LZ501-CN Module Datasheet

Last Updated on : 2024-06-14 07:47:27download

LZ501-CN is an LTE Cat.1 cellular module that Tuya has developed. Embedded with the LTE CAT.1 network communication protocol stack and rich library functions, it includes a highly integrated LTE Cat.1 chip (UIS8910DM) and peripheral circuits.

Product overview

LZ501-CN has the Cortex A5 processor and Cat.1bis modem inside and is integrated with the 64-MB Nor flash memory and 128-MB PSRAM. It supports interfaces including USB, UART, SDIO, SPI, I2C, I2S, and ADC. Besides, it also supports peripherals, including display, camera, keyboard matrix, microphone, speaker, charging, card, and USIM card.

Features

- Cortex A5 processor with the clock rate of CPU: 500 MHz

- Supply voltage:

- Operating voltage: 3.4 to 4.3V

- Typical operating voltage: 3.8 V

- Supported SIM card: 1.8V/3V

- Features of LTE Cat.1:

Frequency band- LTE-FDD: B1/B3/B5/B8

- LTE-TDD: B34/38/39/40/41 (2535 to 2655 MHz)

- Data rate

- LTE-FDD: Max 10 Mbit/s (downlink)/Max 5 Mbit/s (uplink)

- LTE-TDD: Max 8.2 Mbit/s (downlink)/Max 3.4 Mbit/s (uplink)

- Transmit power: 23 ± 2 dBm

- Receiving sensitivity: Less than -97 dBm

- Antenna impedance 50Ω, an external antenna required

- Bluetooth LE 4.2

- Wi-Fi SCAN

- Interfaces:

- 1 USB 2.0

- 3 UARTs

- 1 I2Cs

- 1 PCM/I2S

- 2 ADCs

- Peripherals:

- SPI display screen with the resolution of QVGA 320x240 and 30 FPS

- SPI/MIPI camera with 300,000 pixels

- 4*5 keyboard matrix

- 1 microphone

- 1 speaker

- 1 headset

- Charging

- Normal operating temperature: -30°C to +75℃ 1

- Extended operating temperature: -40°C to +85℃ 2

- Support to upgrade firmware with the OTA technology

Note:

1 indicates that when the module is in the operating temperature range, the performance of the module can meet the 3GPP standard.

2 indicates that when the module is in the operating temperature range, the module can still work normally, but some RF indicators might slightly exceed the standard values specified in the 3GPP.

Applications

- Smart health: Drug traceability, remote medical monitoring, blood pressure meter, blood glucose meter, heart armour monitoring, baby monitor, etc.

- Smart city: Smart street lights, smart parking, urban trash can management, public safety alarms, urban environment monitoring (water pollution, noise, air quality PM2.5, etc.)

- Consumers: Wearable devices, bicycles, mopeds anti-theft, smart luggage, VIP tracking (children, elderly, pets and vehicle rental), and payment/POS machines

- Agricultural environment: Precision planting (environment parameters: water, temperature, sunshine, biocide and fertilizer), animal husbandry (health and tracking), aquaculture and food safety traceability

- Logistics warehousing: Asset, container tracking, warehouse management, fleet management tracking, and logistics status tracking.

- Smart building: Access control, smart HVAC, smoke detection, fire detection and elevator failure/repair

- Manufacturing industry: Production, equipment status monitoring, energy facilities, oil and gas monitoring, chemical park monitoring, large-scale rental equipment and predictive maintenance (home appliances, machinery, etc.)

- Public utilities: Meter reading (water, gas and electricity), intelligent water affairs (pipe network, leakage and quality inspection), smart fire extinguisher, fire hydrant, etc.

