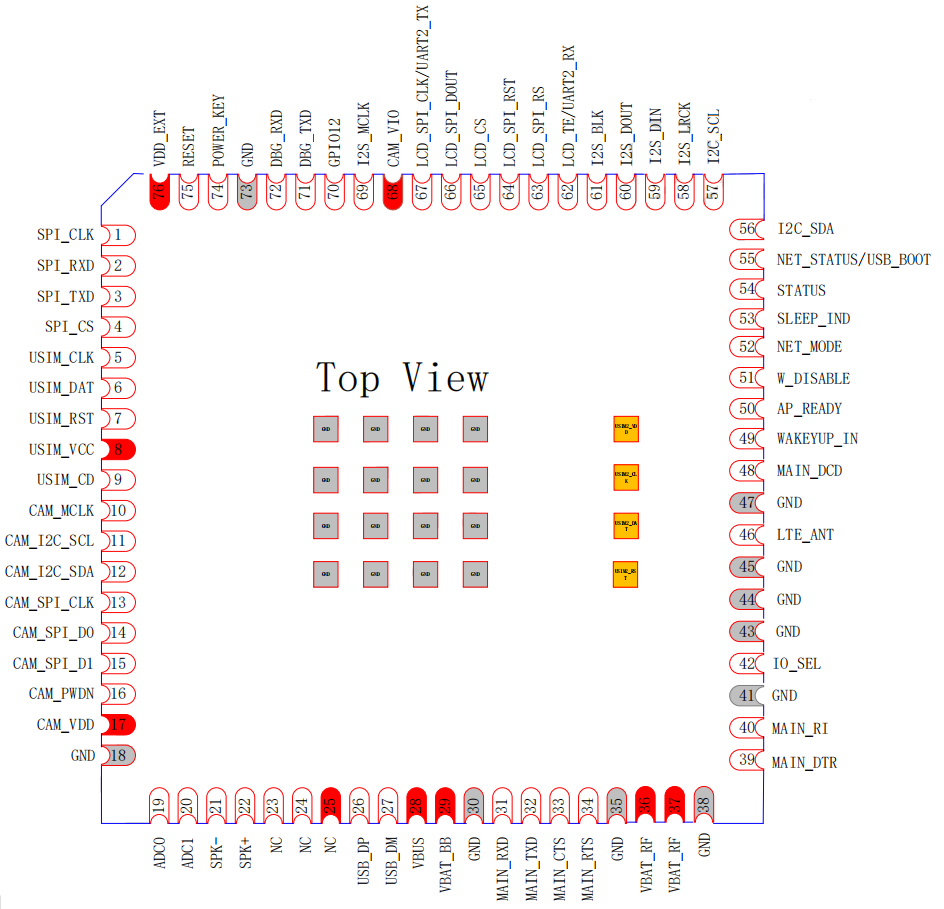

Pin definition

TCS600E is equipped with a total of 96 pins, including LCC pins and LGA pins.

The pinout is as follows:

Pin definition

| Pin No. | Pin name | I/O type | Description |

|---|---|---|---|

| 1 | SPI_CLK* | DO | SPI1 clock signal output. It cannot be used with Pin 71 DBG_TXD simultaneously. |

| 2 | SPI_RXD* | DI | SPI1 data input. It cannot be used with Pin 72 DBG_RXD simultaneously. |

| 3 | SPI_TXD* | DO | SPI1 data output. It cannot be used with Pin 11 CAM_I2C_SCL simultaneously. |

| 4 | SPI_CS* | DO | SPI1 chip select signal. It cannot be used with Pin 12 CAM_I2C_SDA simultaneously. |

| 5 | USIM_CLK | DO | USIM card clock signal. |

| 6 | USIM_DATA | IO | USIM card data signal. |

| 7 | USIM_RST | DO | USIM card reset signal. |

| 8 | USIM_VDD | PO | Power supply for the USIM card. Either 1.8V or 3.0V is supported by the module automatically. IOMAX = 50 mA. |

| 9 | USIM_CD | DI | USIM card insertion detection. |

| 10 | CAM_MCLK* | DO | Camera master clock (MCLK) output. |

| 11 | CAM_I2C_SCL* | IO | Camera I2C clock signal, which can also be used as a general-purpose I2C interface. |

| 12 | CAM_I2C_SDA* | IO | Camera I2C data signal, which can also be used as a general-purpose I2C interface. |