Module interfaces

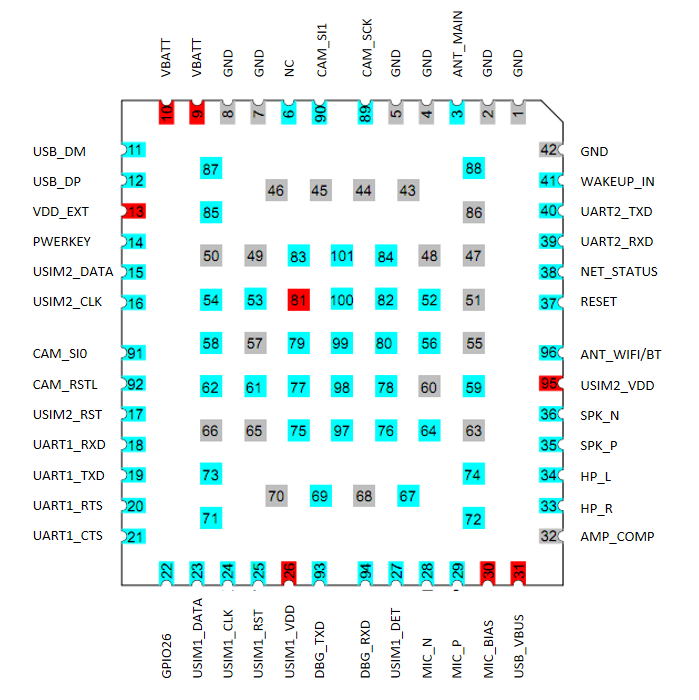

Pin distribution

LZ501-CN has 101 pins in total. Among them, there are 50 LCC-packaged pins and 51 LGA-packaged pins.

The diagram of correspondence between pin ID and pin name

Pin definition

| Pin number | Pin name | Signal type | Description |

|---|---|---|---|

| 1 | GND | - | Ground |

| 2 | GND | - | Ground |

| 3 | ANT_MAIN | AI/O | Interface for the main antenna |

| 4 | GND | - | Ground |

| 5 | GND | - | Ground |

| 6 | NC | - | - |

| 7 | GND | - | Ground |

| 8 | GND | - | Ground |

| 9 | VBAT | PI | Interface for battery or power supply (3.4-4.3V) |

| 10 | VBAT | PI | Interface for battery or power supply (3.4-4.3V) |

| 11 | USB_DM | I/O | USB Data Minus |

| 12 | USB_DP | I/O | USB Data Positive |

| 13 | VDD_EXT | PO | Power supply pin with output voltage of 1.8V |

| 14 | PWRKEY | I | Power on or off, low active |

| 15 | USIM2_DATA | I/O | Input and output interface for USIM2 data signal In OpenCPU mode, it can be used as GPIO 30. |

| 16 | USIM2_CLK | O | Output interface for USIM2 clock signal In OpenCPU mode, it can be used as GPIO 29. |

| 17 | USIM2_RST | O | Output interface for USIM2 reset signal In OpenCPU mode, it can be used as GPIO 31. |

| 18 | UART1_RXD | I | UART1: Receive data. Support the MCU. |

| 19 | UART1_TXD | O | UART1: Transmit data. Support the MCU. |

| 20 | UART1_RTS | I | UART1: Request to send. In OpenCPU mode, it can be used as GPIO 19. |

| 21 | UART1_CTS | O | UART1: Clean to send. In OpenCPU mode, it can be used as GPIO 18. |

| 22 | GPIO26 | I/O | GPIO26 |

| 23 | USIM1_DATA | I/O | USIM1 data |

| 24 | USIM1_CLK | O | Output interface for USIM1 clock signal |

| 25 | USIM1_RST | O | Output interface for reset signal |

| 26 | USIM1_VDD | PO | Power supply interface for USIM1 |

| 27 | USIM1_DET | I | Used to detect the hot swap of the USIM card. Pulled up externally to VDD_EXT when it is used. Not connected to anything when it is not used. |

| 28 | MIC_N | I | MIC Negative |

| 29 | MIC_P | I | MIC Positive |

| 30 | MIC_BIAS | PO | The interface for outputting the bias voltage of the MIC. It is not internally connected, and if externally used, it must be connected to the MIC signal. |

| 31 | USB_VBUS | PI | Pin for USB plug-in detection |

| 32 | AMP_COMP | - | Ground |

| 33 | HP_R | O | Interface for outputting signals of the right channel of the headphone |

| 34 | HP_L | O | Interface for outputting signals of the left channel of the headphone |

| 35 | SPK_P | O | Speaker (+) |

| 36 | SPK_N | O | Speaker (-) |

| 37 | RESET | I | Module reset signal, low active |

| 38 | NET_STATUS* | O | Used to indicate the network running status. In OpenCPU mode, it can be used as GPIO 9. |

| 39 | UART2_RXD | I | Serial interface 2 for receiving data. In OpenCPU mode, it can be used as GPIO 20. |

| 40 | UART2_TXD | O | Serial interface 2 for transmitting data. In OpenCPU mode, it can be used as GPIO 21. |

| 41 | WAKEUP_IN | I | Wakeup pin, used by the external device to wake up the module. Not connected to anything when it is not used. In OpenCPU mode, it can be used as GPIO 10 |