| 13 | CAM_SPI_CLK* | DI | SPI camera clock input. It cannot be used with Pin 145 USIM2_RST simultaneously. |

| 14 | CAM_SPI_D0* | DI | SPI camera data input 0. It cannot be used with Pin 146 USIM2_DAT simultaneously. |

| 15 | CAM_SPI_D1* | DI | Camera SPI data input 1. |

| 16 | CAM_PWDN* | DO | Power down the camera. It cannot be used with Pin 147 USIM2_CLK simultaneously. |

| 17 | CAM_VDD* | PO | Analog power supply for the camera, defaulting to 2.8V. IOMAX = 100 mA. |

| 18 | GND | - | Ground. |

| 19 | ADC0 | AI | Analog-to-digital converter (ADC). Input voltage: 0 to 3.4V Channel: 0 Resolution: 12 bits |

| 20 | ADC1 | AI | Analog-to-digital converter (ADC). Input voltage: 0 to 3.4V Channel: 1 Resolution: 12 bits |

| 21 | SPK-* | AO | Negative audio differential output, with no built-in power amplifier. It can drive a 32Ω receiver. An external power amplifier is required to connect to an 8Ω external speaker. |

| 22 | SPK+* | AO | Positive audio differential output, with no built-in power amplifier. It can drive a 32Ω receiver. An external power amplifier is required to connect to an 8Ω external speaker. |

| 23 | NC | - | Reserved. |

| 24 | NC | - | Reserved. |

| 25 | NC | - | Reserved. |

| 26 | USB_DP | IO | Positive USB differential signal, which should have a 90Ω differential impedance. |

| 27 | USB_DM | IO | Negative USB differential signal, which should have a 90Ω differential impedance. |

| 28 | USB_VBUS | DI | USB insertion detection, active high. It can work in sleep state. |

| 29 | VBAT_BB | PI | Power supply for the module baseband part. Supply voltage range: 3.4V to 4.3V. Nominal voltage: 3.8V. The external power supply should output a 500 mA current. It is recommended to add a surge protector. |

| 30 | GND | - | Ground. |

| 31 | MAIN_RXD | DI | The main UART interface used for receiving data. It can wake up the module in sleep state. |

| 32 | MAIN_TXD | DO | The main UART interface used for transmitting data. It can wake up the module in sleep state. |

| 33 | MAIN_CTS | DO | DTE main UART clear to send, connected to DTE’s CTS. |

| 34 | MAIN_RTS | DI | DTE main UART request to send, connected to DTE’s RTS. |

| 35 | GND | - | Ground. |

| 36 | VBAT_RF | PI | Power supply for the module RF part. Supply voltage range: 3.4V to 4.3V. Nominal voltage: 3.8V. The external power supply should output a 1A current. It is recommended to add a surge protector. |

| 37 | VBAT_RF | PI | Power supply for the module RF part. Supply voltage range: 3.4V to 4.3V. Nominal voltage: 3.8V. The external power supply should output a 1A current. It is recommended to add a surge protector. |

| 38 | GND | - | Ground. |

| 39 | MAIN_DTR | DI | Sleep or wake-up control. Pull up this pin, and the module is put into sleep mode. Pull down this pin, and the module in sleep mode can be woken up. |

| 40 | MAIN_RI | DO | Main UART ring indicator. It can be used to wake up the AP. It can remain active in sleep mode. |

| 41 | GND | - | Ground. |

| 42 | IO_SEL | DI | Voltage selection pin. The voltage is 1.8V when the pin is floating, and 3.3V when it is grounded with a 0Ω resistor. This pin affects the level of all I/O ports. |

| 43 | GND | - | Ground. |

| 44 | GND | - | Ground. |

| 45 | GND | - | Ground. |

| 46 | LTE_ANT | AIO | LTE antenna output, with 50Ω characteristic impedance. |

| 47 | GND | - | Ground. |

| 48 | MAIN_DCD | DO | Output carrier detection of main UART. |

| 49 | WAKEUP_IN* | DI | Sleep or wake-up control. |

| 50 | AP_READY | DI | Detect the sleep state of the application processor. |

| 51 | W_DISABLE | DI | Enable or disable the airplane mode. |

| 52 | NET_MODE | DO | Indicate the mobile network standard under which the module is registered. |

| 53 | SLEEP_IND* | DO | Sleep mode indicator. |

| 54 | STATUS | DO | Running status indicator. |

| 55 | NET_STATUS/USB_BOOT | DO | Pulling up this pin to VDD_EXT before power-on will make the module enter USB download mode. After power-on, it indicates the network status, and pulling up is prohibited. |