| 42 to 51 | GND | - | Ground |

| 52 | I2C2_SDA | IO | I2C data signal In OpenCPU mode, it can be used as GPIO 17. |

| 53 | KEYOUT0 | I/O | Key output 0 |

| 54 | LCD_CLK | O | SPI LCD clock signal |

| 55 | GND | - | Ground |

| 56 | I2C2_SCL | I/O | I2C clock signal |

| 57 | GND | - | Ground |

| 58 | LCD_SIO | O | SPI LCD serial input/output |

| 59 | ADC3 | AI | Interface 3 for analog-to-digital conversion |

| 60 | GND | - | Ground |

| 61 | WAKEUP_OUT* | O | Wakeup pin, used by the module to wake up the external device. Not connected to anything when it is not used. In OpenCPU mode, it can be used as GPIO 5. |

| 62 | LCD_SDC | O | SPI LCD selection of data command |

| 63 | GND | - | Ground |

| 64 | ADC2 | AI | Interface 2 for analog-to-digital conversion |

| 65 | GND | - | Ground |

| 66 | GND | - | Ground |

| 67 | ISENSE | I | Used to detect the current for charging. |

| 68 | GND | - | Ground |

| 69 | LCD_CS | O | SPI LCD chip selection |

| 70 | GND | - | Ground |

| 71 | USBBOOT | I/O | If you input 0 through the keyboard and pull the voltage to VDD_EXT before the module is powered on, the module will enter the USB download mode. |

| 72 | VBAT_SENSE | I | Used to detect the voltage of the battery. Try to get close to the positive of the battery as much as possible, and directly connect to the VBAT interface of the module when the battery is not used. Otherwise, the module will keep restarting. |

| 73 | VDRV | O | Control signal of the charging circuit |

| 74 | LCD_RSTB | O | SPI LCD reset signal |

| 75 | KEYOUT1 | I/O | Key output 1 |

| 76 | KEYOUT2 | I/O | Key output 2 |

| 77 | UART3_RXD/KEYOUT4 | I | Serial interface 3: Receive data and reuse KEYOUT4. |

| 78 | UART3_TXD/KEYOUT5 | O | Serial interface 3: Transmit data and reuse KEYOUT5. |

| 79 | CAM_PWDN | IO | Camera CAM_PWDN signal |

| 80 | CAM_REFCLK | O | Camera CAM_REFCLK signal |

| 81 | HEADMIC_BIAS | PO | The interface for outputting the bias voltage of the microphone. It is not connected internally, and if externally used, it must be connected to the HEADMIC signal. |

| 82 | PCM_DOUT | O | Used to output PCM voice data. In OpenCPU mode, it can be used as GPIO 3. |

| 83 | PCM_CLK | I/O | PCM voice clock signal. In OpenCPU, it can be used as GPIO 0. |

| 84 | PCM_SYNC | I/O | PCM voice synchronization signal. In OpenCPU mode, it can be used as GPIO 1. |

| 85 | PCM_DIN | I | Used to input PCM voice data. In OpenCPU mode, it can be used as GPIO 2. |

| 86 | GND | - | Ground |

| 87 | KEYOUT3 | I/O | Key output 3 |

| 88 | KEYIN3 | I/O | Key input 3 |

| 89 | CAM_SCK | IO | Camera CAM_SCK signal |

| 90 | CAM_SI1 | I/O | Camera CAM_SI1 signal |

| 91 | CAM_SI0 | I/O | Camera CAM_SI0 signal |

| 92 | CAM_RSTL | I/O | Camera CAM_RSTL signal |

| 93 | DBG_TXD | I | The pin is used for debugging and transmitting data. |

| 94 | DBG_RXD | O | The pin is used for debugging and receiving data. |

| 95 | USIM2_VDD | PO | Power supply interface for USIM2 |

| 96 | ANT_BT/WIFI | AI/O | Bluetooth and Wi-Fi antenna |

| 97 | WHTLED_IB0 | O | The pin for enabling the RGB LED light. In the open version, the current value can be configured. Imax=54mA |

| 98 | NET_MODE | PI | Used to indicate the network registration status. Flashing fast indicates “in the progress of searching for the network”. Flashing slowly indicates “already connected to the Tuya Cloud Platform”. |

| 99 | HEADMIC_P | I | Headmic Input Positive |

| 100 | HEADMIC_N | I | Headmic Input Negative |

| 101 | KEYIN4 | I/O | Key input 4 |

Note: P indicates a power supply pin and I/O indicates an input/output pin. “*” indicates that the function is not supported currently.