| 56 | I2C2_SDA | IO | I2C2 data signal. |

| 57 | I2C2_SCL | IO | I2C2 clock signal. |

| 58 | I2S_LRCK | DO | Switch the data of the left and right channels. If the value of LRCK is 0, it means that the data of the left channel is being transmitted, and the value of 1 means that the data of the right channel is being transmitted. |

| 59 | I2S_DIN | DI | I2S data input. |

| 60 | I2S_DOUT | DO | I2S data output. |

| 61 | I2S_BCK | DO | I2S bus clock line. |

| 62 | LCD_TE*/UART2_RX | DO | SPI LCD frame sync signal, or an extended serial port to receive data. |

| 63 | LCD_SPI_RS* | DO | SPI LCD data command selection. |

| 64 | LCD_SPI_RST* | DO | SPI LCD reset signal. |

| 65 | LCD_CS* | DO | SPI LCD chip select signal. |

| 66 | LCD_SPI_DOUT* | DO | SPI LCD data signal. |

| 67 | LCD_SPI_CLK*/UART2_TX | DO | SPI LCD clock signal, or an extended serial port to transmit data. |

| 68 | CAM_VIO* | PO | Camera I/O power supply, defaulting to 1.8V. |

| 69 | I2S_MCLK | DO | I2S interface reference clock. |

| 70 | GPIO12* | IO | Normal GPIO pin. |

| 71 | DBG_TXD | DO | Debugging interface, used to transmit data. |

| 72 | DBG_RXD | DI | Debugging interface, used to receive commands. |

| 73 | GND | - | Ground. |

| 74 | POWER_KEY | DI | Control the module power on/off, with an internal pull-up to VBAT. Pull down for more than 1.2s in power-off state to power on the module, and pull down for more than 1.5s in power-on state to power off the module. |

| 75 | RESET | DI | Reset the module, active low, with an internal pull-up to VBAT. |

| 76 | VDD_EXT | PO | LDO output, configured with Pin 42 hardware. This pin outputs 3.3V or 1.8V (the default value is 1.8V), and the maximum current is 200 mA. This pin is disabled in sleep state. High pulse is output frequently in sleep state, so this pin cannot be used as a module wake-up pin or serial port pull-up. |

| 77~92 | GND | - | Ground. |

| 145 | USIM2_RST | DO | USIM2 card reset signal. |

| 146 | USIM2_DATA | IO | USIM2 card data signal. |

| 147 | USIM2_CLK | DO | USIM2 card clock signal. |

| 148 | USIM2_VDD | PO | USIM2 card power supply |

*: The module currently only supports data transmission through AT commands, while other OpenCPU features are unavailable.

Electrical parameters

Absolute electrical parameters

| Parameter | Description | Min value | Max value | Unit |

|---|---|---|---|---|

| VBAT | Supply voltage | -0.3 | 4.7 | V |

| VBUS | USB detection | -0.3 | 5.5 | V |

| Ipk | Power supply peak current | 0 | 1.5 | A |

| Vio | Voltage of digital interface | -0.3 | VDDIO + 0.3 | V |

| Vadc | Voltage of analog interface | -0.3 | 4.7 | V |

Normal operating conditions

| Parameter | Description | Min value | Typical value | Max value | Unit |

|---|---|---|---|---|---|

| VBAT | Operating voltage | 3.3 | 3.8 | 4.3 | V |

| VBATdrop | Voltage drop at maximum power | - | - | 400 | mV |

| VBUS | USB detection | 3.3 | 5.0 | 5.25 | V |

| IVBAT | Peak current | - | 1.2 | 1.5 | A |

Operating and storage temperature

| Parameter | Description | Min value | Max value | Unit |

|---|---|---|---|---|

| Ts | Storage temperature | -40 | 90 | °C |

| Ta | Normal operating temperature3 | -35 | 75 | °C |

| Ta | Extended operating temperature4 | -40 | 85 | °C |

- 3: Within the operating temperature range, the module is 3GPP compliant.

- 4: Within the extended temperature range, the module is able to operate properly. Only the values of one or several RF parameters might exceed the specified tolerances of 3GPP specifications.

Direct current parameters

| Parameter | Description | Min value | Typical value | Max value | Unit |

|---|---|---|---|---|---|

| VIL | I/O low-level input | - | - | 0.3 × VDDIO | V |

| VIH | I/O high-level input | 0.7 × VDDIO | - | VDDIO | V |

| VOL | I/O low-level output | - | - | 0.2 × VDDIO | V |

| VOH | I/O high-level output | 0.8 × VDDIO | - | VDDIO | V |

Power consumption during standby and continuous transmission

-

Test instrument: R&S CMW500 wideband radio communication tester, and programmable power supply Agilent 66319D

-

Test conditions: VBAT=3.8V, ambient temperature 25°C. Insert a blank card, and connect to R&S CMW500 wideband radio communication tester.

| Parameter | Condition | Average value | Unit |

| Leakage current | A device is powered on for the first time. | 1 | μA |

| Power on and then power off (RTC works properly) | 1 | μA | |

| Standby current | LTE-TDD paging cycle 64 | 0.6 | mA |

| LTE-FDD paging cycle 128 | 0.45 | mA | |

| Continuous transmit current (TX power = 23 dBm) | B1 | 424 | mA |

| B3 | 406 | mA | |

| B5 | 389 | mA | |

| B8 | 434 | mA | |

| B34 | 172 | mA | |

| B38 | 234 | mA | |

| B39 | 164 | mA | |

| B40 | 263 | mA | |

| B41 | 236 | mA |

Power consumption of simulated persistent connections over real network

-

Test instrument: programmable power supply Agilent 66319D

-

Test conditions: VBAT=3.8V, ambient temperature 25°C

| Test environment | Real network under normal temperature | China Mobile BAND40 | China Unicom BAND1 | China Telecom BAND1 |

| Paging cycle | 0.64s | 1.28s | 1.28s | |

| Signal quality | AT + CESQ | 60 | 54 | 54 |

| Sleep current | AT + CSCLK = 2 | 0.58 mA | 0.45 mA | 0.43 mA |

| TCP keep-alive heartbeat packet | AT + CSCLK = 2, once a minute | 2.74 mA | 2.71 mA | 2.57 mA |

| AT + CSCLK = 2, every five minutes | 1.05 mA | 0.94 mA | 0.93 mA | |

| TCP keep-alive heartbeat packet (ultra low power mode) | AT + CSCLK = 3, once a minute (AT + WAKETIM = 1, AT × RTIME = 1) | 1.27 mA | 0.97 mA | 1.13 mA |

| AT + CSCLK = 3, every five minutes (AT + WAKETIM = 1, AT × RTIME = 1) | 0.74 mA | 0.61 mA | 0.68 mA |

RF parameters

Basic RF features

| Parameter | Description |

|---|---|

| LTE-FDD frequency band | LTE-FDD: bands 1, 3, 5, and 8 |

| LTE-TDD frequency band | LTE-TDD: bands 34, 38, 39, 40, and 41 |

| Wireless standard | 3GPP Release 13 |

| LTE-FDD speed | Maximum download speed of 10 Mbit/s Maximum upload speed of 5 Mbit/s |

| LTE-TDD speed | Maximum download speed of 8.2 Mbit/s Maximum upload speed of 3.4 Mbit/s |

| Antenna type | 50Ω characteristic impedance |

Transmission performance

Continuous transmission performance

| Frequency bands | Min value | Max value | Unit |

|---|---|---|---|

| LTE-FDD B1 | <-44 | 23 ± 2 | dBm |

| LTE-FDD B3 | <-44 | 23 ± 2 | dBm |

| LTE-FDD B5 | <-44 | 23 ± 2 | dBm |

| LTE-FDD B8 | <-44 | 23 ± 2 | dBm |

| LTE-TDD B34 | <-42 | 23 ± 2 | dBm |

| LTE-TDD B38 | <-42 | 23 ± 2 | dBm |

| LTE-TDD B39 | <-42 | 23 ± 2 | dBm |

| LTE-TDD B40 | <-42 | 23 ± 2 | dBm |

| LTE-FDD B41 | <-42 | 23 ± 2 | dBm |

Receiving performance

Receiving sensitivity:

| Frequency bands | Typical value | Unit |

|---|---|---|

| LTE-FDD B1 (10 Mbit/s) | -99 | dBm |

| LTE-FDD B3 (10 Mbit/s) | -99 | dBm |

| LTE-FDD B5 (10 Mbit/s) | -99 | dBm |

| LTE-FDD B8 (10 Mbit/s) | -99 | dBm |

| LTE-FDD B34 (10 Mbit/s) | -99 | dBm |

| LTE-FDD B38 (10 Mbit/s) | -99 | dBm |

| LTE-FDD B39 (10 Mbit/s) | -99 | dBm |

| LTE-FDD B40 (10 Mbit/s) | -99 | dBm |

| LTE-FDD B41 (10 Mbit/s) | -99 | dBm |

Electrostatic discharge (ESD) protection

During the application of the module, static electricity is generated by the human body and charged friction between microelectronics and then discharged to the module in various ways. This might damage the module, so ESD protection must be taken seriously. ESD protection measures should be taken in the process of production assembly, testing, research and development, especially in product design. For example, ESD protection is added at the interfaces or ESD-sensitive points in the circuit design, and anti-ESD gloves are worn during production.

| Location | Air discharge | Contact discharge |

|---|---|---|

| VBAT, GND | ±10 kV | ±5 kV |

| Antenna interface | ±10 kV | ±5 kV |

| Others | ±1 kV | ±0.5 kV |

Antenna information

Antenna type

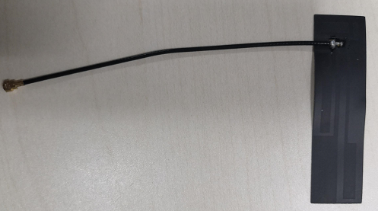

This module does not come with an antenna, so an external antenna is required.

You can choose one from the external rubber antenna, helical antenna, FPC antenna with IPEX connector, and PCB antenna. The antenna can typically be a monopole antenna, planar inverted-F antenna (PIFA), inverted-F antenna (IFA), and loop antenna.

-

Rubber antenna:

-

FPC antenna with IPEX connector:

-

Built-in FPC antenna

Antenna design requirements

- Make sure the characteristic impedance of the transmission line is 50Ω.

- The antenna line loss should be less than 0.3 dB. Thus, keep the PCB trace as short as possible.

- The PCB layout should be as straight as possible to avoid vias and layer changes. Also, steer clear of right-angle and sharp-angle traces.

- A good reference ground should be set around the PCB traces, and other signal lines should be kept away from the antenna.

- A complete ground is recommended as a reference ground.

- The ground plane around the antenna must reinforce its connection to the main ground plane of the motherboard.

- The distance between the antenna and other mental components should be at least 10 mm.