Electrical parameters

Absolute electrical parameters

| Parameter | Description | Minimum value | Maximum value | Unit |

|---|---|---|---|---|

| Ts | Storage temperature | -40 | 90 | ℃ |

| VBAT | Supply voltage | -0.3 | 4.6 | V |

ESD features

| Location | Air charge | Contact charge |

|---|---|---|

| GND | ±10 KV | ±5 KV |

| Antenna interface | ±8KV | ±4KV |

| Other interfaces | ±1 KV | ±0.5 KV |

Normal working conditions

| Parameter | Description | Minimum value | Typical value | Maximum value | Unit |

|---|---|---|---|---|---|

| Ta | Operating temperature | -30 | - | 75 | ℃ |

| Ta | Extended operating temperature | -40 | - | 85 | ℃ |

| VBAT | Operating voltage | 3.4 | 3.8 | 4.3 | V |

Direct-current parameters

1.8 V Digital I/O

| Parameter | Description | Minimum value | Typical value | Maximum value | Unit |

|---|---|---|---|---|---|

| VIL | Low-level input | - | - | 0.3*VCC | V |

| VIH | High-level input | 0.7*VCC | - | VCC | V |

| VOL | Low-level output | - | - | 0.2*VCC | V |

| VOH | High-level output | 0.8*VCC | - | VCC | V |

Power consumption of LTE at standby and constant-transmission states

| Working mode | Condition | Average value | Peak value (Typical value) | Unit |

|---|---|---|---|---|

| Standby current (general firmware) | LTE-TDD | 8.2 | - | mA |

| Standby current (general firmware) | LTE-FDD | 6.5 | - | mA |

| Standby current (OpenCPU firmware) | LTE-TDD | 7.8 | - | mA |

| Standby current (OpenCPU firmware) | LTE-FDD | 6.2 | - | mA |

| Constant transmission (23 dBm) | LTE-TDD | 420 | 650* | mA |

| Constant transmission (23 dBm) | LTE-FDD | 580 | 650* | mA |

Note: The 600-mA current is generated when the VBAT is in parallel connected to the 1000-uF capacitor. If there is no large capacitor, the peak current will be above 1A. So please pay attention to the power input.

RF parameters

Basic RF features

| Parameter | Description |

|---|---|

| LTE-FDD frequency band | LTE-FDD: B1/B3/B5/B8 |

| LTE-TDD frequency band | LTE-TDD: B34/B38/B39/B40/B41 |

| Wireless standard | 3GPP R13 |

| LTE-FDD rate | LTE-FDD: Max 10 Mbps (downlink)/max 5 Mbps (uplink) |

| LTE-TDD rate | LTE-TDD: Max 8.2 Mbps (downlink)/max 3.4 Mbps (uplink) |

| Antenna | Characteristic impedance of 50 Ω |

TX performance

Performance during constant transmission:

| Frequency band | Minimum value | Maximum value | Unit |

|---|---|---|---|

| LTE-FDD B1 | <-39 | 23±2 | dBm |

| LTE-FDD B3 | <-39 | 23±2 | dBm |

| LTE-FDD B5 | <-39 | 23±2 | dBm |

| LTE-FDD B8 | <-39 | 23±2 | dBm |

| LTE-TDD B34 | <-39 | 23±2 | dBm |

| LTE-TDD B38 | <-39 | 23±2 | dBm |

| LTE-TDD B39 | <-39 | 23±2 | dBm |

| LTE-TDD B40 | <-39 | 23±2 | dBm |

| LTE-FDD B41 | <-39 | 23±2 | dBm |

RX performance

Receiving sensitivity:

| Frequency band | Typical value | Unit |

|---|---|---|

| LTE-FDD B1 | -99 | dBm |

| LTE-FDD B3 | -99 | dBm |

| LTE-FDD B5 | -98 | dBm |

| LTE-FDD B8 | -97 | dBm |

| LTE-FDD B34 | -100 | dBm |

| LTE-FDD B38 | -100 | dBm |

| LTE-FDD B39 | -100 | dBm |

| LTE-FDD B40 | -100 | dBm |

| LTE-FDD B41 | -100 | dBm |

Antenna information

Antenna type

The module does not have its own onboard PCB antenna, so the third-party antenna is required.

The antenna can be an external rod antenna, a spring antenna, an IPEX-FPC antenna, a PCB board antenna, etc. The antenna forms include monopole antenna, PIFA antenna, IFA antenna, loop antenna, etc.