Antenna metrics

| Parameter | Metrics |

|---|---|

| VSWR | ≤ 2 |

| Efficiency | > 30% |

| Input impedance | 50Ω |

| Insertion loss (<1 GHz) | <1 dB |

| Insertion loss (1 to 2.3 GHz) | <1.5 dB |

| Insertion loss (> 2.3 GHz) | <2.0 dB |

Packing and production instructions

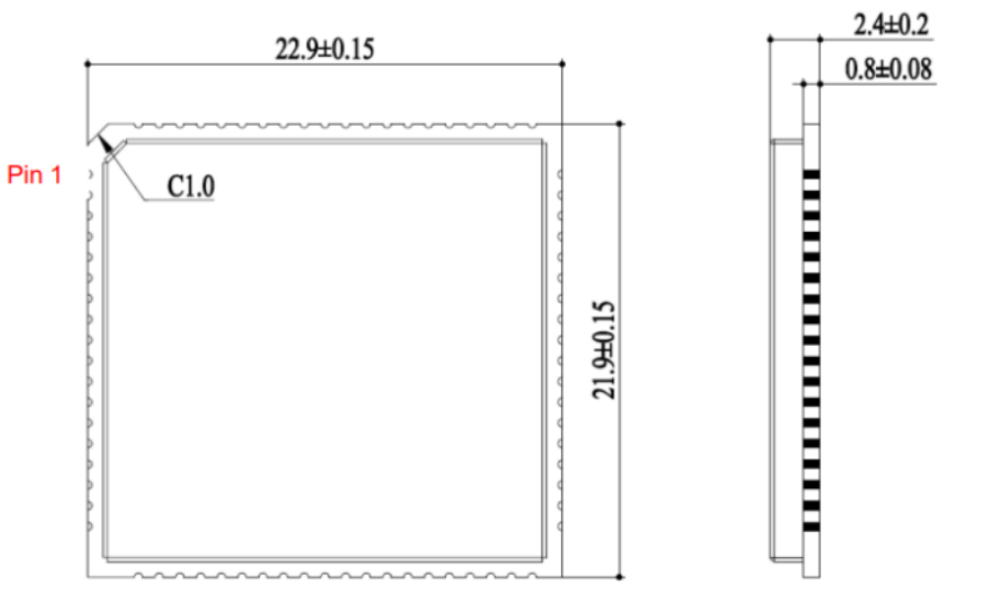

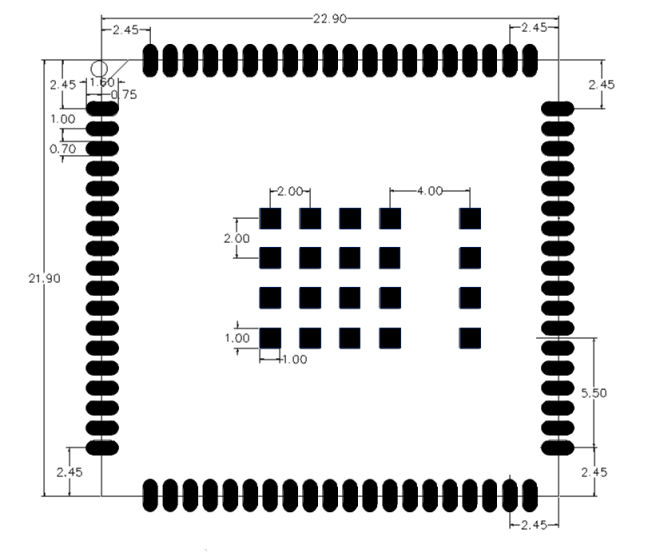

Mechanical dimensions

TCS600E is equipped with a total of 96 pins, including 76 leadless chip carrier (LCC) pins and 20 land grid array (LGA) pins.

The dimensions are 21.9 mm±0.35 (W) × 22.9 mm±0.35 (L) × 2.4 mm±0.15 (H), as shown below. The PCB thickness is 0.8 mm±0.1 mm.

SMT package

Stencil opening design

- Stencil thickness: The stencil thickness of the area for the module should be partly stepped up to 0.18 mm–0.2 mm. The stencil thickness in other positions is determined by product design.

- LCC pins: The stencil openings are shrunk inward by 0.1 mm, and moved outward by 1 mm along the direction of length. Along the width direction, the stencil openings are shrunk inward by 0.16 mm (each side by 0.08 mm) with a length of 1.4 mm (module’s pin length, avoiding solder beads), and are moved outward by 0.2 mm (each side by 0.1 mm) with a length of 2 mm (exposed on the areas outside of the bottom of the module pins must get increased tinning).

- LGA pins: The total opening area should be 60% of the pad. If it exceeds 60%, you can set a pitch of 0.3 mm.

Production instructions

-

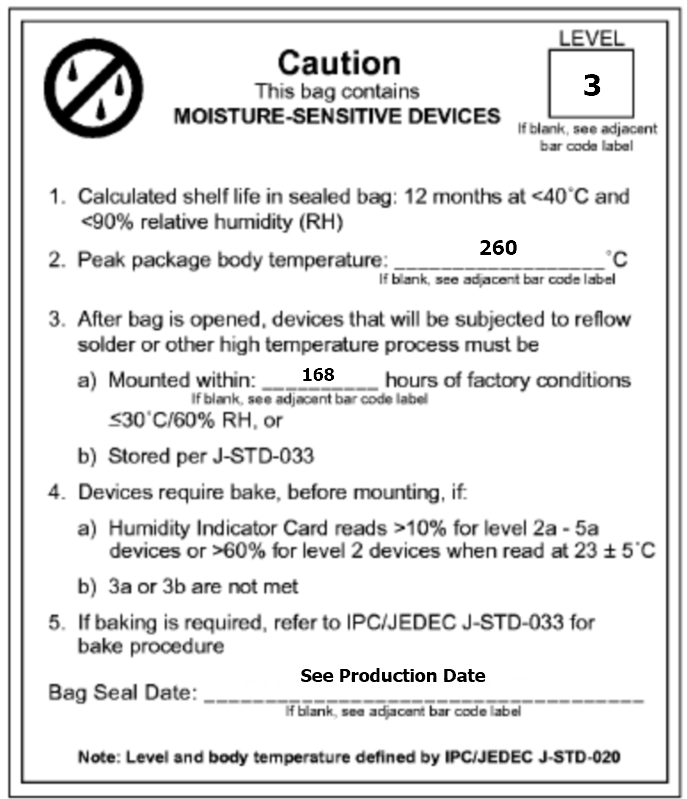

Package the module with the SMT if Tuya’s module is designed to be SMT-packaged. After being unpacked, the module must be soldered within 24 hours. Otherwise, it needs to be put into a drying cupboard with a relative humidity level no greater than 10%, or pack the module in vacuum again. Then, record the packing time and duration of exposure. The total exposure time cannot exceed 168 hours.

- Instruments or devices required for the SMT process:

- Surface mount system

- SPI

- Reflow soldering machine

- Thermal profiler

- AOI

- Instruments or devices required for the baking process:

- Cabinet oven

- Anti-electrostatic and heat-resistant trays

- Anti-electrostatic and heat-resistant gloves

- Instruments or devices required for the SMT process:

-

A delivered module must meet the following storage requirements:

-

The moisture-proof bag must be placed in an environment where the temperature is below 40°C and the relative humidity is lower than 90%.

-

The shelf life of a dry-packaged product is 12 months from the date when the product is packaged and sealed.

-

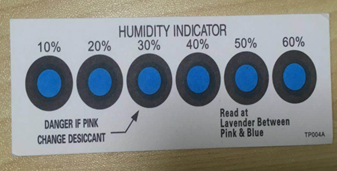

A humidity indicator card (HIC) is put in the sealed package.

-

-

The module needs to be baked in the following cases:

- The vacuum packaging bag is damaged before unpacking.

- After unpacking, no HIC is found in the packaging bag.

- After unpacking, the HIC indicates a humidity level of 10% or higher. In this case, the circle turns pink on the HIC.

- The total exposure time has lasted for over 168 hours since unpacking.

- More than 12 months have passed since the first sealing of the bag.

-

The baking parameter settings are described below:

- Baking temperature: 40°C for reel packaging with relative humidity ≤ 5%. And 125°C for tray packaging with relative humidity ≤ 5% (use the heat-resistant tray, rather than plastic containers).

- Baking time: 168 hours for reel packaging and 12 hours for tray packaging.

- Temperature for triggering an alert: 50°C for reel packaging and 135°C for tray packaging.

- Production can begin after a module has cooled down to below 36°C under natural conditions.

- If a module remains unused for over 168 hours after being baked, it needs to be baked again.

- If a batch of modules is not baked after exposure for more than 168 hours, do not use reflow soldering to solder them. Because these modules are level-3 moisture-sensitive devices, they are very likely to get damp when exposed beyond the allowable time. In this case, if they are soldered at high temperatures, device failure or poor soldering performance might occur.

-

In the whole production process, take electrostatic discharge (ESD) protective measures.

-

To guarantee the pass rate, we recommend that you use the SPI and AOI to monitor the quality of solder paste printing and mounting.

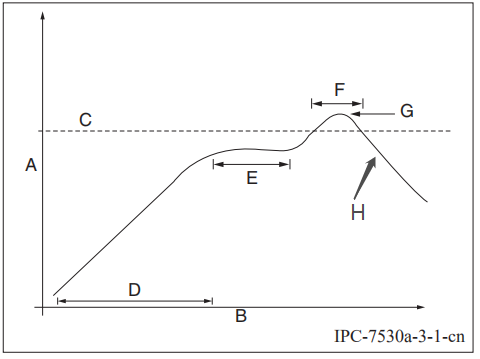

Recommended oven temperature curve

Perform the SMT process according to the following temperature curve of reflow soldering. The peak temperature is 245°C.

-

A: temperature axis

-

B: time axis

-

C: alloy liquidus temperature from 217°C to 220°C

-

D: ramp-up slope from 1°C/s to 3°C/s

-

E: keep a constant temperature from 150°C to 200°C for a time period from 60s to 120s

-

F: temperature above liquidus temperature for 50s to 70s

-

G: peak temperature from 235°C to 245°C

-

H: ramp-down slope from 1°C/s to 4°C/s

The curve above is based on solder paste SAC305. For more information about other solder pastes, see the recommended oven temperature curve in the specified solder paste specifications.

Storage conditions

MOQ and packaging information

| Product model | MOQ (pcs) | Shipping packaging | Modules per reel | Reels per carton |

|---|---|---|---|---|

| TCS600E | 3,500 | Tape and reel | 700 | 5 |

Is this page helpful?

YesFeedbackIs this page helpful?

YesFeedback