Rod antenna

FPC antenna

Requirements on antenna design

- Ensure that the characteristic impedance of the transmission line is 50Ω.

- Since the antenna line loss needs to be less than 0.3 dB, keep the PCB trace as short as possible.

- When designing the layout, you should choose the most direct and shortest route, avoiding routing through layers or holes, rectangles, or sharp angles.

- There is a good reference for the antenna, to keep away from other signal wires.

- It is recommended that you use the complete ground plane as the ground reference.

- Strengthen the connection between the ground around the antenna and the main ground.

- It is recommended that the antenna be at least 10 mm away from other metal parts.

Packaging information and production instructions

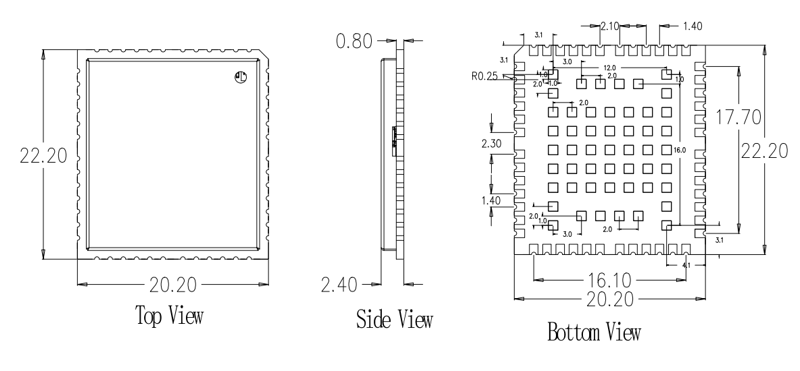

Mechanical dimensions

LZ501-CN has 101 pins in total. Among them, there are 50 LCC-packaged pins and 51 LGA-packaged pins.

The dimensions of LZ501-CN are 22.2±0.35 mm (W)×20.2±0.35 mm (L)×2.4±0.15 mm (H). The thickness of the PCB is 0.8±0.1 mm.

Mechanical dimensions and dimensions of the back of the pad

Note: The tolerance for the length and width of the module is ±0.35 mm, the height is ±0.15 mm, and the thickness is ±0.1 mm.

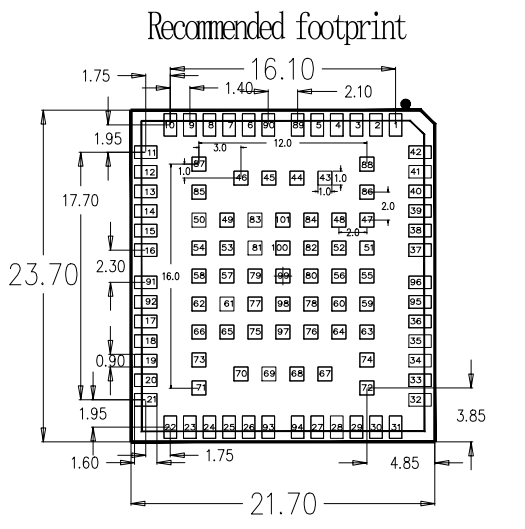

PCB footprint-SMT

Production instructions

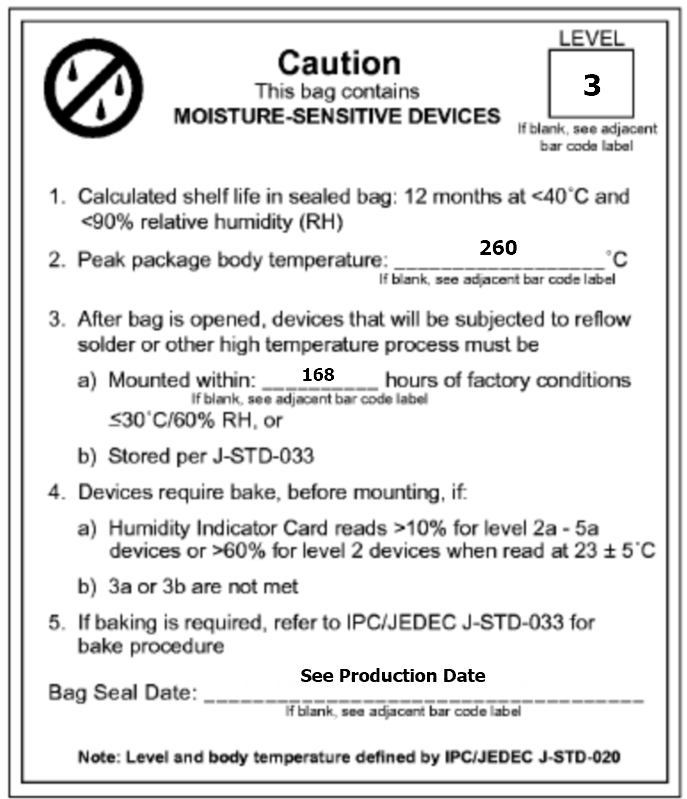

- The Tuya SMT module should be mounted by the SMT device. After being unpacked, it should be soldered within 24 hours. Otherwise, it should be put into the drying cupboard where the RH is not greater than 10%; or it needs to be packaged under vacuum again and the exposure time needs to be recorded (the total exposure time cannot exceed 168 hours).

- SMT devices:

- Mounter

- SPI

- Reflow soldering machine

- Thermal profilter

- Automated optical inspection (AOI) equipment

- Baking devices:

- Cabinet oven

- Anti-electrostatic and heat-resistant trays

- Anti-electrostatic and heat-resistant gloves

- SMT devices:

- Storage conditions for a delivered module:

-

The moisture-proof bag must be placed in an environment where the temperature is below 40°C and the relative humidity is lower than 90%.

-

The shelf life of a dry-packaged product is 12 months from the date when the product is packaged and sealed.

-

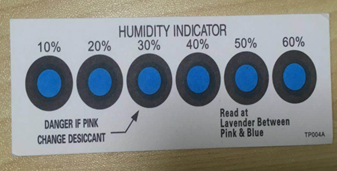

There is a humidity indicator card (HIC) in the packaging bag.

-

- The module needs to be baked in the following cases:

- The packaging bag is damaged before unpacking.

- There is no humidity indicator card (HIC) in the packaging bag.

- After unpacking, circles of 10% and above on the HIC become pink.

- The total exposure time has lasted for over 168 hours since unpacking.

- More than 12 months has passed since the sealing of the bag.

- Baking settings:

-Temperature: 60°C and ≤ 5%RH for reel package and 125°C and ≤5%RH for tray package (please use the heat-resistant tray rather than plastic container)- Time: 48 hours for reel package and 12 hours for tray package

- Alarm temperature: 65°C for reel package and 135°C for tray package

- Production-ready temperature after natural cooling: < 36°C

- Re-baking situation: If a module remains unused for over 168 hours after being baked, it needs to be baked again.

- If a batch of modules is not baked within 168 hours, do not use the reflow soldering to solder them. Because these modules are Level 3 moisture-sensitive devices, they are very likely to get damp when exposed outside. In this case, if they are soldered at high temperatures, it may result in device failure or poor soldering.

- In the whole production process, take electrostatic discharge (ESD) protective measures.

- To guarantee the passing rate, it is recommended that you use the SPI and AOI to monitor the quality of solder paste printing and mounting.

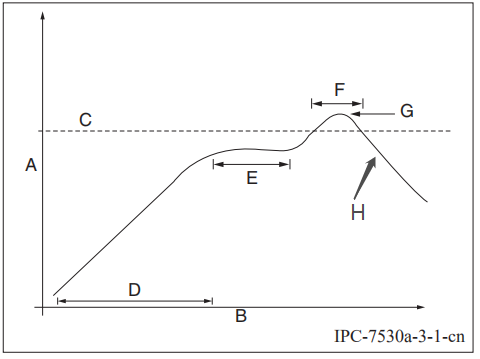

Recommended oven temperature curve

We mount the PCB with the SMT according to the following temperature curve. The peak temperature is 245°C.

-

A: Temperature axis

-

B: Time axis

-

C: Liquidus temperature: 217 to 220°C

-

D: Ramp-up slope: 1 to 3°C/s

-

E: Duration of constant temperature: 60 to 120s; the range of constant temperature: 150 to 200°C

-

F: Duration above the liquidus: 50 to 70s

-

G: Peak temperature: 235 to 245°C

-

H: Ramp-down slope: 1 to 4°C/s

Note: The above curve is just an example of the solder paste SAC305. For more details about other solder pastes, please refer to Recommended oven temperature curve in the solder paste specifications.

Storage conditions

MOQ and packaging information

| Product model | MOQ (pcs) | Packing method | Modules per reel | Reels per carton |

|---|---|---|---|---|

| LZ501-CN | 2800 | Tape reel | 700 | 4 |

Is this page helpful?

YesFeedbackIs this page helpful?

YesFeedback